Three-dimensional packaging method with surface protection effect

A packaging method, a three-dimensional technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as chip packaging failure, molding module failure, surface coating peeling off, etc., to achieve good insulation isolation, compact internal structure, The effect of protective metal plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

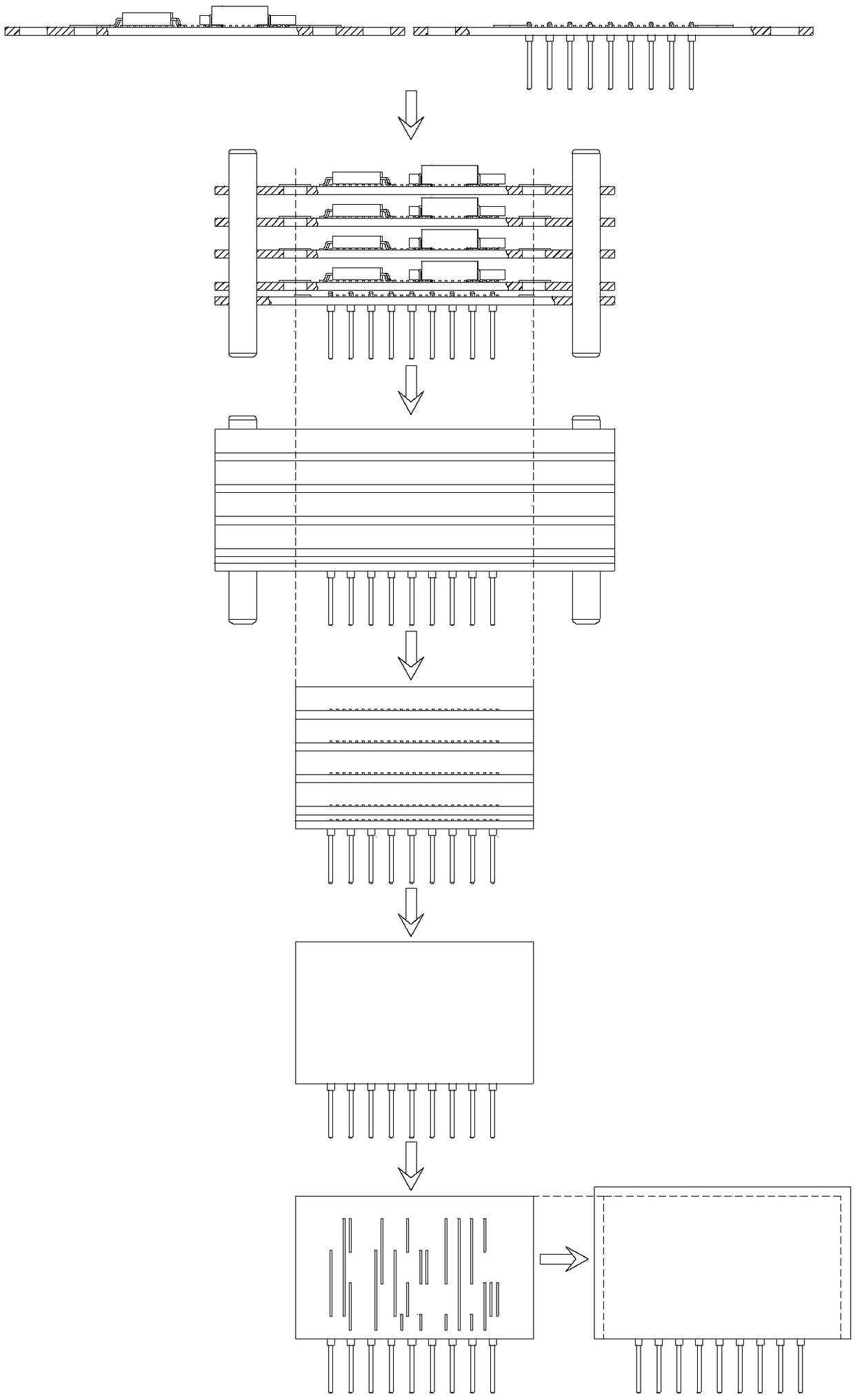

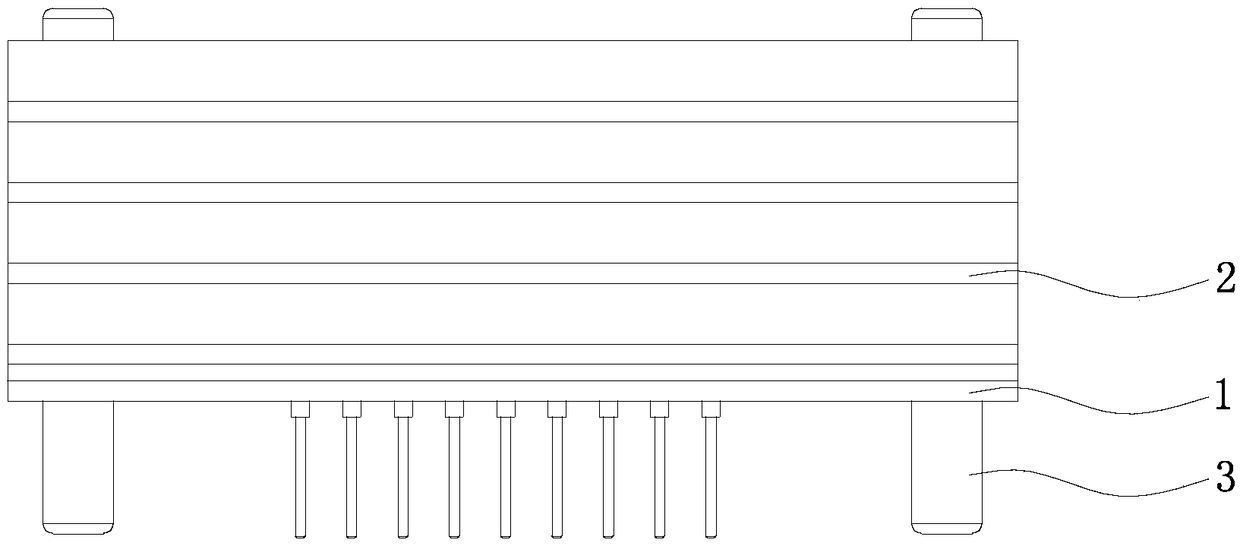

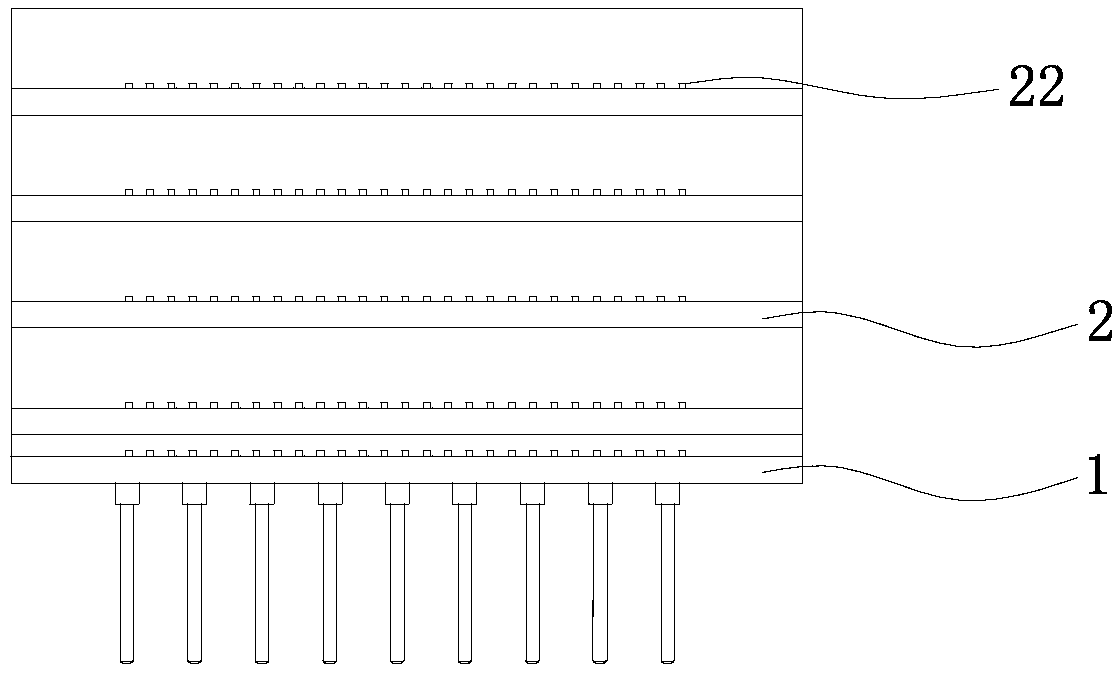

[0028] Such as Figure 1 to Figure 5 As shown, a vertical interconnection method for three-dimensional packaging includes the following steps:

[0029] Step a, electrical installation, the PCB board is divided into the middle part and the outside along the radial direction, the component 21 is assembled to the middle part of the PCB board, the outside of the PCB board is milled and drilled to form a slot 23 passing through the upper and lower ends, and the upper end of the slot 23 is assembled with an electrical connection component 21 The lead bridge 22, the positioning hole is milled and drilled on the PCB board to obtain the laminated board 2; the pins 11 are clamped on the jig, and one end of several pins 11 is connected through resin potting to obtain a socket with several pins 11 The base plate 1, the lead bridge 22 electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com