Organic light-emitting diode

A technology of light-emitting diodes and organic light-emitting layers, applied in electrical components, circuits, electric solid devices, etc., can solve the problems of poor dispersion, disorderly arrangement of carbon nanotubes, uneven dispersion, etc., and achieve good dispersion and enhanced electron transmission. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

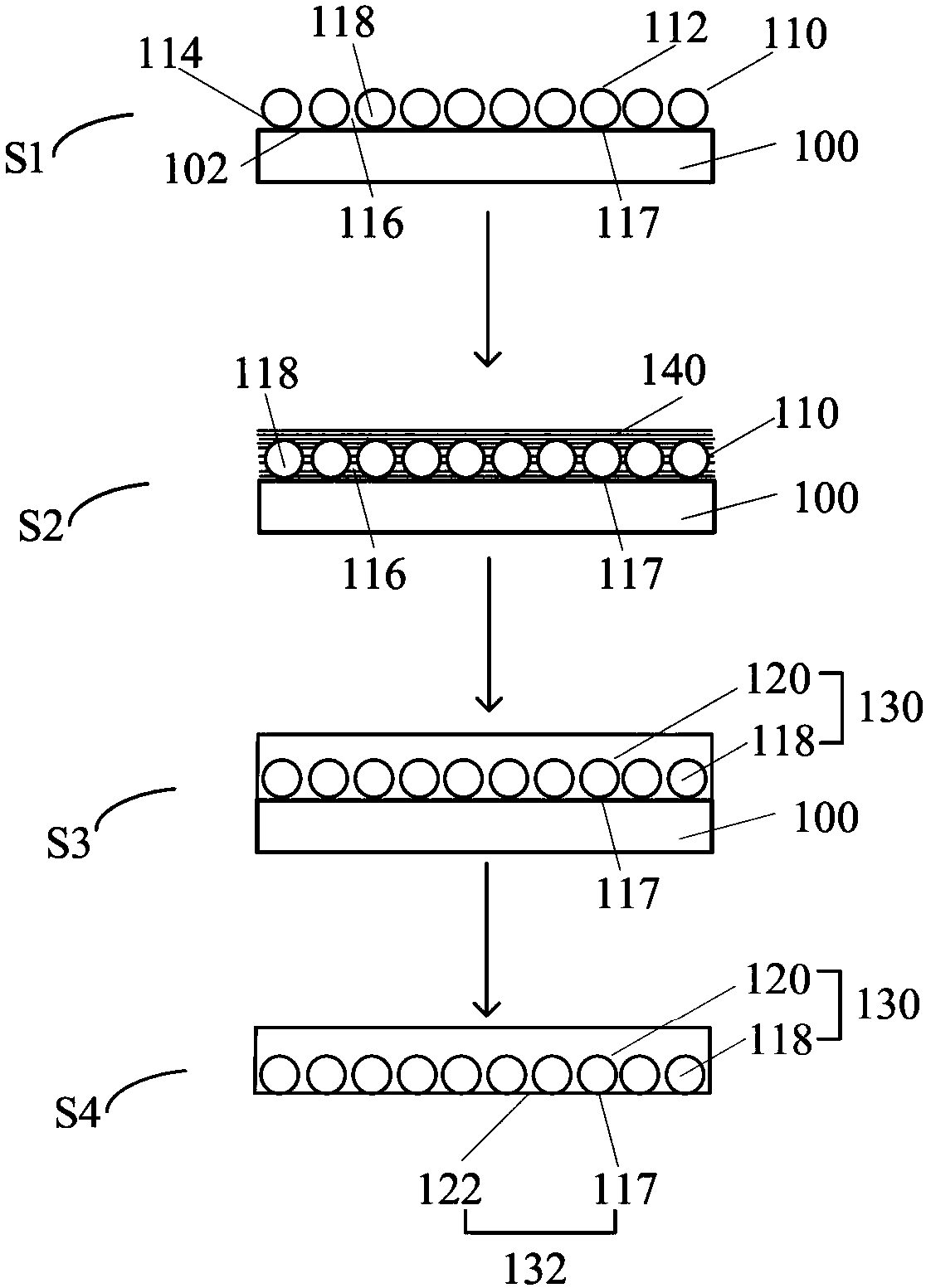

[0056] See figure 1 , the first embodiment of the present invention provides a method for preparing a carbon nanotube composite structure 130, comprising the following steps: S1, disposing a carbon nanotube structure 110 on the first surface 102 of a substrate 100, the carbon nanotube structure 110 There is an opposite second surface 112 and a third surface 114, the third surface 114 is in direct contact with the first surface 102 of the substrate 100; S2, providing a monomer solution 140, the monomer solution 140 is to disperse the monomer into the organic formed in a solvent, and apply the monomer solution 140 to the carbon nanotube structure 110; S3, polymerize the monomer; S4, remove the substrate 100 to obtain the carbon nanotube composite structure 130.

[0057]In step S1 , the carbon nanotube structure 110 includes a plurality of uniformly distributed carbon nanotubes 118 , with gaps 116 between adjacent carbon nanotubes 118 . The plurality of carbon nanotubes 118 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com