A system for degreasing, derusting, and roughening of flat surface before coating

A surface coating and flat plate technology, which is applied in the direction of surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of poor pretreatment effect, etc., and achieve wide application range, high treatment efficiency and good treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

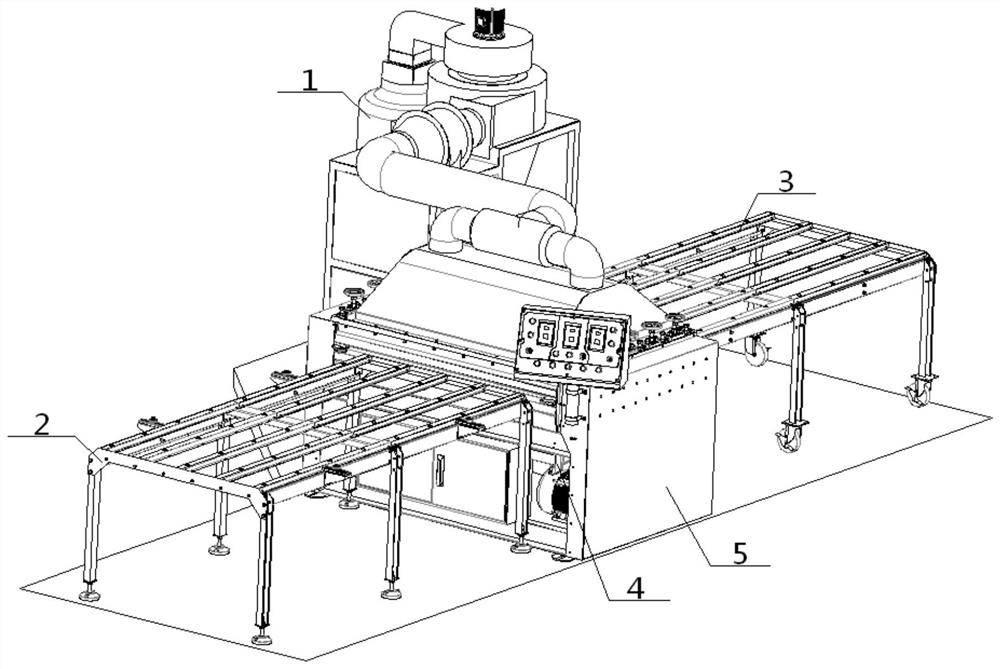

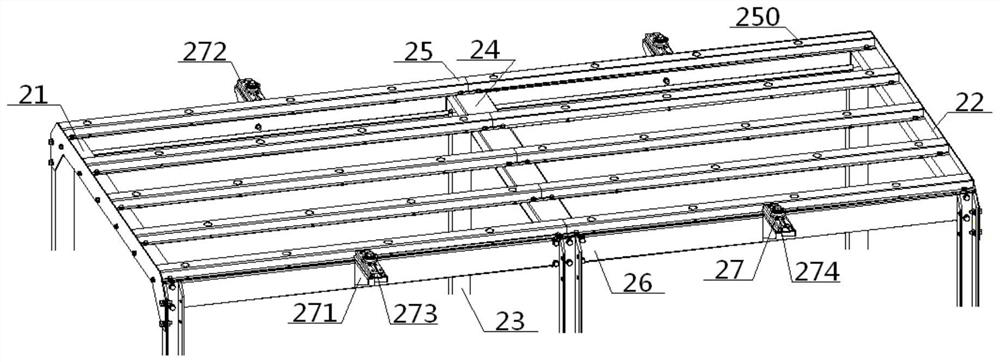

[0057] see figure 1 - Figure 28 , a system for degreasing, derusting, derusting and napping before surface coating of a flat plate, comprising a front fixed support frame 2, a pre-processing host 5, a rear movable support frame 3, a dust suction device 1 and a slag discharge device 4, the The pre-processing host 5 is provided with a plate passage area X and a clean passage area Y. The front fixed support frame 2 passes through the plate pass area X and the clean pass area Y successively, and communicates with the rear movable support frame 3 for dust collection. The device 1 is suspended directly above the pre-processing host 5, and the bottom of the pre-processing host 5 is connected to the top of the slag discharging device 4;

[0058] Described pre-processing main frame 5 comprises and comprises the upper brush roller 60 that co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com