Counter flow type multistage spray device

A spray device and counter-flow technology, applied in the field of waste gas treatment equipment, can solve the problems of increasing the treatment cost of absorbing liquid, failing to achieve the treatment effect, and low waste gas absorption rate, reducing the floor space, improving the purification treatment, reducing the Effects of connecting accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

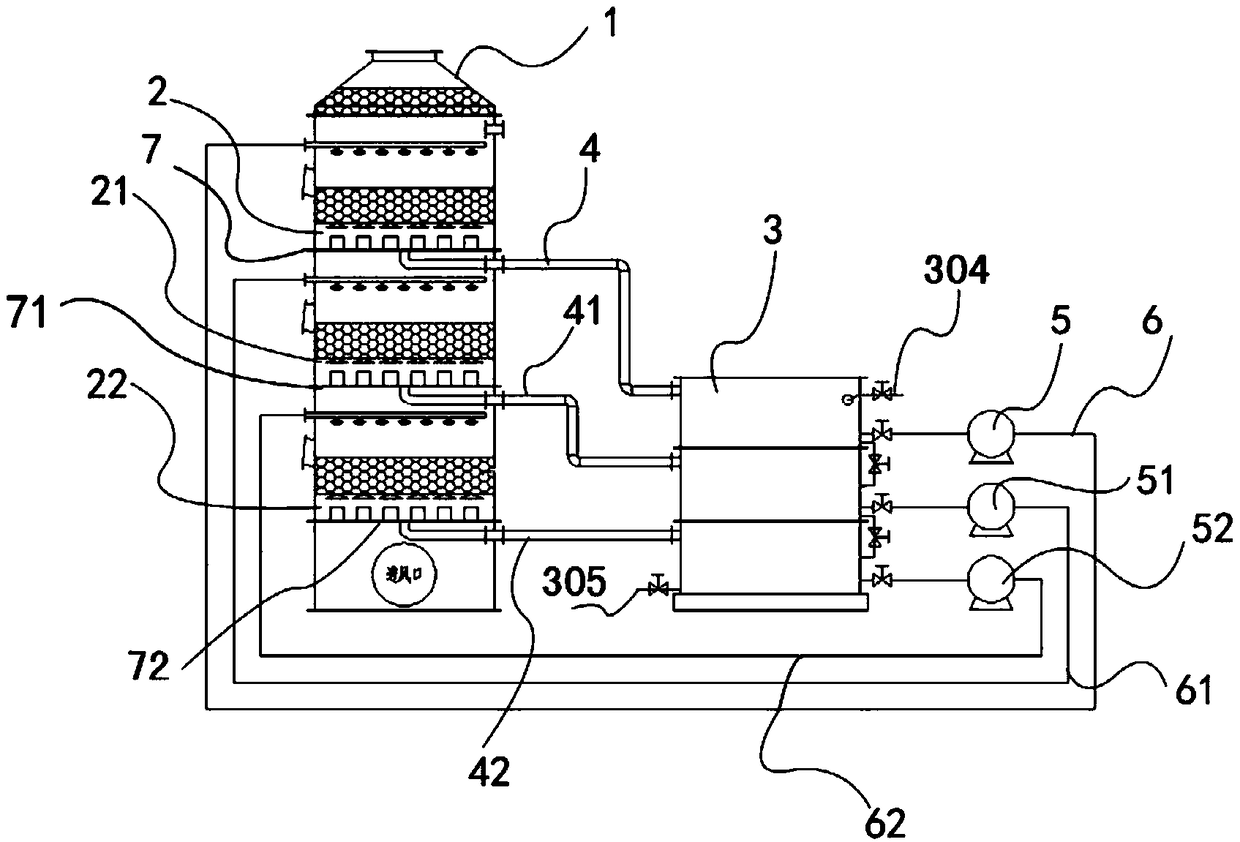

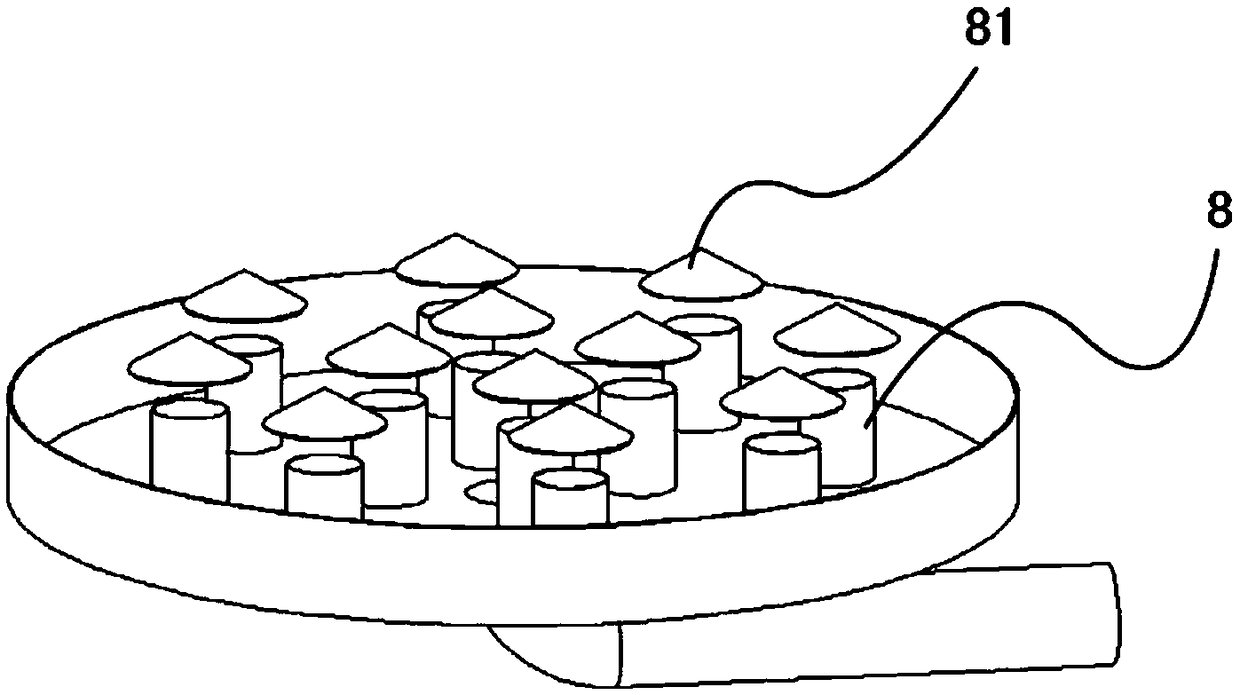

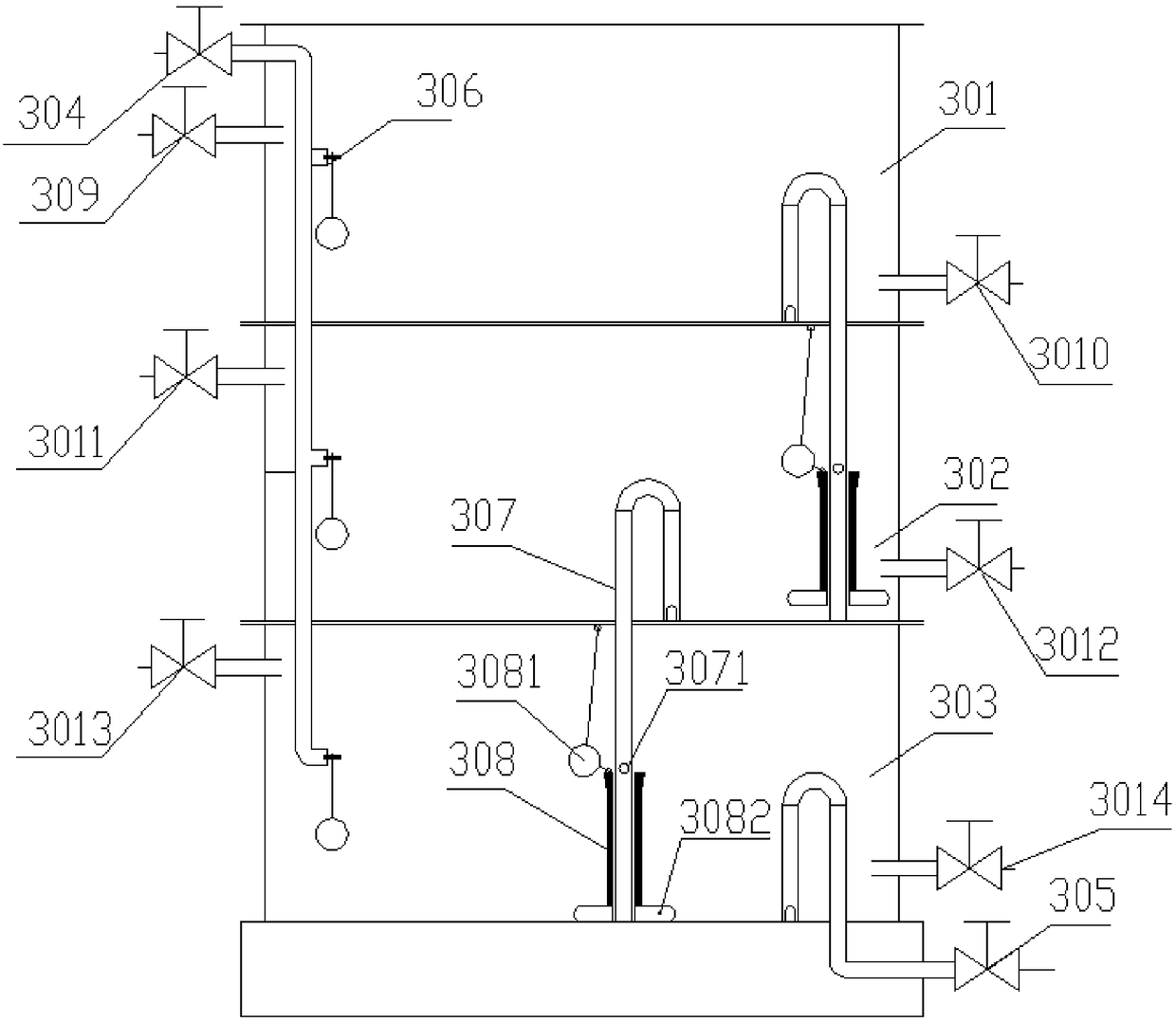

[0030] An embodiment of the shower device of the present invention, such as Figure 1~3As shown, it includes a spray tower 1, which is provided with three first-stage purification equipment 2, second-stage purification equipment 21 and third-stage purification equipment 22 arranged up and down in the spray tower 1, and each purification equipment includes a spray Assemblies, the packing layer and the sump for collecting the absorption liquid are fixed in sequence under the spray assembly. The top of the sump is provided with an opening, and the side wall of the sump is closely attached to the inner wall of the spray tower 1. In the sump There is a vent pipe 10 for the waste gas below to pass through and is placed vertically. A water blocking cap 101 is provided above the upper port of the vent pipe 10. The water blocking cap 101 prevents liquid from flowing into the vent pipe 10. The bottom of each sump passes through The drain pipe is connected with a liquid storage tank 3; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap