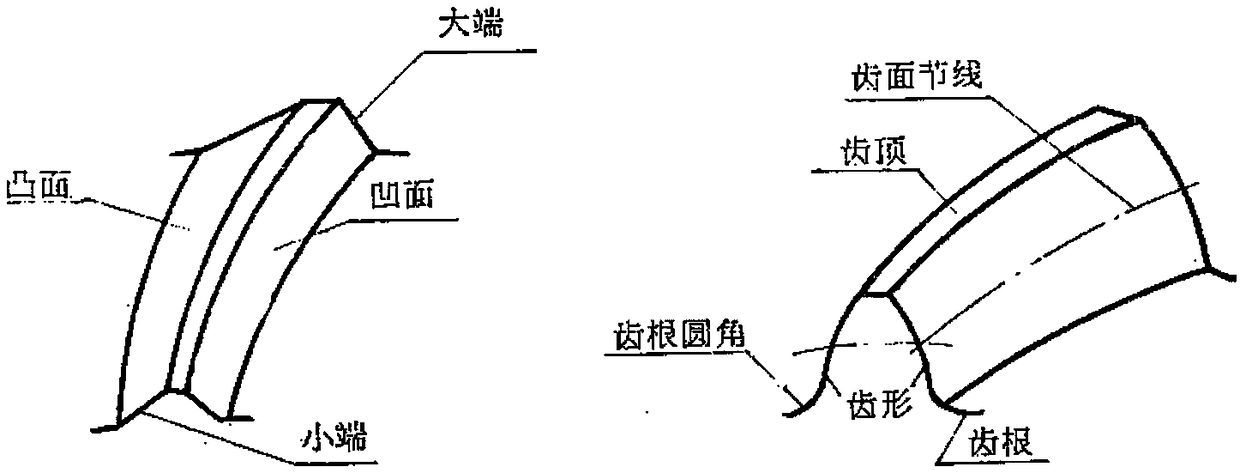

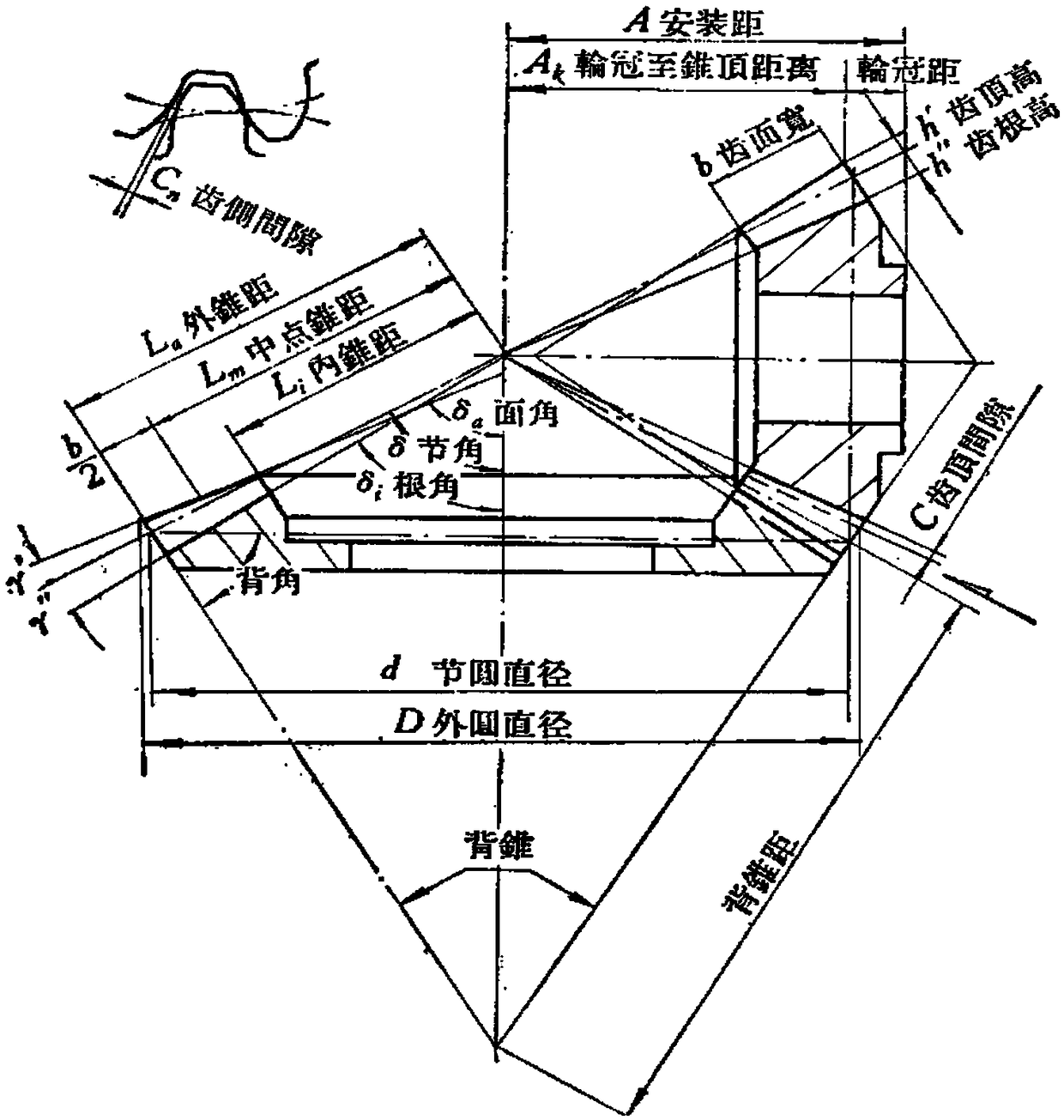

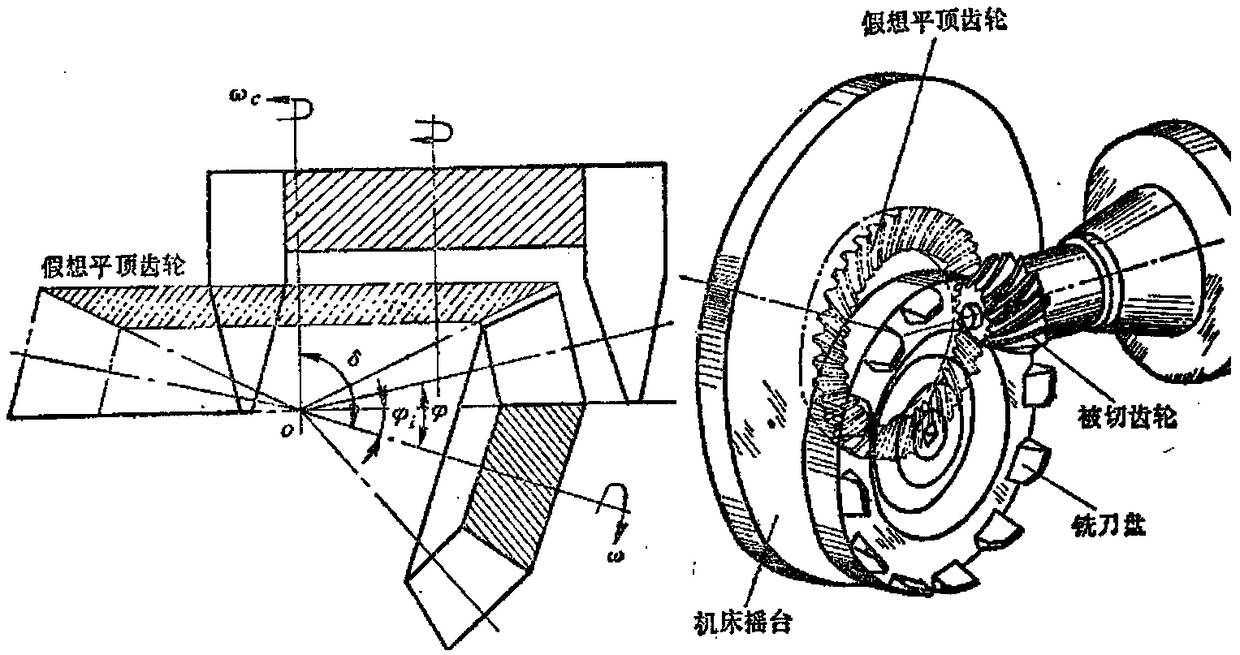

Arc bevel gear machining method

A processing method and technology of gears, applied in the directions of belts/chains/gears, gear teeth, components with teeth, etc., can solve the problems of reducing processing efficiency, failure of small wheel matching, increasing gear processing time, etc., and achieving good symmetry , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 23Z31

[0039] Example 1 Z23Z31M6.35b32

[0040] Step 1: Look up the table to obtain the height variation coefficient and tangential variation coefficient of the large wheel and the small wheel, and calculate the number of teeth of the crown wheel, the length of the midpoint generatrix, and the overall height of the teeth;

[0041] Table 1 Gleason system, coefficient of variation addendum and root coefficient

[0042] M>1.25, β=35°, fO=0.85, CO=0.188, δ=90°

[0043]

[0044] Helix angle β=35° Transmission ratio i=Z 2 / Z 1 =31 / 23=1.347826, the high variation coefficient ξ=0.18 is obtained by looking up the table

[0045] Table 2 Selection of the nominal diameter of the root spiral bevel gear β35° milling cutter

[0046]

[0047] Nominal diameter of β35° milling cutter: Du12″

[0048] Table 3 Du12″Z23Z31M6.35b32 small wheel and large wheel tooth blank dimensions, axis angle Σ=90° pressure angle α=20° helix angle β=35°fo=0.85, C O =0.188

[0049]

[0050]

[0051] Step...

Embodiment 2

[0074] Standard root N7.5 # Small helical bevel gears. Use double-sided fine cutting knife number N=7.5 (average knife number N7.5 # ) When the cutterhead is processing a spiral bevel gear, one tooth groove of the gear is processed so that the two sides of the tooth