Measuring system and measuring method for centroid

A measurement system, measurement method technology, applied in the field of precision mechanical engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Below in conjunction with accompanying drawing, measuring system and measuring method of the present invention are further introduced:

[0081] Measuring system composition

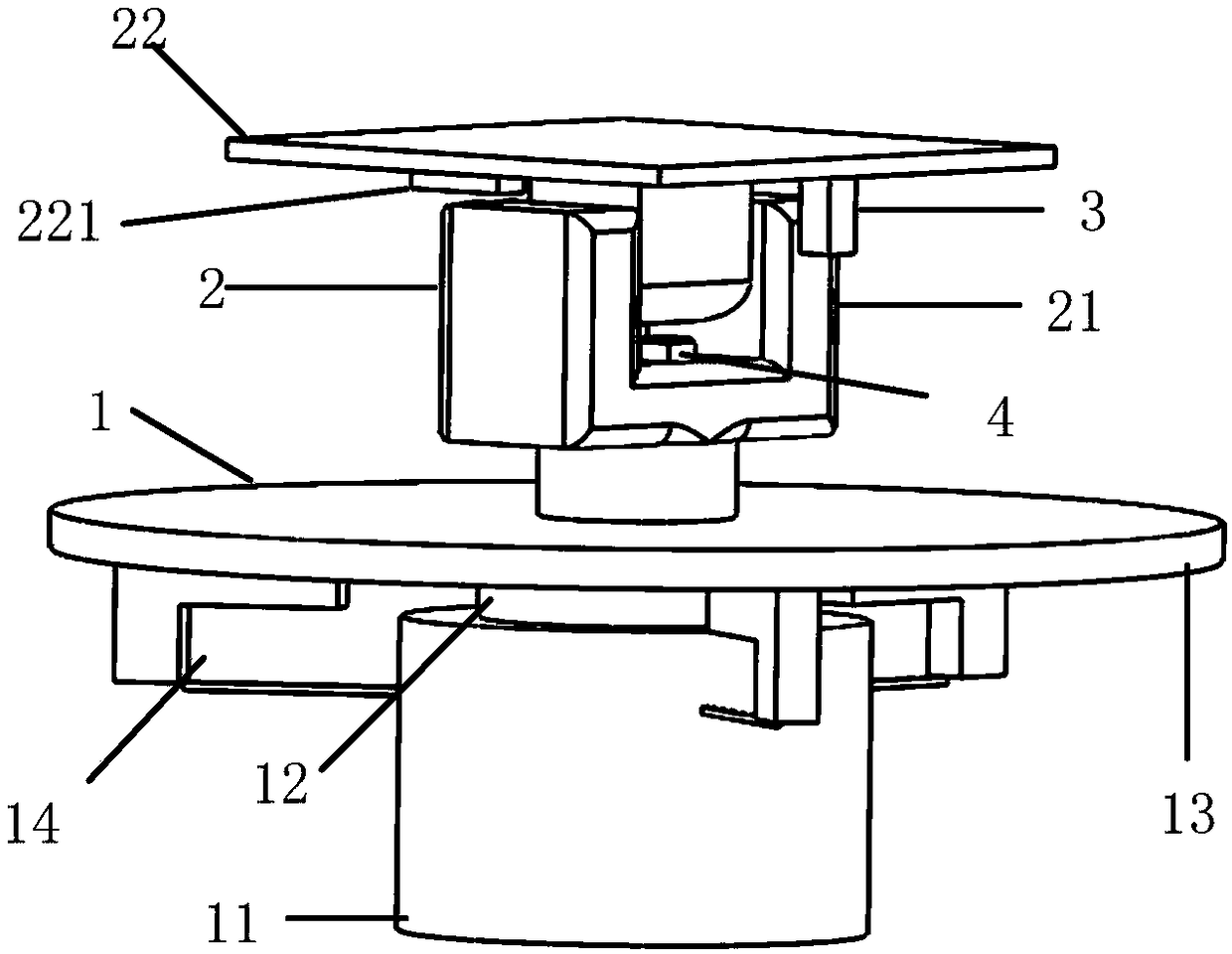

[0082] Such as figure 1 As shown, a center of mass measurement system includes a three-axis air buoyancy moment test bench 1, a two-dimensional rotating mechanism 2, a first center of mass adjustment mechanism 3 and a second center of mass adjustment mechanism 4;

