Novel D type microstructure-based optical fiber sensor and preparation method thereof

A microstructure optical fiber and sensor technology, applied in the field of optical sensing, can solve the problems that the air holes are not easy to be coated and filled with analytes, and the optical fiber cannot be uniformly coated, so as to improve stability and sensitivity, facilitate filling, and improve sensitivity and precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

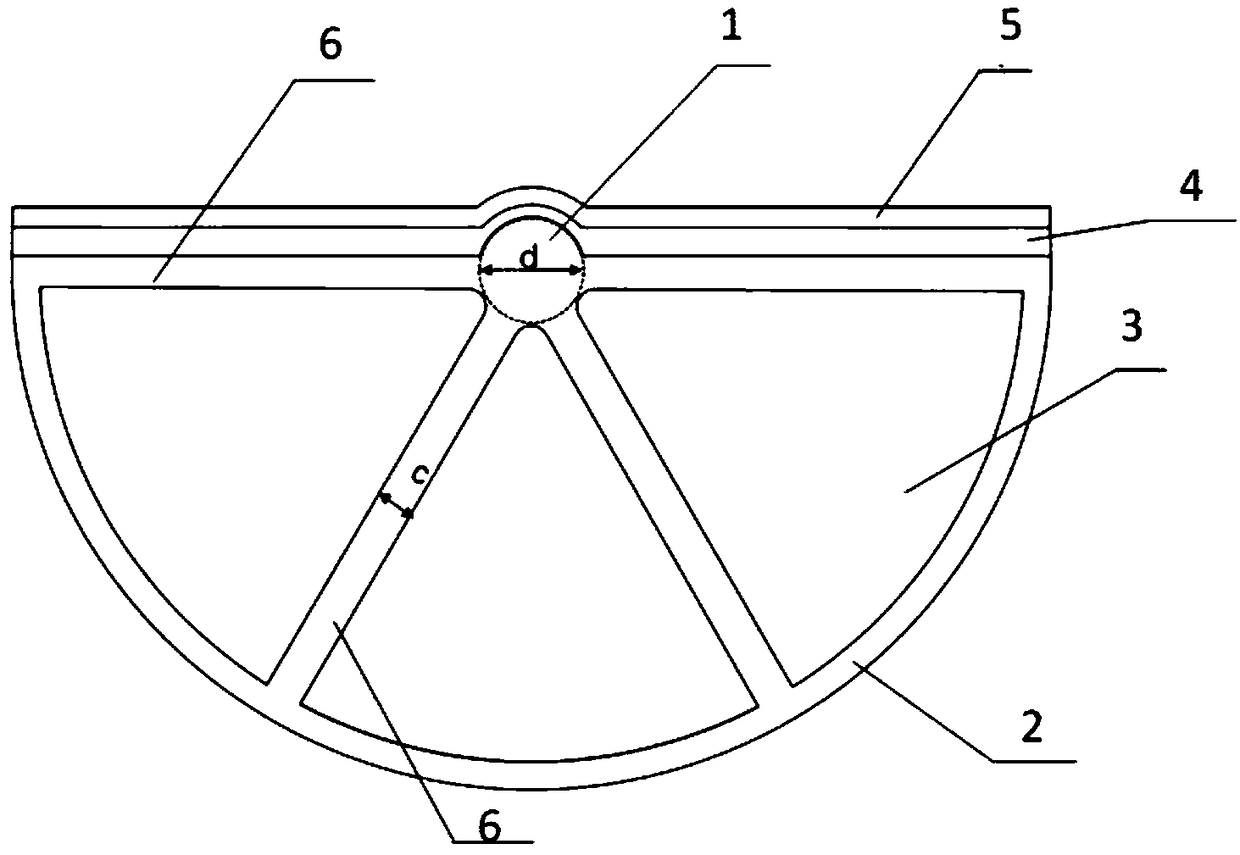

[0038] Such as figure 1 As shown, a new D-type microstructure optical fiber sensor is based on D-type LMR microstructure fiber. The outer diameter of the D-type LMR microstructure fiber is 125 μm, and the material is fused silica. It adopts a core-clad structure, including a complete fiber Core 1, semicircular cladding 2 and 3 evenly distributed air holes 3 with fan-shaped cross-sections arranged between the core 1 and cladding 2, the diameter d of the core 1 is 15 μm, and the air holes 3 is provided with a boundary isolation layer 6, and the thickness c of the boundary isolation layer 6 is 2 μm. Wherein the two boundary isolation layers 6 take the fiber core 1 as the center of circle to form the diameter of the LMR microstructure optical fiber, that is, the complete smooth plane formed by the fiber core 1 and the boundary isolation layers 6 on both sides, which is coated with TiO 2 Thin film layer 4, TiO 2 Thin film layer thickness is 100nm, TiO 2 The thin film layer is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com