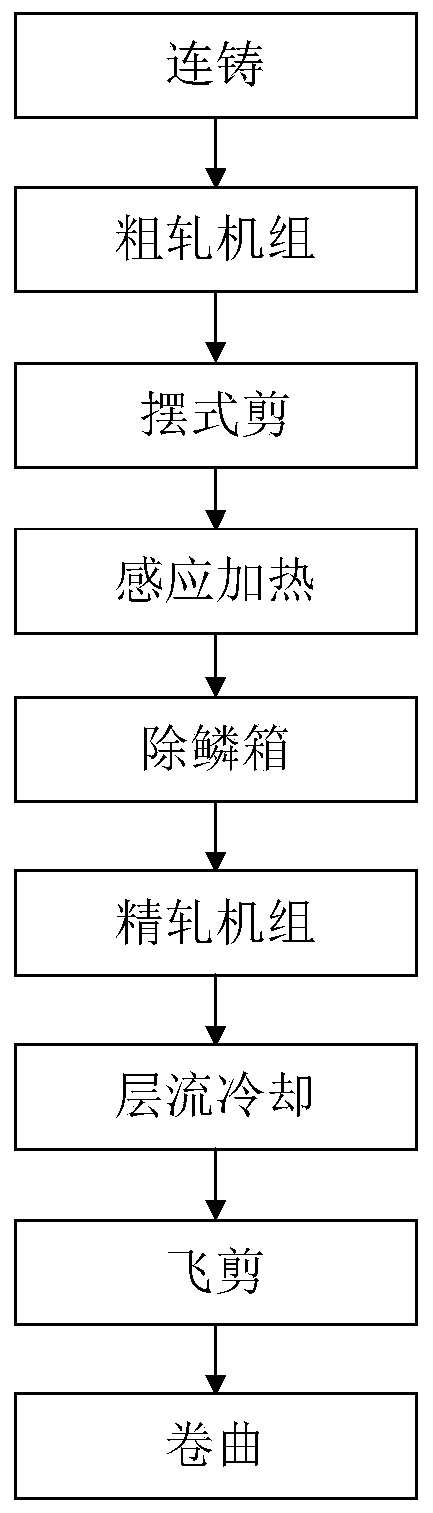

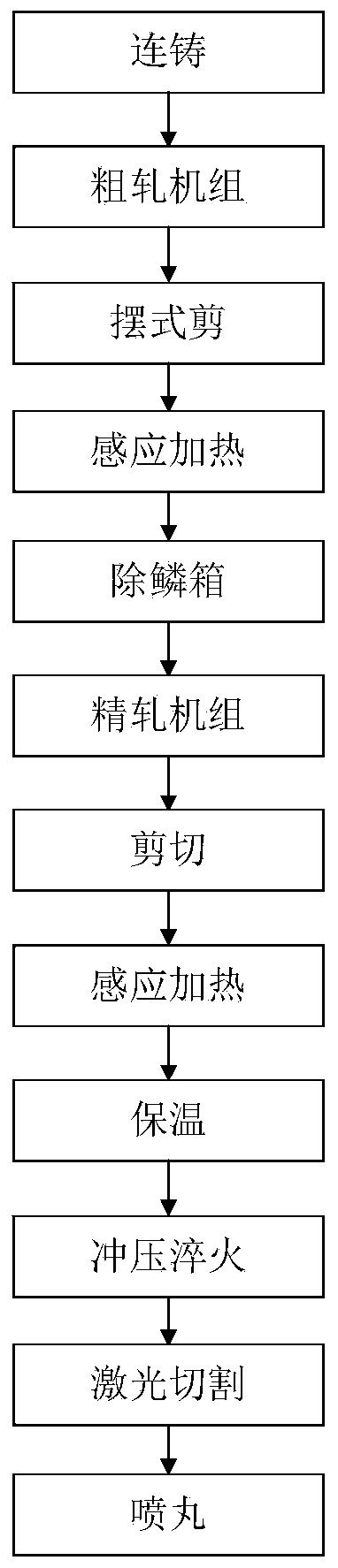

A short-process method for manufacturing high-strength steel plates and high-strength steel plates and applications thereof

A high-strength steel plate and short-process technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems that can not realize endless rolling production, affect the forming performance and surface quality of hot stamping materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, during the thin slab continuous casting and rolling process, the temperature of the thin slab after the continuous casting treatment is 1500°C, and then after the rough rolling treatment by the rough rolling unit, the temperature drops to 930°C, and the temperature rises to 1100°C after the induction heating treatment , the temperature dropped to 850°C after finishing rolling treatment by the finishing rolling unit.

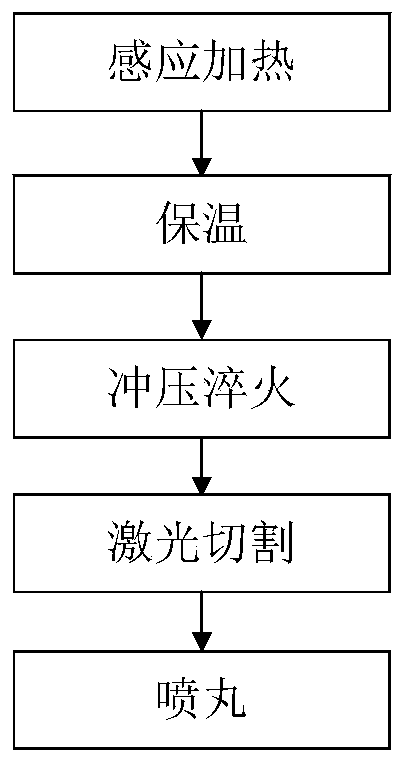

[0049] After the finishing treatment of the finishing rolling unit, the plate directly enters the hot stamping deep processing, and the shearing device cuts the plate into the shape and size required by the hot stamping die, and enters the subsequent process through the conveying roller table, and is processed in the hot stamping deep processing During the process, the temperature is 850°C, and the temperature is kept for 180-250s, so that the plate forms a stable austenite structure.

[0050] After heat preservation, the high-temperatu...

Embodiment 2

[0055] In this embodiment, during the thin slab continuous casting and rolling process, the temperature of the thin slab after continuous casting is 1500°C, and then after the rough rolling treatment of the rough rolling unit, the temperature drops to 950°C, and the temperature rises to 1150°C after induction heating , the temperature dropped to 880°C after finishing rolling treatment by the finishing rolling unit.

[0056] After the finishing treatment of the finishing rolling unit, the plate directly enters the hot stamping deep processing, and the shearing device cuts the plate into the shape and size required by the hot stamping die, and enters the subsequent process through the conveying roller table, and is processed in the hot stamping deep processing During the process, the temperature is 880°C, and the temperature is kept for 180-250s, so that the plate forms a stable austenite structure.

[0057] After heat preservation, the high-temperature plate is transferred to t...

Embodiment 3

[0062] In this embodiment, during the thin slab continuous casting and rolling process, the temperature of the thin slab after continuous casting is 1500°C, and then after the rough rolling treatment of the rough rolling unit, the temperature drops to 970°C, and the temperature rises to 1200°C after induction heating , the temperature dropped to 910°C after finishing rolling treatment by the finishing rolling unit.

[0063] After the finishing treatment of the finishing rolling unit, the plate directly enters the hot stamping deep processing, and the shearing device cuts the plate into the shape and size required by the hot stamping die, and enters the subsequent process through the conveying roller table, and is processed in the hot stamping deep processing During the process, the temperature is 910°C, and the temperature is kept for 180-250s to make the plate form a stable austenite structure.

[0064] After heat preservation, the high-temperature plate is transferred to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com