A machine learning recognition and process parameter optimization method for abrasive belt abrasion

A process parameter optimization and machine learning technology, applied in character and pattern recognition, instruments, biological models, etc., can solve problems such as the inapplicability of abrasive belts, and achieve the effect of convenient measurement, good measurement accuracy, and good prediction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

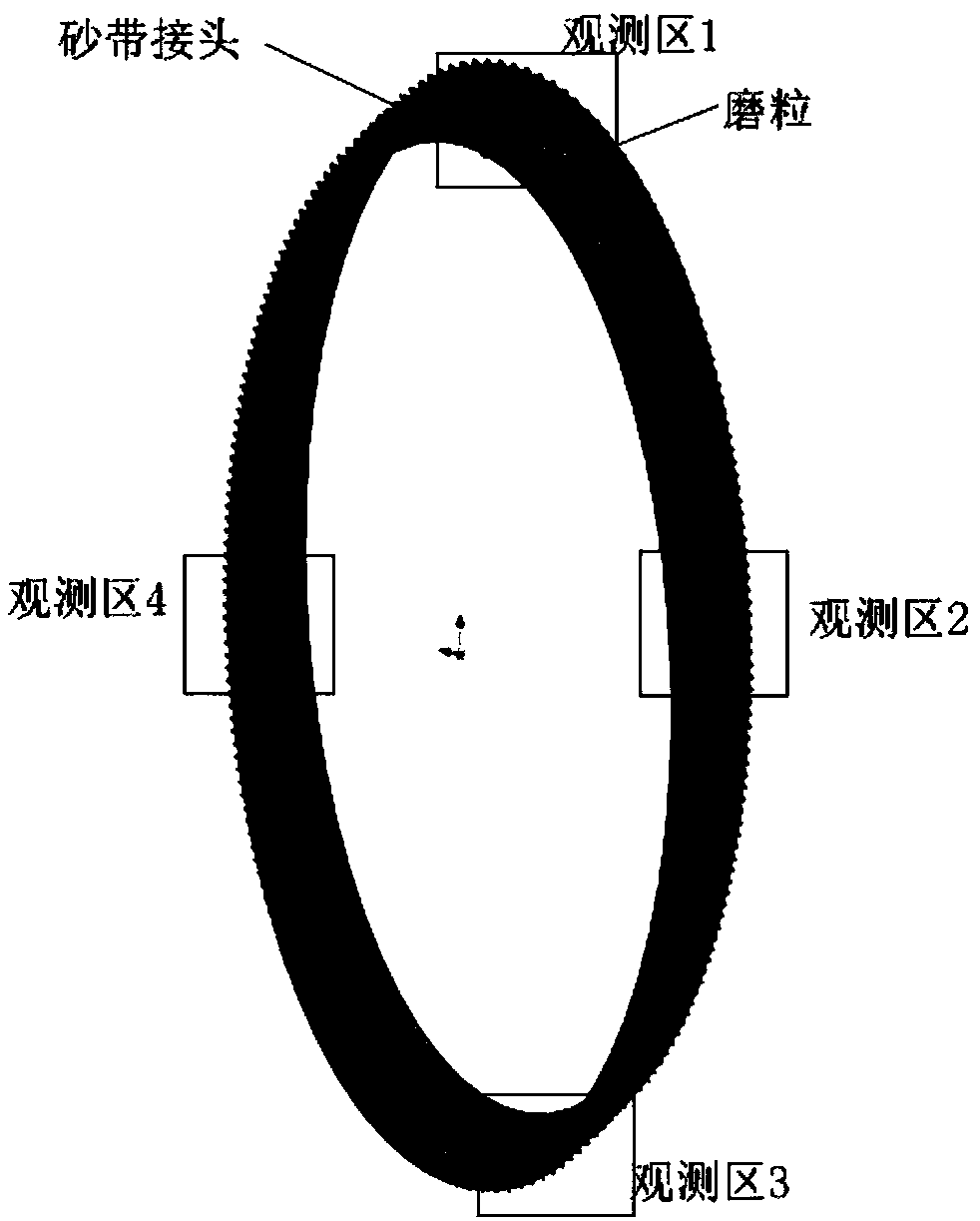

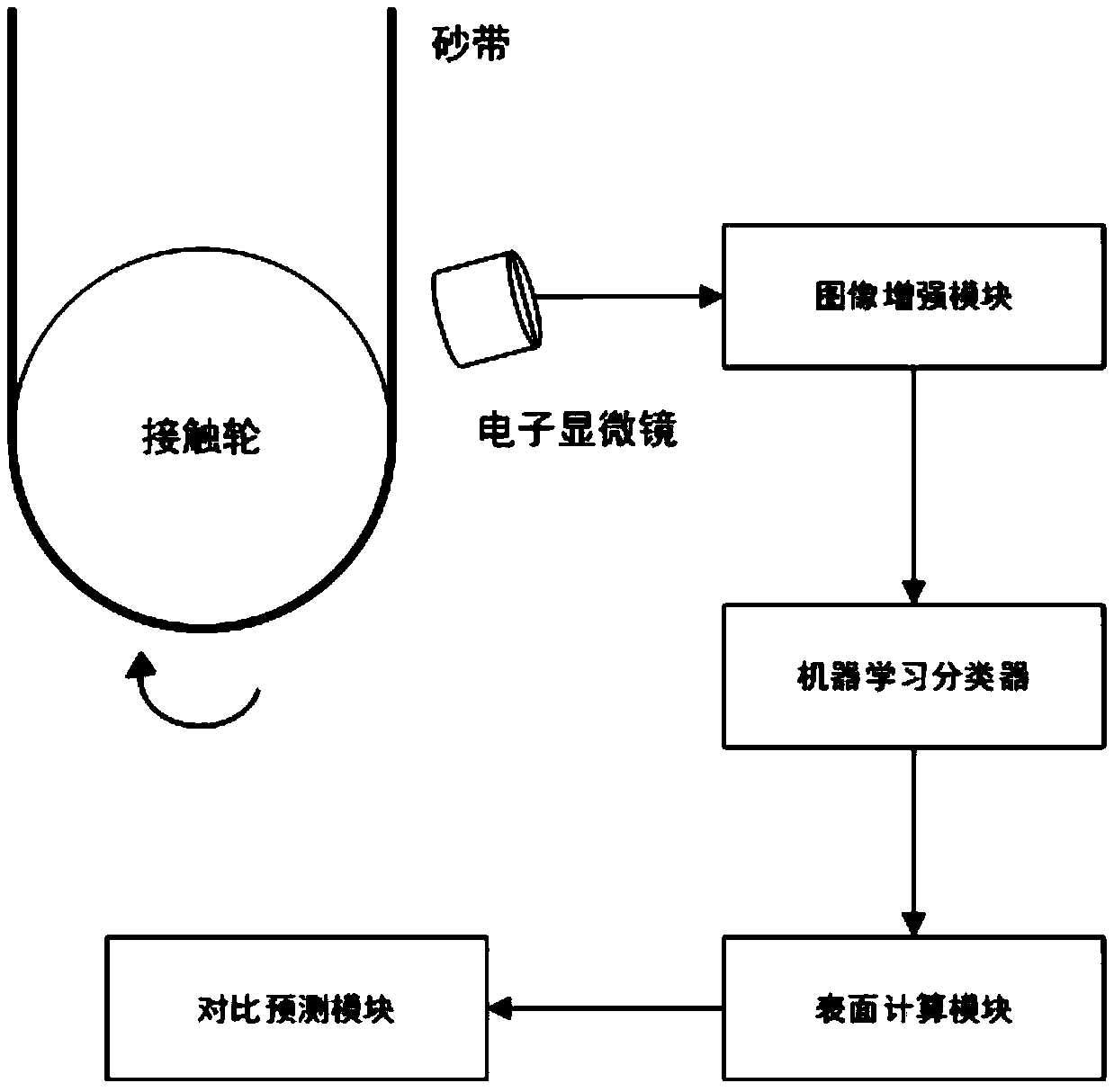

[0047] The present invention designs a method for machine learning recognition and process parameter optimization of abrasive belt wear. The method of the present invention is executed through image recognition technology, and the image of the worn area and the image of the unworn area in the image are obtained by this method. Calculate the edges of different regions and use color information to distinguish different regions. And use the new particle swarm optimization algorithm to optimize the experimental parameters.

