A high-efficiency closed-circuit cooling tower capable of automatic descaling

A closed cooling tower, automatic descaling technology, applied in the direction of cleaning heat transfer devices, fixed conduit components, lighting and heating equipment, etc. Reduce the cooling tower treatment effect and other problems to achieve the effect of improving work efficiency and ensuring heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

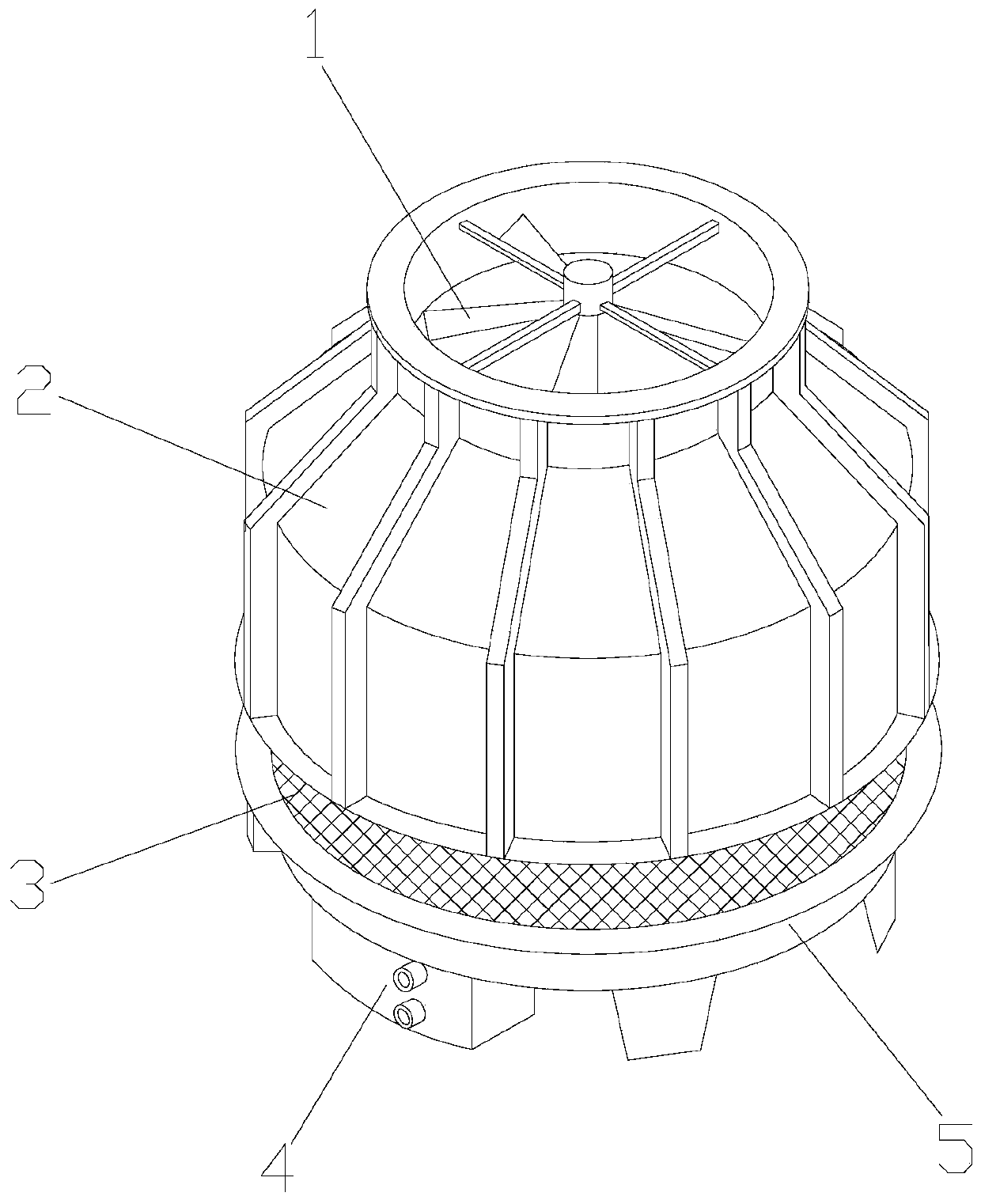

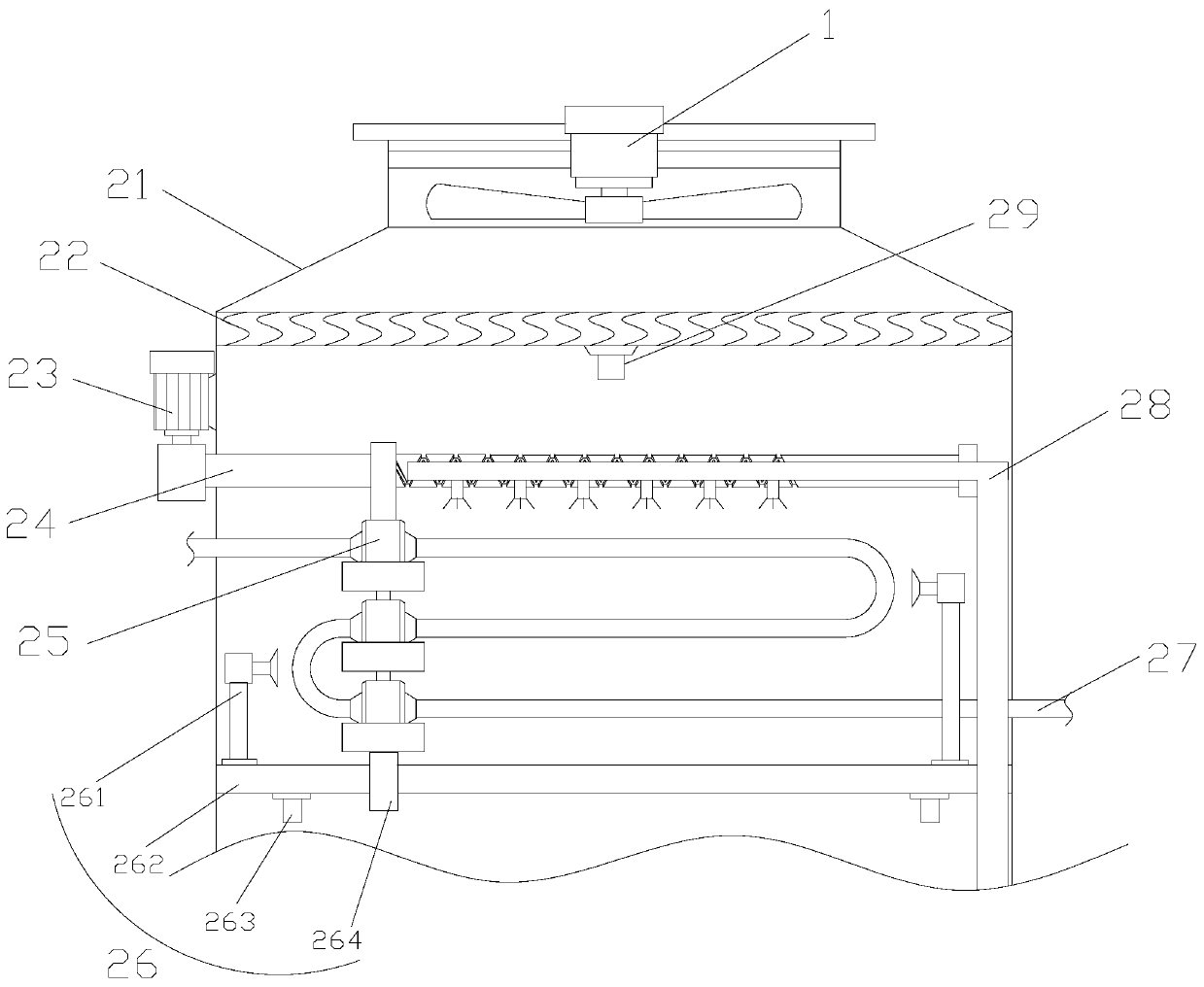