groove (concave surface, convex surface) are at the intersection of the pitch cone and the midpoint of the tooth surface, and the helix angle at these two points is nearly equal, β 凸 = β 凹 , the meshing angles are nearly equal. alpha 凸 = α 凹 . In this way, the gear pairs for processing large and small wheels can be conjugated. Use this principle to process spiral bevel gears. There is no need to configure the contact area, according to the cutter number N=7.5 # The helix angle β is adopted, and the general helix angle β is 10° to 20°. To ensure that the midpoint helix angle remains unchanged, the helix angle at the intersection of the midpoints of the concave and convex surfaces is nearly equal by changing...

Embodiment 3

[0120] Standard root 1:1 spiral bevel gear machining method. The standard root 1:1 bevel gear means that the number of teeth, modulus, tooth width, total tooth height, addendum height, helix angle and pressure angle are exactly the same. When processing, use the nominal diameter of the milling cutter, tool number, and wrong tool All the same milling cutter discs are used, and a milling cutter disc is generally used. When machining on a spiral gear machine, the angle of the tool position, the angle of the cutting root taper, and the amount of bed retraction do not need to be changed, but the angle Q of the rocking table of the left and right spiral bevel gears is different. It can be processed by a spiral gear machine, and the ideal conjugative i=1 gear pair can be cut out, without the need for a contact area. The length ratio of the contact area after processing: gears that should be less than 0.7, greater than and close to 0.3. The specific calculation steps are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com