Flame retardant grease composition

A grease composition and flame retardancy technology, applied in the directions of lubricating compositions, gear lubrication/cooling, mechanical equipment, etc., can solve the problems of undocumented flame retardancy, fire resistance, etc. Excellent rust resistance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

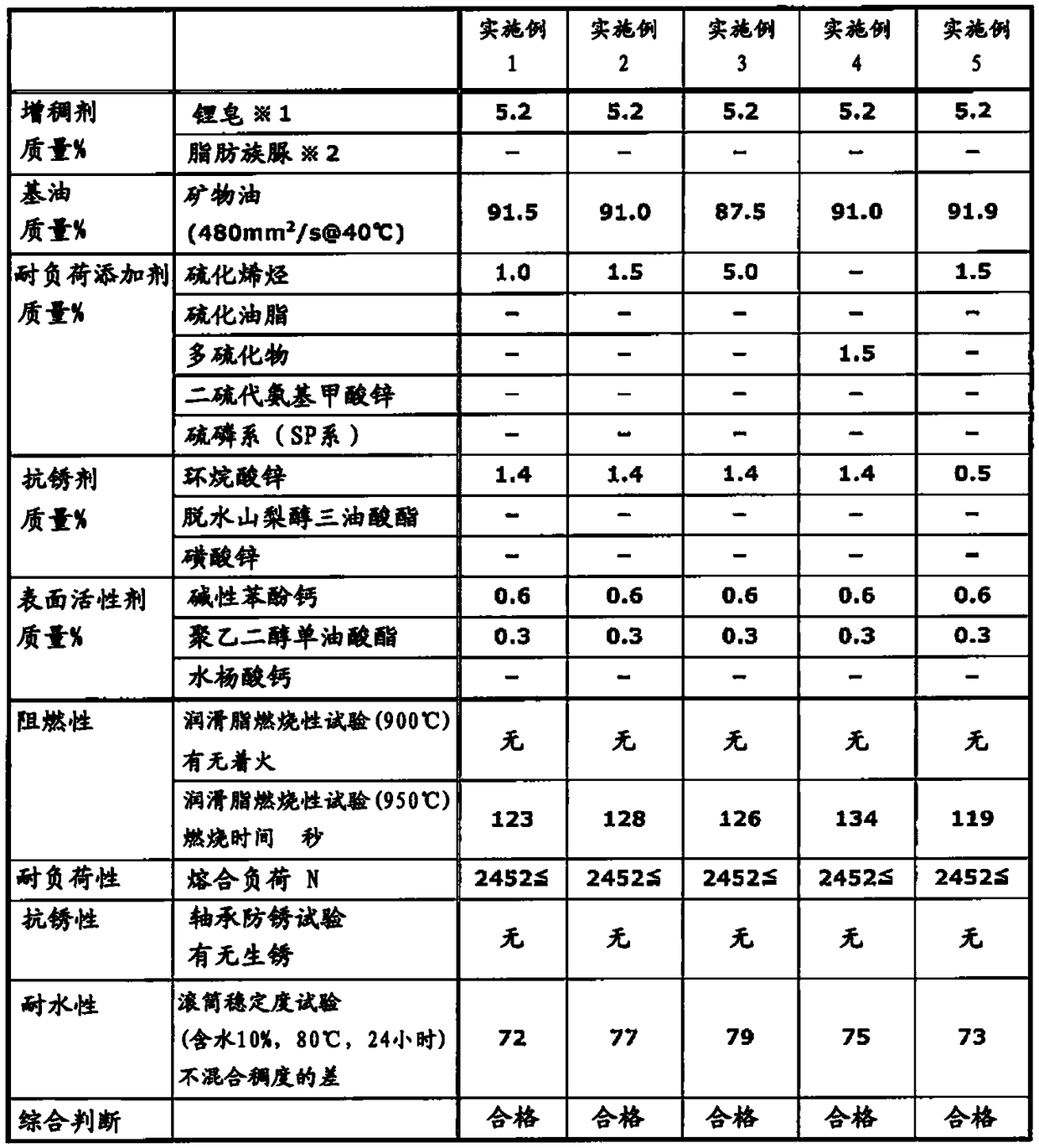

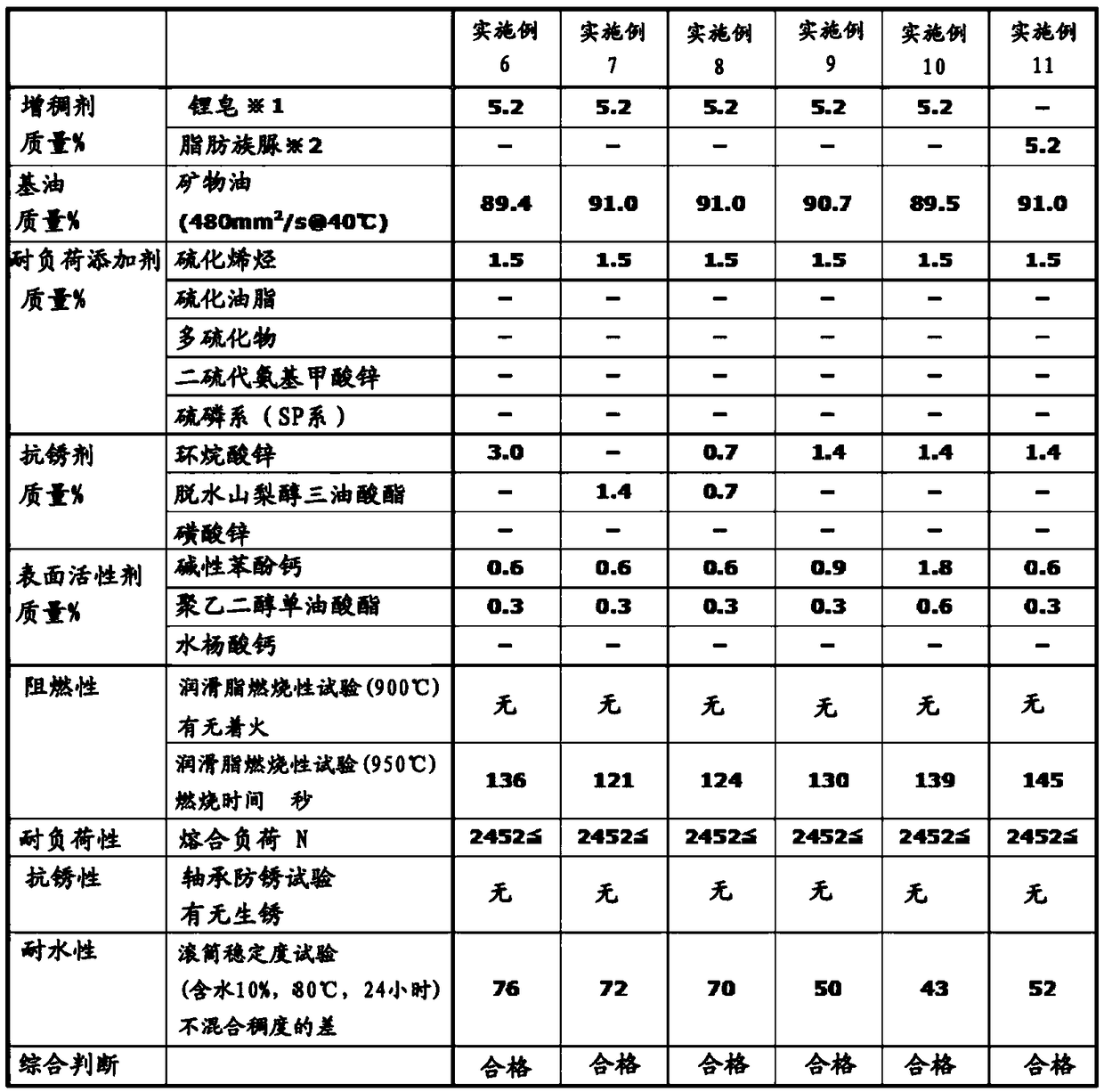

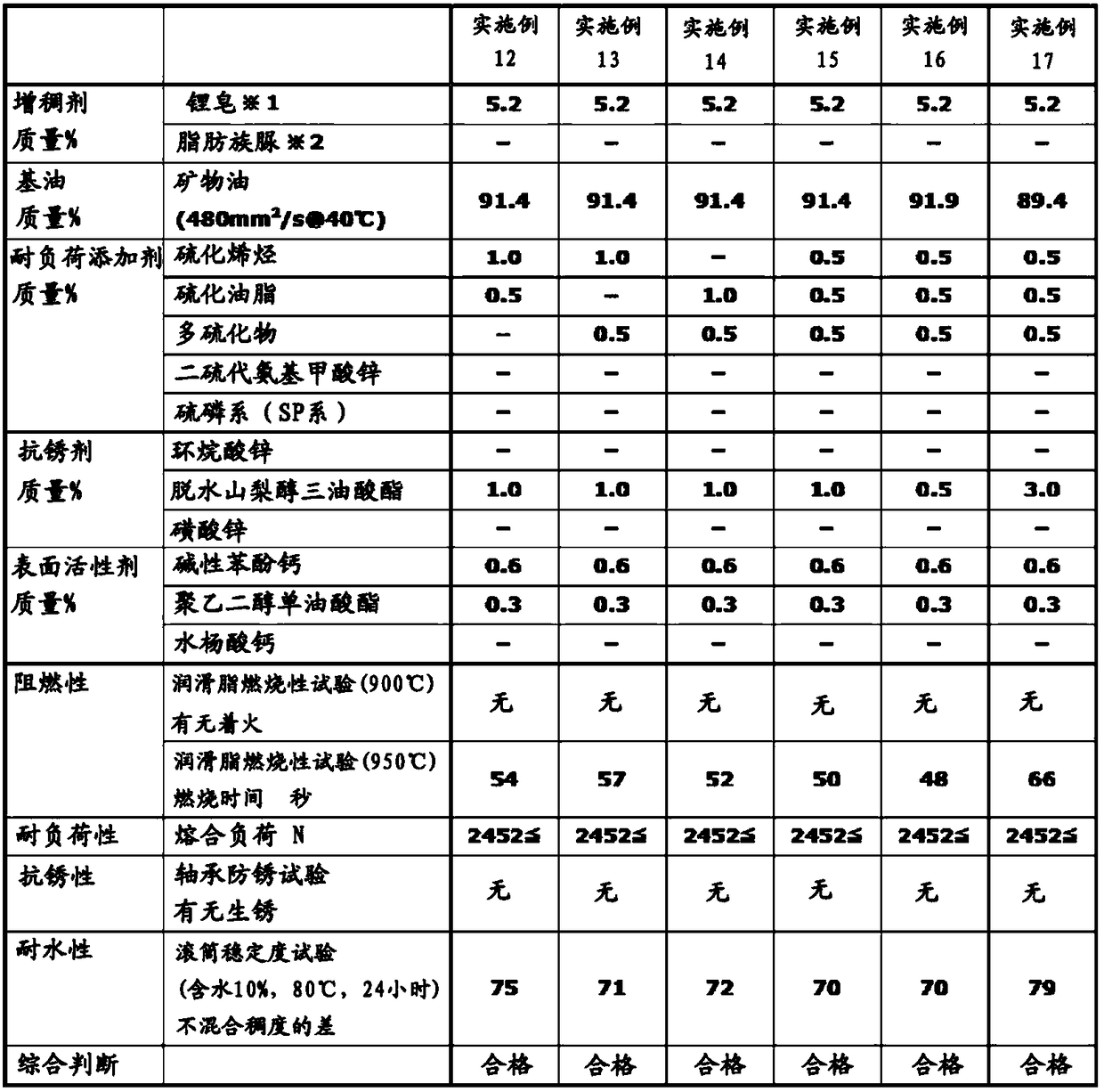

[0082] The thickeners, base oils, load-resistant additives, rust inhibitors, and surfactants shown in Tables 1 to 5 were prepared in accordance with the amounts (mass%) shown in the tables to prepare grease compositions of the Examples and Comparative Examples . These grease compositions were used as test samples to evaluate flame retardancy, load resistance, rust resistance, and water resistance. It should be noted that the kinematic viscosity at 40°C of the base oil is measured in accordance with JIS K2283.

[0083] 1. Flame retardancy evaluation

[0084] The flame retardancy (ignition temperature and self-extinguishing property) was evaluated by a grease flammability test. In the grease flammability test, 20 g of the grease composition was placed in a cylindrical metal container (ointment kettle) with an inner diameter of 65 mm and a depth of 13 mm, and a steel ball (diameter 19.05) heated to various temperatures (900, 950°C) was placed in it. mm), to determine whether there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com