Tunable and scalable synthesis of hierarchical porous nanocarbon/sulfur composite cathodes

A technology of graded porous and porous carbon, applied in battery electrodes, electrical components, non-aqueous electrolyte batteries, etc., can solve the problems of difficult high rate performance and high power output, low degree of graphitization of CNF, poor electrical conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

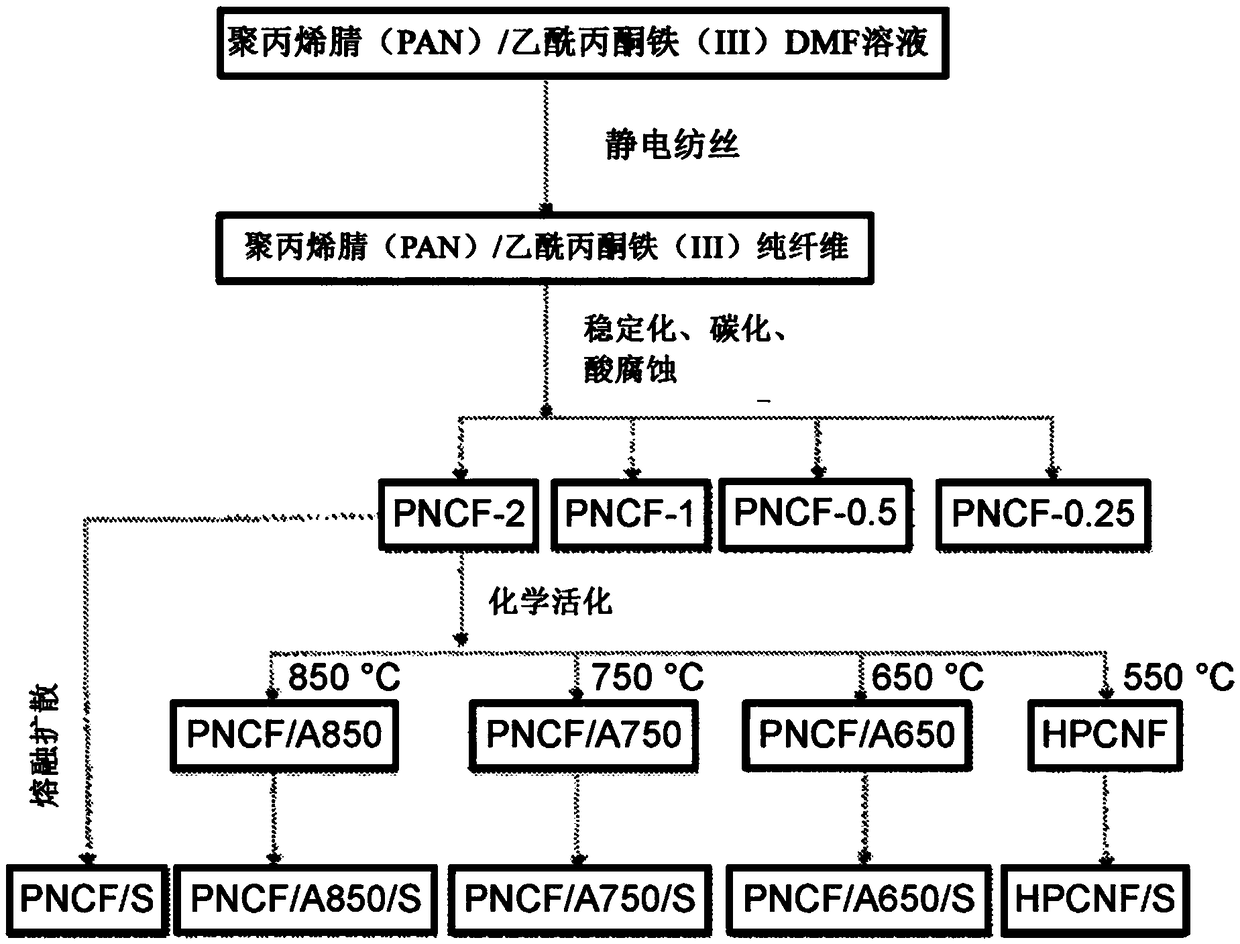

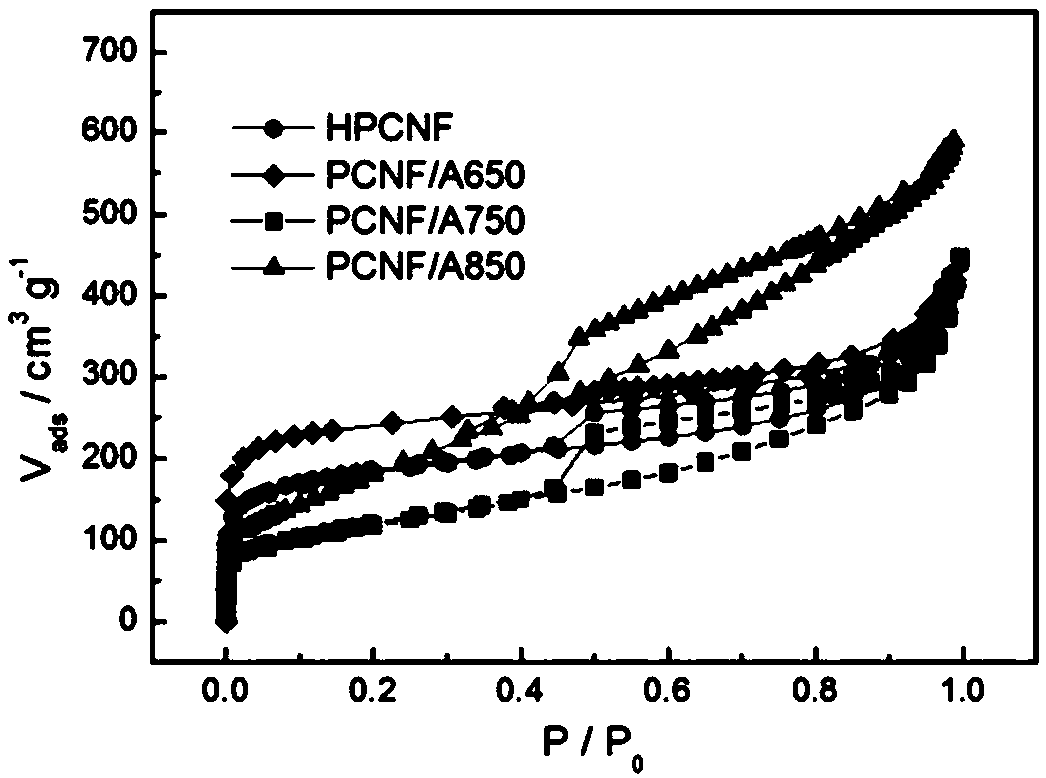

[0023] The hierarchical porous CNF with excellent characteristics is used to prepare advanced porous CNF / sulfur composite cathodes with high rate performance and long cycle life. This CNF / sulfur composite cathode is obtained by controlling the content of the sacrificial agent / catalyst, the conditions of chemical activation, and optimizing the melt-diffusion method for the infiltration of sulfur particles.

