Tie for tie separation of tunnel boring machine trolley and battery electric vehicle system and construction method thereof

A technology of battery car and shield machine, which is applied in the direction of track, movable track, laying track, etc., can solve the problems of low track height, easy de-slotting of track slot, derailment of battery car, etc. Remove the shift effect with ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

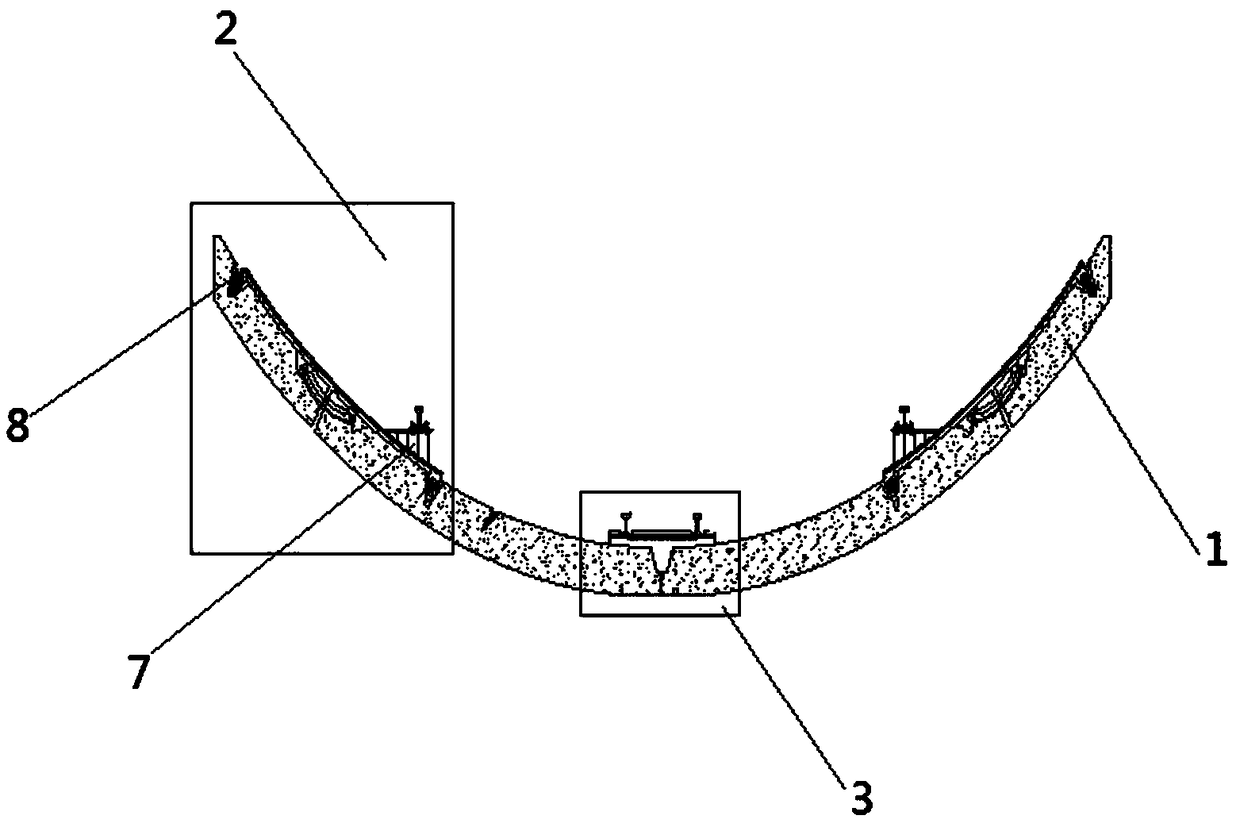

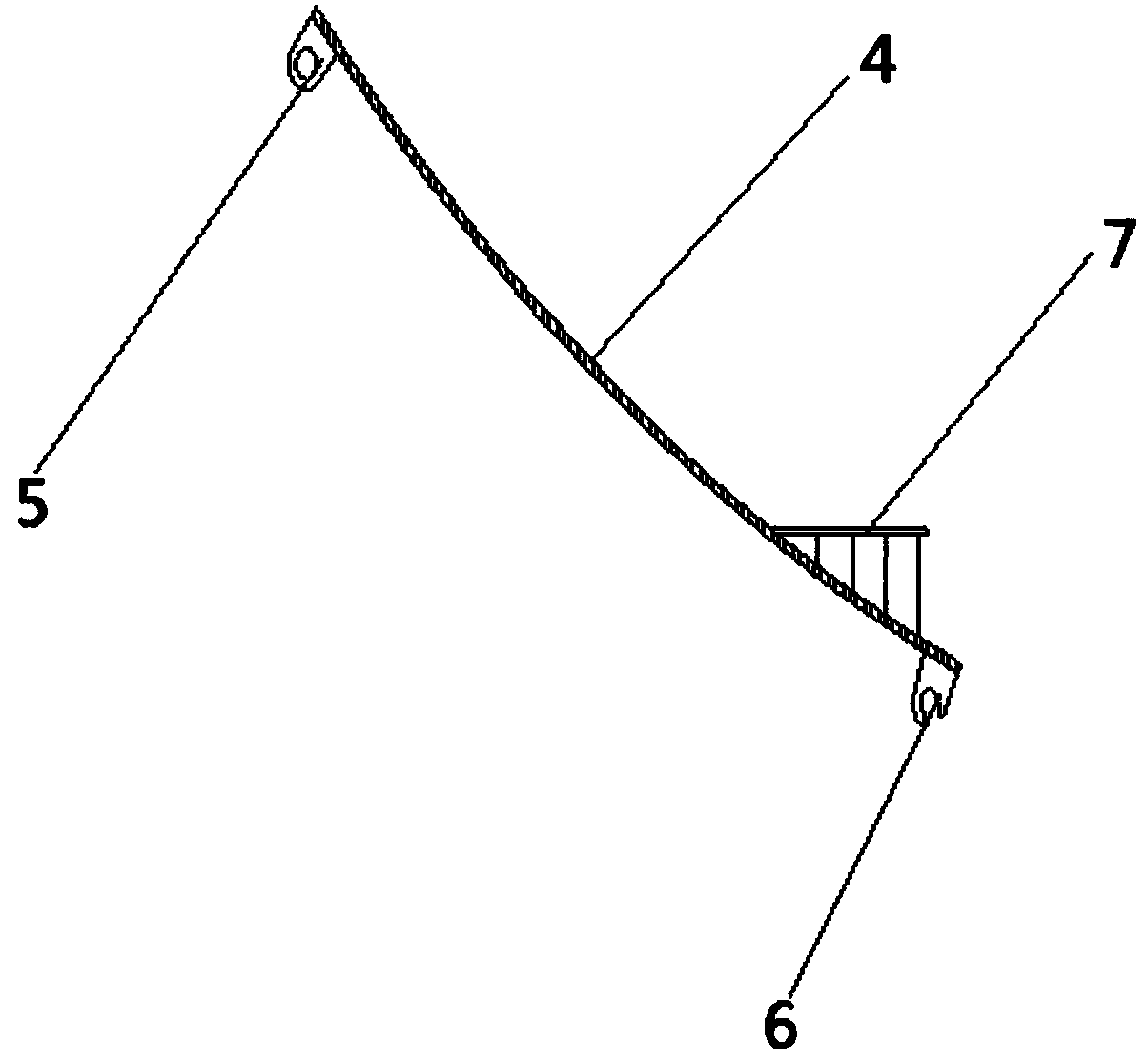