[0048] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

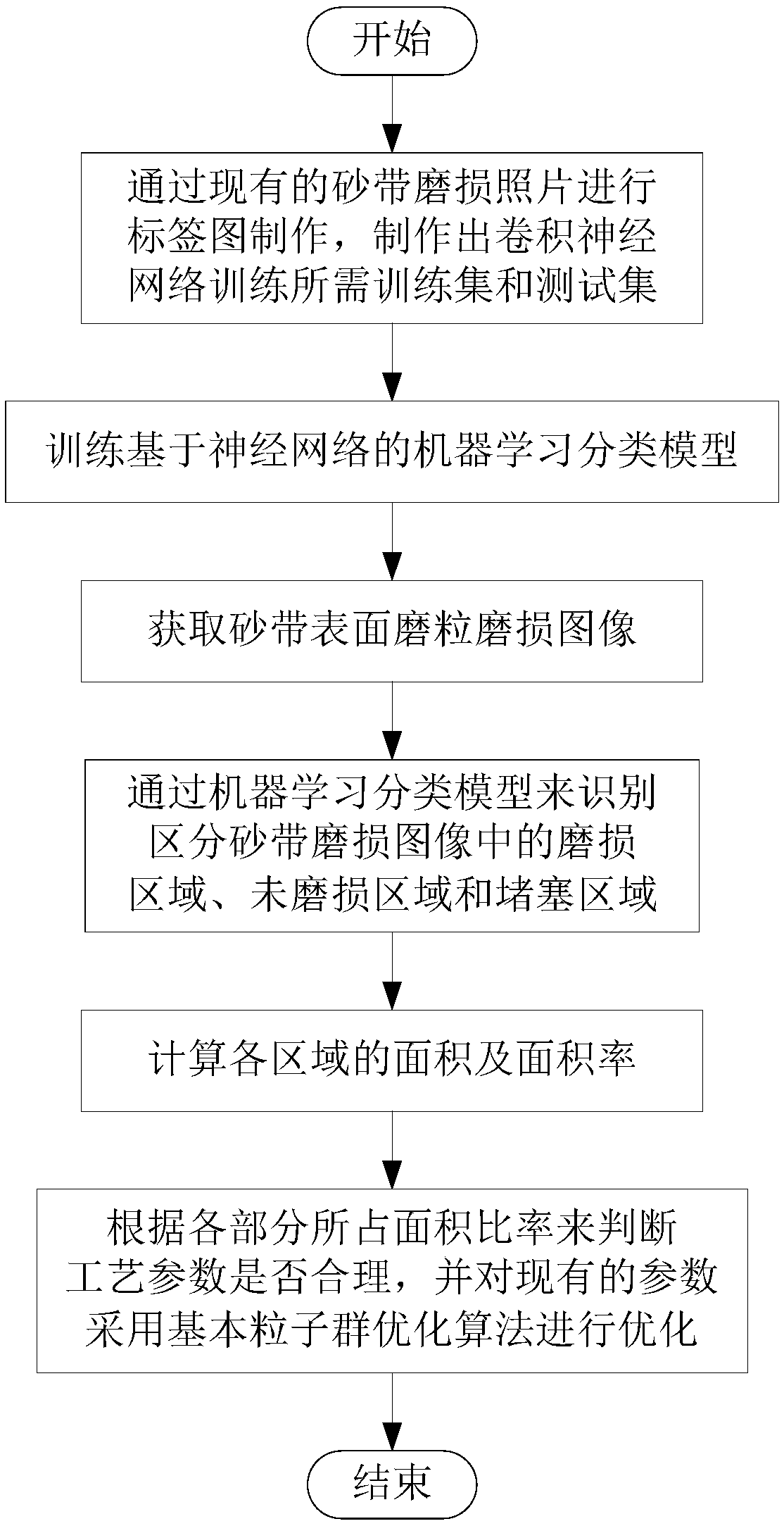

[0049] like figure 1 As shown, the machine learning identification and process parameter optimization method of abrasive belt wear of the present invention comprises the following steps:

[0050] S1. Make a label map through the existing photos of abrasive belt wear, and then output an index map to make a training set and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com