Stainless steel grinding oily waste slag clean resource treatment equipment

A processing equipment and recycling technology, which is applied in the field of stainless steel grinding oily waste slag cleaning and recycling processing equipment, can solve the problems of increased difficulty, a large amount of smoke and dust, and the generation of dioxins, and achieve high production and processing capacity, small footprint, and Effects with fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

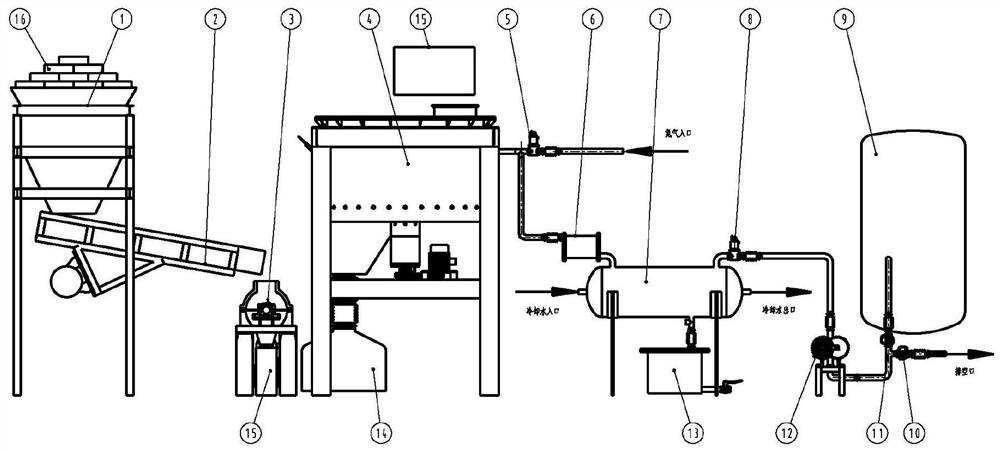

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

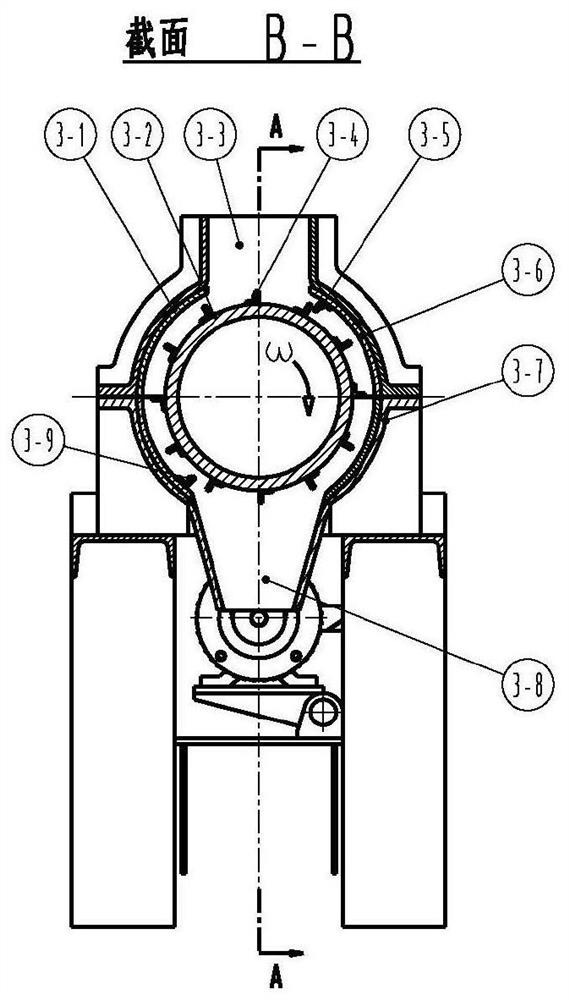

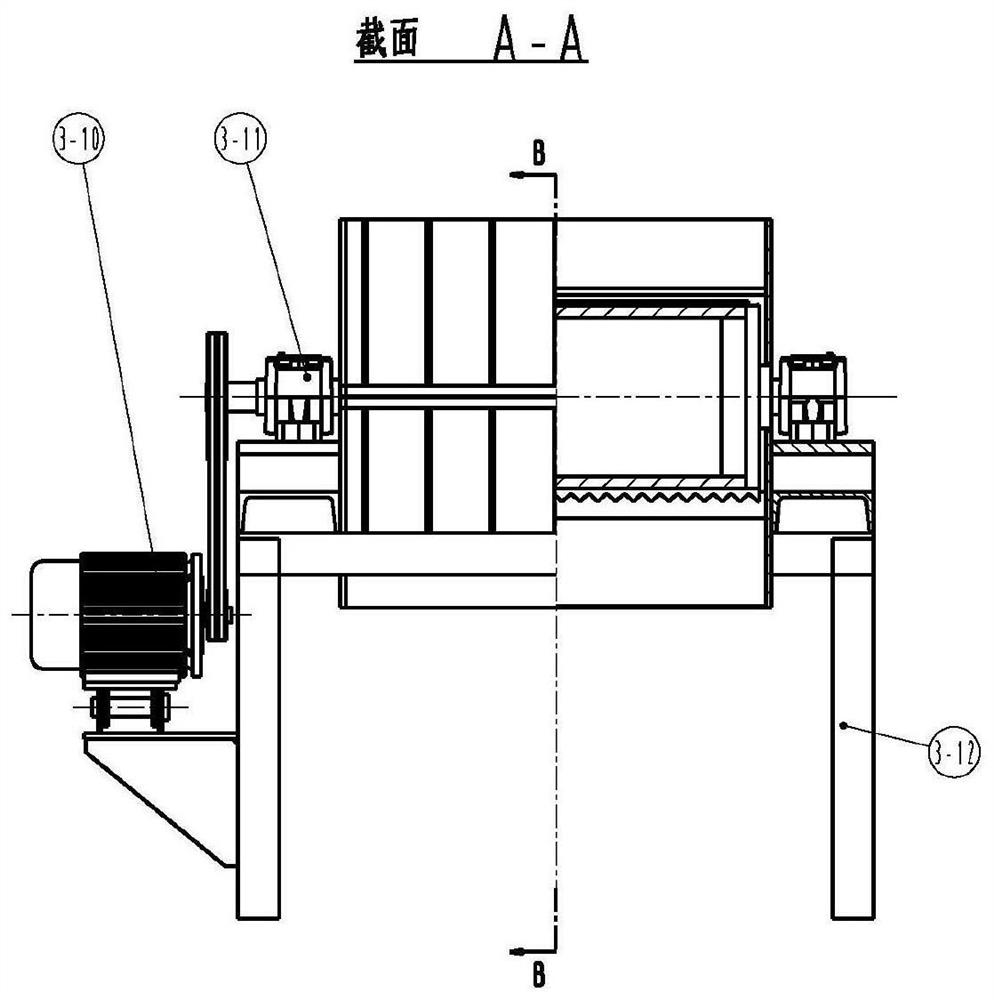

[0029] The use of vacuum distillation to treat stainless steel grinding oily waste residue needs to solve three difficulties: (1) the crushing of the oily residue cake; (2) the separated oil must be pure and pollution-free; (3) the separated residue can be easily removed from the separation tank out. The separated oil and slag are valuable resources, the recovered oil can be reused, and the slag can be used as raw material for steelmaking.

[0030] The invention adopts self-designed slag cake crushing equipment to break the oily slag cake into smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com