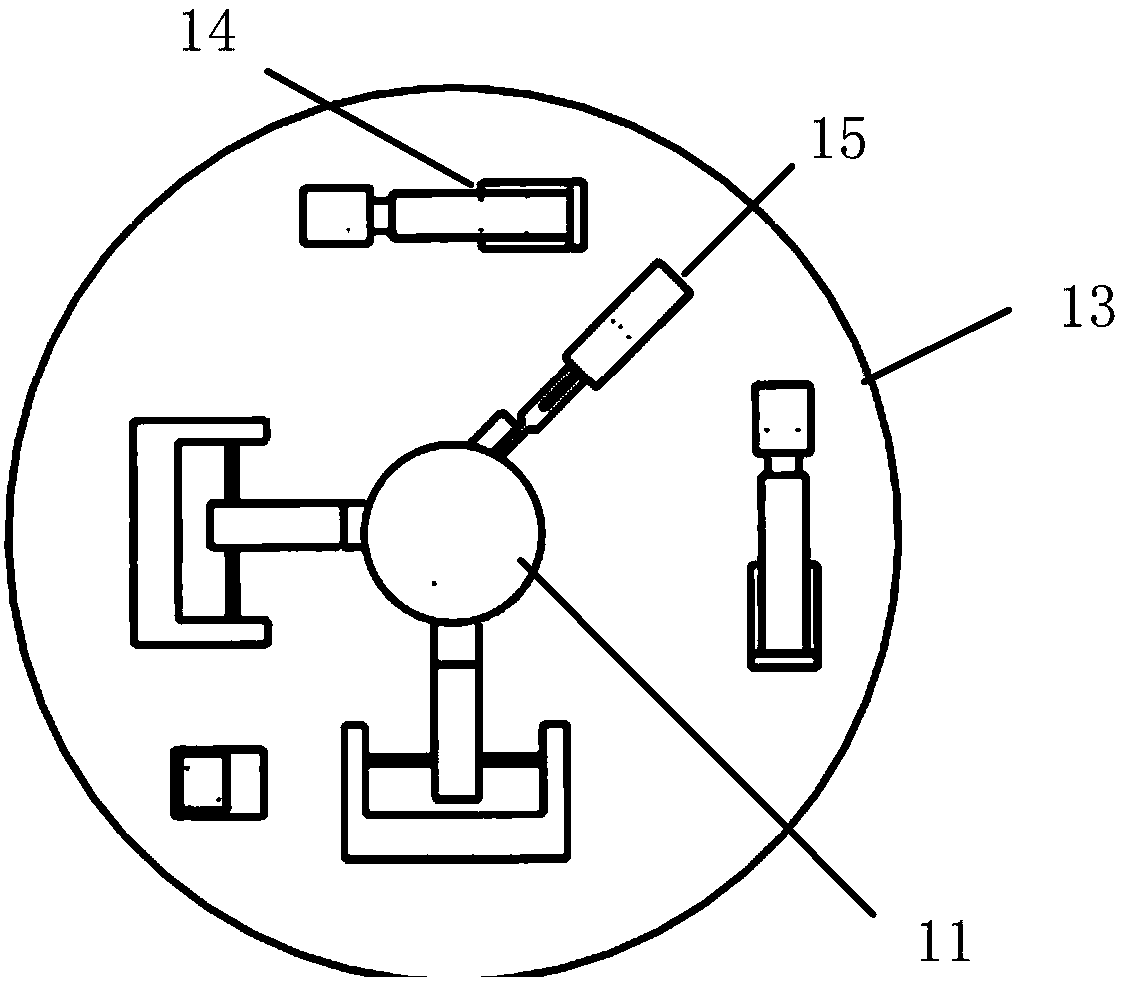

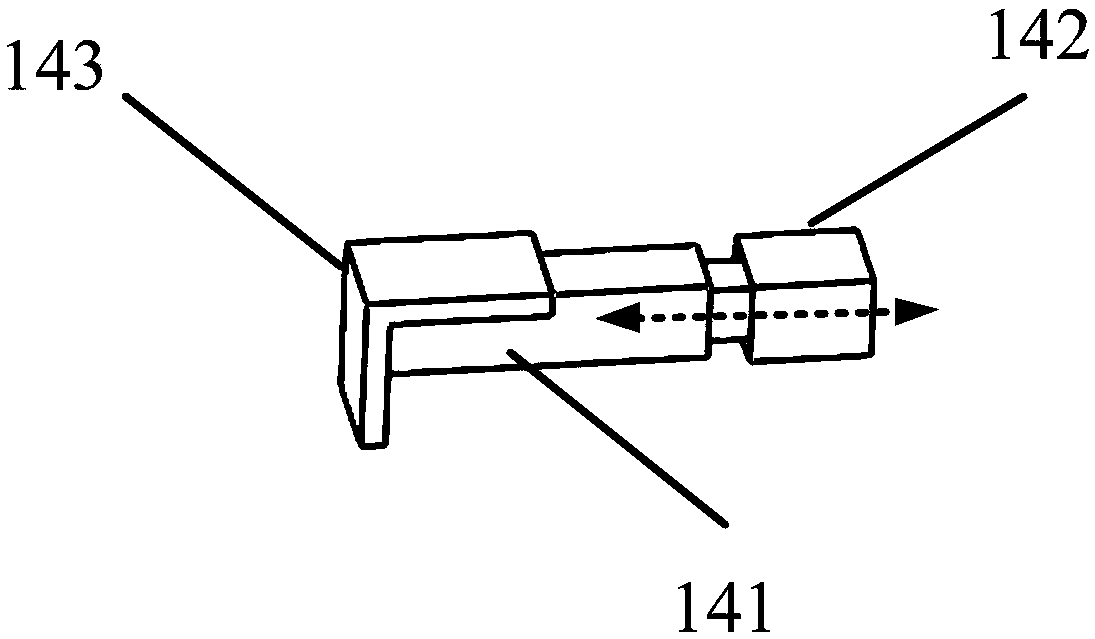

[0083] The three-axis air bearing moment test bench 1 includes a support 11, an air bearing 12, an air bearing platform 13, a gravity balance adjustment mechanism 14, and a force sensor assembly 15; the air bearing 12 is coaxially installed in the support 11, The air bearing 12 is equipped with an air floating platform table 13; the lower surface of the air floating platform table 13 is equipped with a gravity balance adjustment mechanism 14 for adjusting the three directions of X, Y, and Z, and for measuring the three directions of X, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com