Full-automatic mechanical processing equipment

A mechanical processing and fully automatic technology, which is applied in the direction of metal processing equipment, measuring/indicating equipment, drilling/drilling equipment, etc., can solve the problems such as the inability to automatically adjust the processing position, the cover is not tightly covered, and the drill bit is stuck. Achieve the effects of saving working time, convenient lighting, and buffering vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

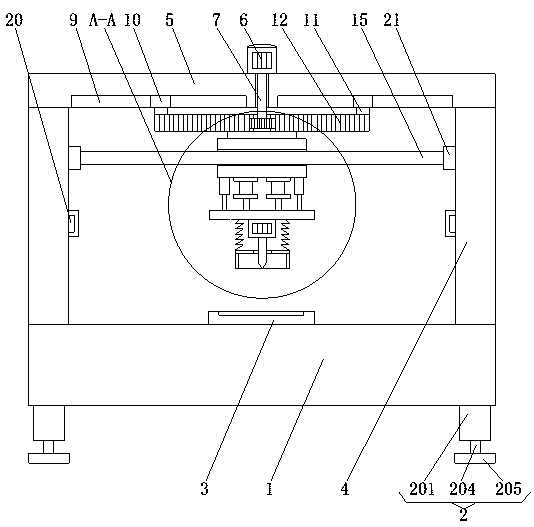

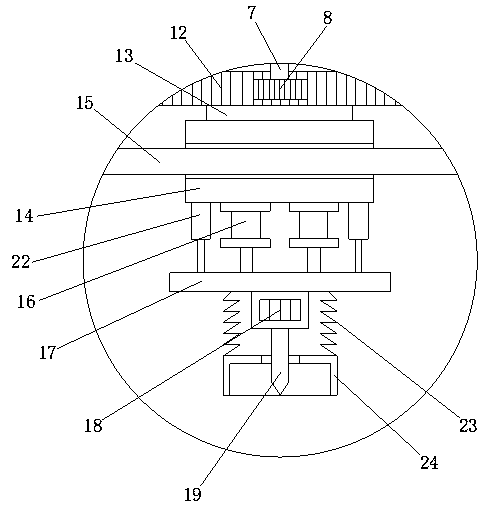

[0022] The first embodiment: please refer to Figure 1-3 , A fully automatic machining equipment, including an operating table 1, two supporting devices 2 are symmetrically provided on the left and right sides of the bottom of the operating table 1, the supporting device 2 includes a connecting seat 201, the top of the connecting seat 201 and the operating table 1 The bottom is fixedly connected, the top of the inner wall of the connecting seat 201 is fixedly connected with a buffer spring 202, the bottom of the buffer spring 202 is fixedly connected with a connecting slider 203 slidingly connected with the inner wall of the connecting seat 201, and the bottom of the connecting slider 203 is fixedly connected with a support leg 204 , The bottom of the support leg 204 penetrates through the connecting seat 201 and extends to the outside of the support seat 205 to be fixedly connected to the support seat 205. The support device 2 is provided to buffer the vibration of the operatin...

no. 2 approach

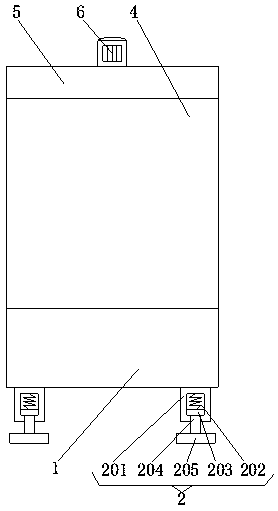

[0025] The second embodiment: as shown in claim 1, a fully automatic machining equipment, comprising an operating table 1, the left and right sides of the bottom of the operating table 1 are symmetrically provided with two supporting devices 2, the operating table 1 The fixed mold 3 is fixedly connected to the midpoint of the top of the operating table 1, the left and right sides of the top of the operating table 1 are fixedly connected to the supporting plates 4, and the tops of the two supporting plates 4 are fixedly connected by the top plate 5. A drive motor 6 is fixedly connected to the midpoint, and a drive shaft 7 is fixedly connected to the output shaft of the drive motor 6. The bottom of the drive shaft 7 penetrates the top plate 5 and extends below it to be fixedly connected with a drive gear 8. The bottom of the top plate 5 and the left and right sides of the drive shaft 7 are provided with sliding grooves 9, the inner wall of the sliding groove 9 is slidably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com