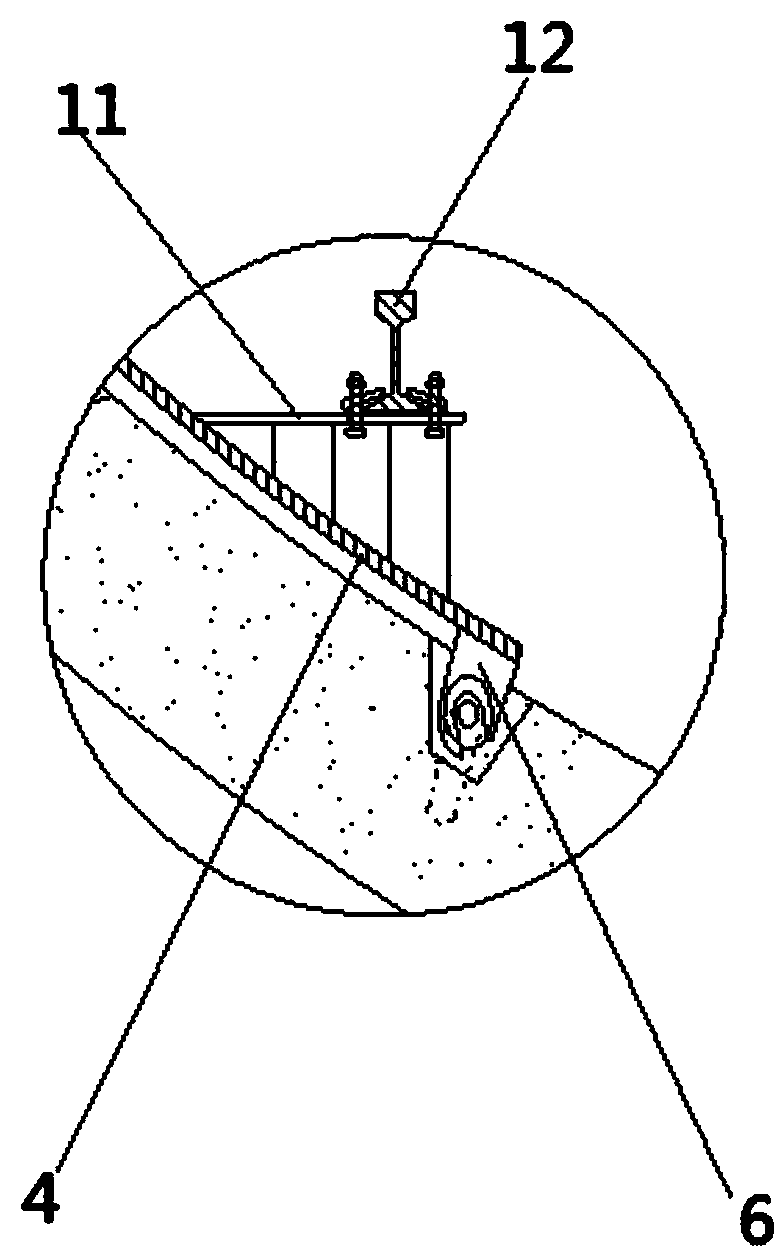

[0029] Such as Figure 1 to Figure 4 As shown, a sleeper of a shield machine trolley and a battery car system, including a shield tunnel 1, the shield tunnel 1 is provided with an upper sleeper 2 and a lower sleeper 3 that are detachably connected, and the upper sleeper 2 includes a The upper segment 4 matched with the shield tunnel 1 is provided with an upper ear plate 5, a lower ear plate 6, and a trolley traveling sleeper 7, and the upper segment 4 is provided with a bent bolt screw head 8. The lower sleeper 3 includes a bottom support segment 9, and the bottom support segment 9 is provided with a battery car walking sleeper 10; the upper sleeper 2 and the lower sleeper 3 are arranged on two planes.

[0030] The trolley traveling rail 7 includes a traveling platform 11 and a trolley track 12, the traveling platform 11 is horizontally arranged and fixedly connected with the upper segment 4, and the trolley track 12 is detachably installed on the traveling platform 11.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com