[0024] The present invention describes a method for synthesizing HPCNF / S composite materials using the electrospinning method and the melt-diffusion method. It should be noted that the preparation methods of hierarchical porous carbon nanofibers (HPCNF) and hierarchical porous carbon nanofibers / sulfur (HPCNF / S) and porous carbon fiber / sulfur (PCNF / S) composites are quite different. Generally, HPCNF / S composites are formed by adding sulfur to hierarchical porous carbon nanofibers (HPCNF).

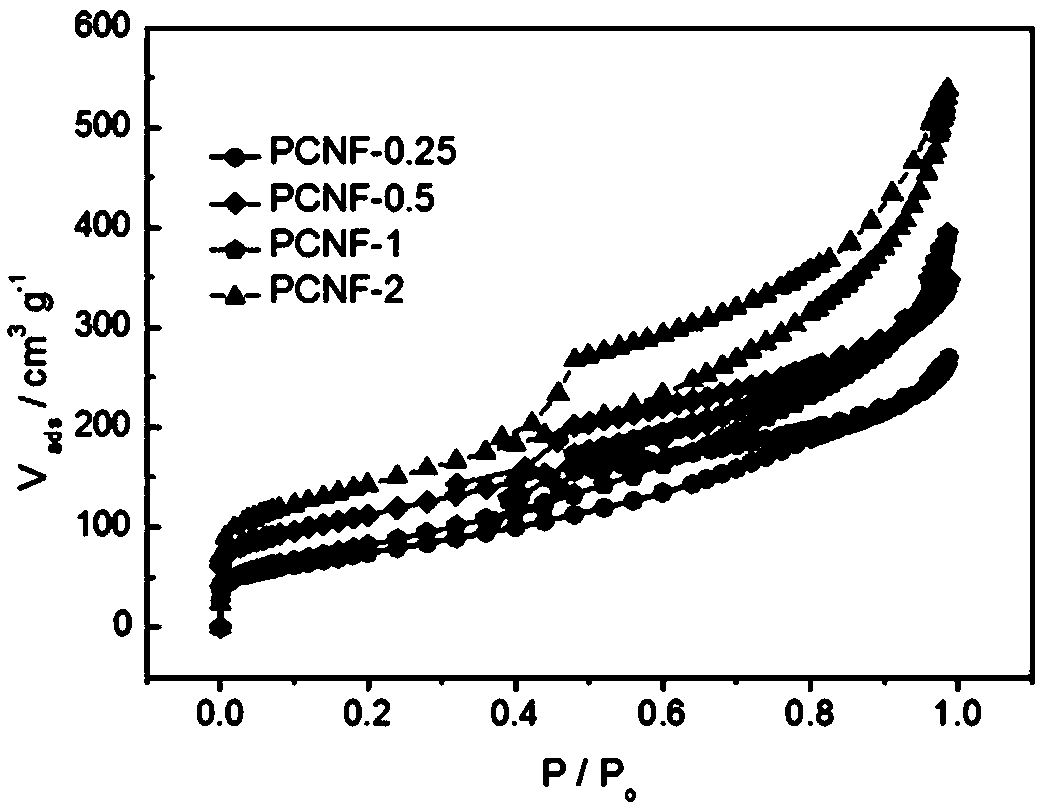

[0025] The HPCNF successfully prepared by electrospinning has a high specific surface are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com