Technology for printing and dyeing knitted polyester fabrics under conditions of high color fastness and little water

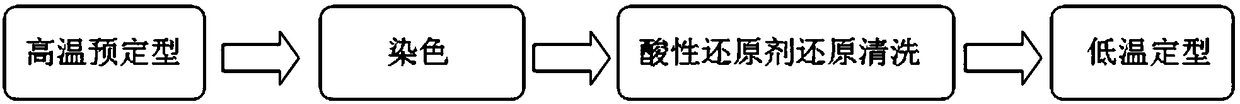

A technology of knitted fabrics and high color fastness, which is applied in the direction of fabric surface trimming, textile material treatment, and continuous processing of textile materials, etc., which can solve the problems of long production process, time-consuming, and high energy consumption, and achieve cost savings, Save water, reduce migration and sublimation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

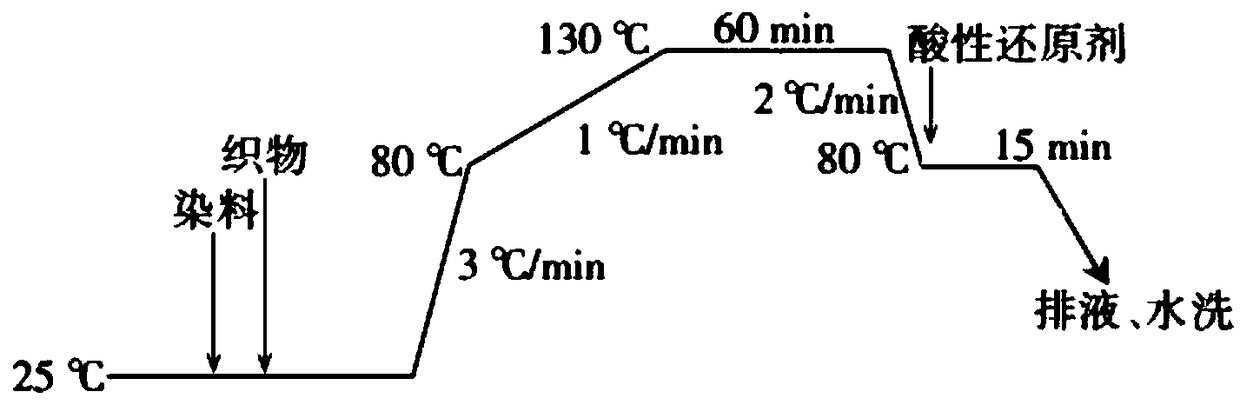

[0019] Embodiment 1: Polyester knitted fabric is pre-set through high temperature, and the temperature of each joint of the pre-setting setting machine is set as: 190 ℃ * 2 knots, 205 ℃ * 5 knots, 200 ℃, the speed of shaping machine is 38m / min, and the dyeing temperature is normal temperature with 3 ℃ / Min to raise the temperature to 80°C, then raise the temperature to 128°C at 1°C / min, keep warm for 60 minutes, then lower to 80°C at 2°C / min, add acid reducing agent 3g / l to reduce and wash for 15 minutes, wash with water and set the shape with wet cloth Temperature 120℃×6 knots. The results of testing the color fastness of polyester fabrics are: washing fastness 4-5 grades, sunlight fastness 4 grades, dry rubbing fastness 4 grades, wet rubbing fastness 3-4 grades.

Embodiment 2

[0020] Embodiment 2: polyester knitted fabric is pre-set through high temperature, and the temperature of each joint of the pre-setting setting machine is set as: 190 ℃ * 2 knots, 205 ℃ * 5 knots, 200 ℃, the setting speed of a vehicle is 40m / min, and the dyeing temperature is normal temperature at 3 ℃ / Min to raise the temperature to 80°C, then raise the temperature to 130°C at 1°C / min, keep warm for 50 minutes, and lower to 80°C at 2°C / min, add acid reducing agent 4g / l to reduce and wash for 15 minutes, wash with water and set the shape with wet cloth Temperature 125℃×6 knots, the results of testing the color fastness of polyester fabrics are: washing fastness 4-5, sunlight fastness 4-5, dry rubbing fastness 4-5, wet rubbing fastness 4 class.

Embodiment 3

[0021] Embodiment 3: polyester knitted fabric is pre-set through high temperature, and the temperature of each section of the pre-setting setting machine is set as: 190 ℃ × 2, 205 ℃ × 5, 200 ℃, the setting speed is 45m / min, and the dyeing temperature is heated up at 3 ℃ / min at normal temperature to 80°C, then raise the temperature to 132°C at 1°C / min, keep warm for 50 minutes, then drop to 80°C at 2°C / min, add acid reducing agent 5g / l to reduce and wash for 15 minutes, wash with water and set the shape with a damp cloth at 130°C °C×6 knots. The results of testing the color fastness of polyester fabrics are: washing fastness 4-5 grades, sunlight fastness 4-5 grades, dry rubbing fastness 4-5 grades, wet rubbing fastness 4-5 grades.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com