Modified high-effective flue gas heat exchange device

A flue gas heat exchange and improved technology, which can be used in heat exchanger types, direct contact heat exchangers, and greenhouse gas reduction, etc., can solve the problems of low heat exchange efficiency, easy blockage, and large investment in heat exchange devices. , to achieve high heat exchange efficiency, reduce energy consumption, reduce equipment size and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

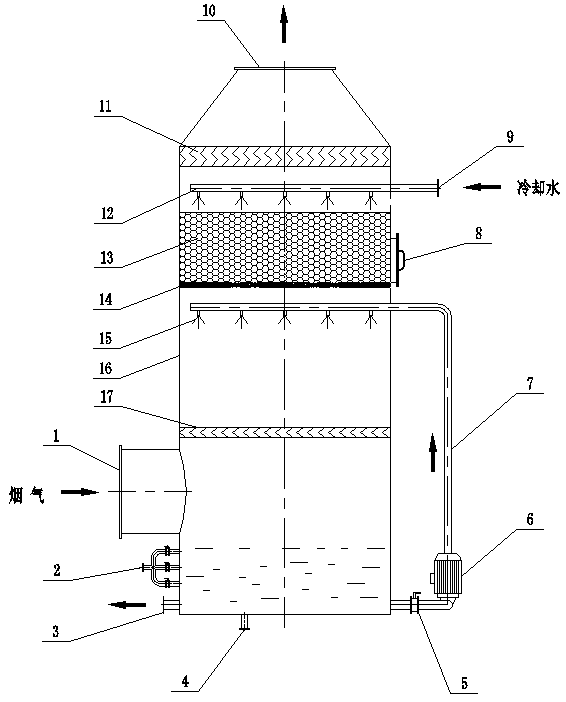

[0015] The invention provides an improved high-efficiency flue gas heat exchange device, which includes a flue gas inlet (1), an overflow port (2), a cooling water outlet (3), a sewage outlet (4), and a stop valve (5) , internal circulation pump (6), inspection port (8), cooling water inlet (9), flue gas outlet (10), demisting device (11), water distributor (12), packing (13), water collecting device (14), spraying device (15), uniform distribution device (17) and other components.

[0016] It is characterized in that: flue gas from coal-fired boilers or gas-fired boilers enters the device through the flue gas inlet (1), and the flue gas is evenly distributed in the flow field through the action of the uniform distribution device (15), firstly with the spray device (14) The sprayed atomized liquid droplets carry out the first direct contact heat exchange. After cooling down, the flue gas conducts a second contact heat exchange with the night film water in the filler (13), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com