Flexible piezoelectric three-dimensional tactile sensor array and preparation method thereof

A tactile sensor, flexible piezoelectric technology, applied in the field of tactile sensors, can solve the problems that flexible tactile sensors cannot combine high flexibility and high sensitivity, and achieve high sensitivity and high flexibility, increase gain, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

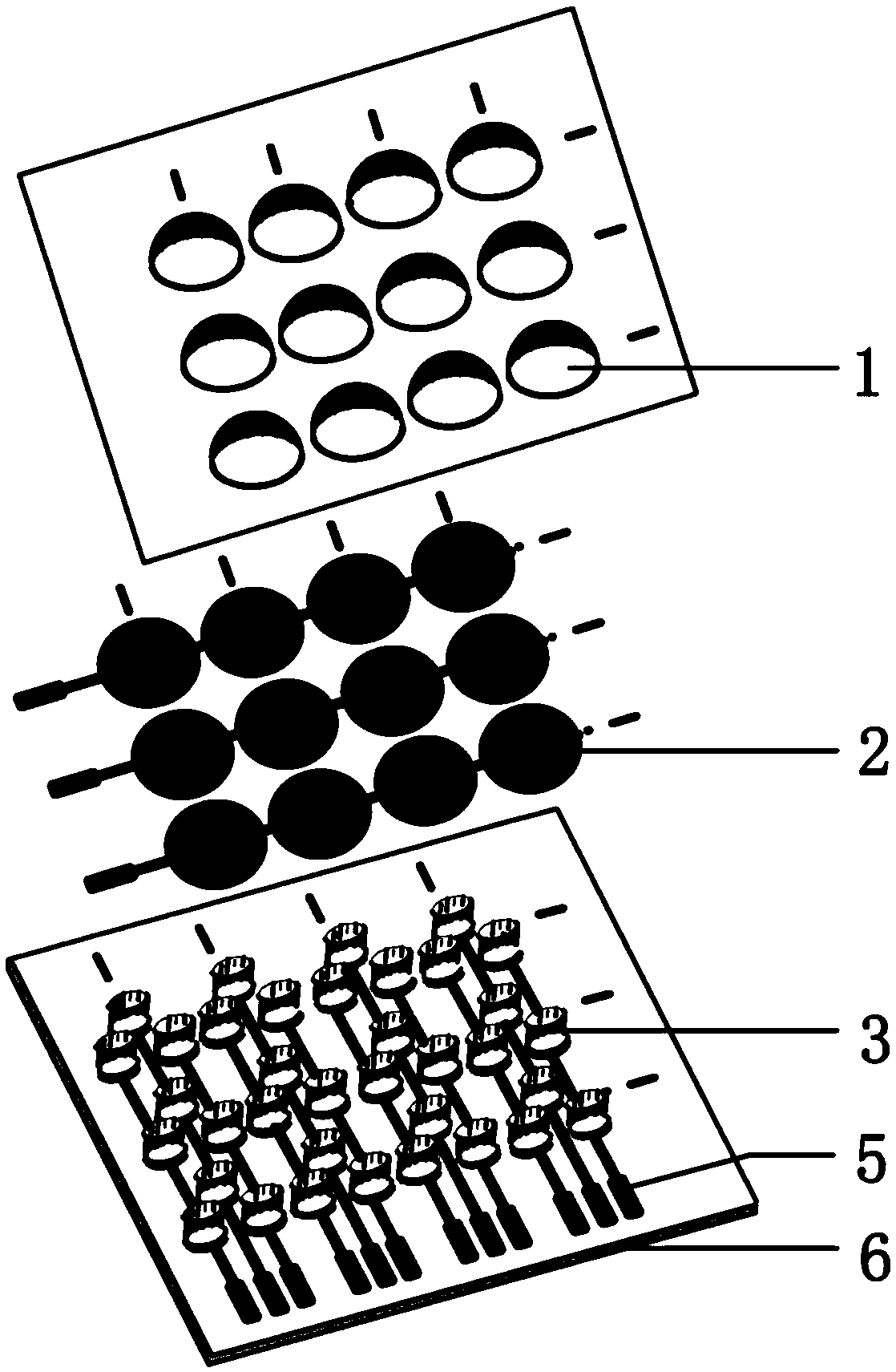

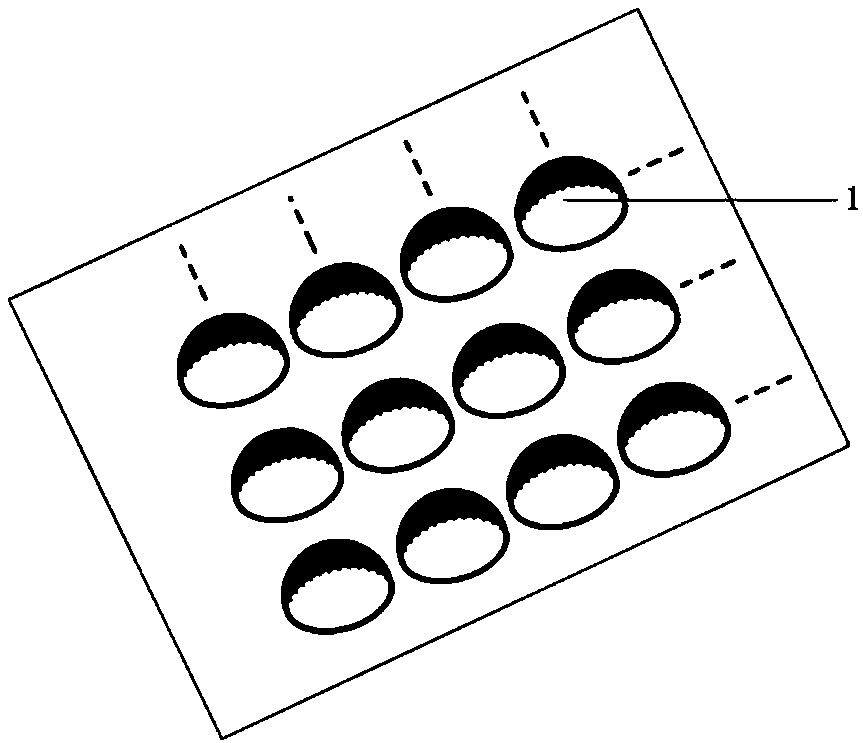

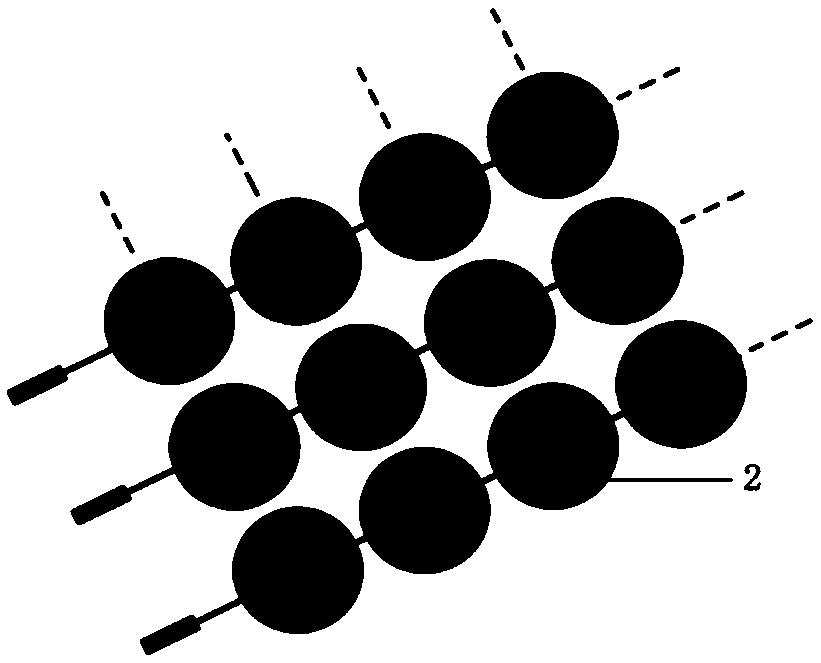

[0040] Such as figure 1As shown, a flexible piezoelectric three-dimensional tactile sensor array, its structure includes: PDMS hemispherical convex layer 1, upper electrode layer 2, nanostructure piezoelectric film layer 3, lower electrode layer connected sequentially from top to bottom 5. And the base layer 6 of the flexible printed circuit board; the three-dimensional touch sensor array is composed of M×N three-dimensional touch sensor units separated from each other, and each three-dimensional touch sensor unit also includes a piezoelectric sensitive capacitor for insulation isolation polyimide flexible membrane 4, such as Figure 6 shown;

[0041] In this embodiment, M=3, N=4, that is, 12 sensor units in total of 3×4; the PDMS hemispherical raised layer 1 is a patterned PDMS film with a PDMS hemisphere arranged in 3×4 on the surface, And covered on the upper electrode pattern arranged in 3×4, the planar structures of the PDMS hemispherical raised layer 1 and the upper el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com