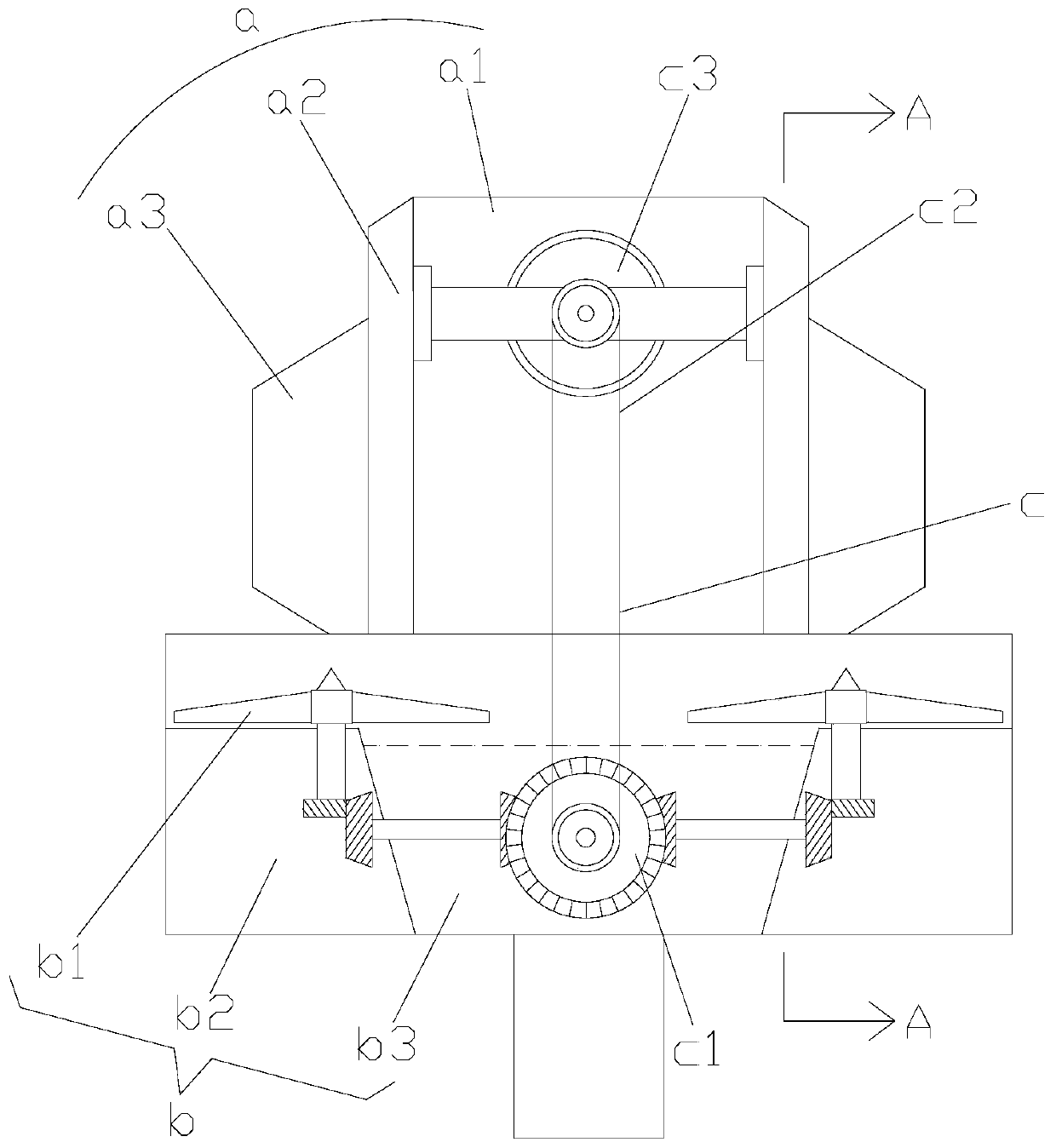

[0028] see Figure 1-Figure 2, the present invention provides a high-efficiency closed cooling tower capable of automatic descaling. It is a cylindrical structure and is horizontally fixed on the ground by bolts. The spray liquid connection pipe 4 is installed on the front of the support base 5 and is integrated with the support base 5. The main body of the cooling tower 2 is welded above the support base 5. The air filter 3 is installed between the cooling tower main body 2 and the support base 5, the heat dissipation fan 1 is welded on the top of the cooling tower main body 2, and the cooling tower main body 2 is driven by the cooling tower protective cover 21, the dehydrator 22, Motor 23, reciprocating screw rod 24, heat exchange tube cleaning device 25, jet descaling device 26, heat exchange tube main body 27, spray pipe 28, dirt detection sensor 29, the cooling tower protection cover 21 is a hollow cylinder and a round platform The combined shape and the bottom are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com