Live working robot control system

A technology of control system and live working, which is applied in the field of electric power, can solve problems such as not intuitive enough, falling, complex environment, and untimely response to special situations, etc., so as to achieve the effect of improving efficiency, increasing fault tolerance rate, and reducing work risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

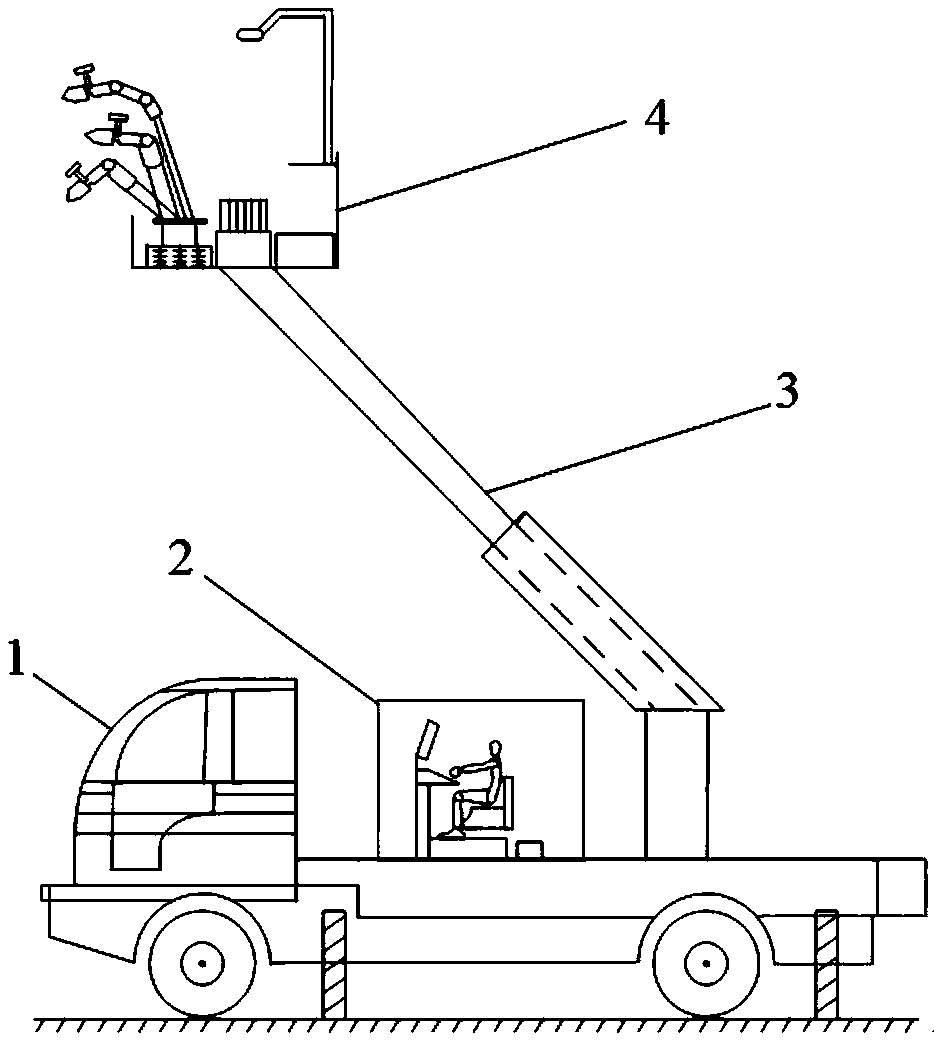

[0039] Such as figure 1As shown, the live working robot system includes an insulated bucket truck, a control room mounted on the insulating bucket truck, and a robot platform connected to the bucket truck through a telescopic arm. A generator is mounted on the insulated bucket truck to supply power to the control room and robot platform. The staff drives the insulated bucket arm truck to the live working object, adjusts the height of the robot platform by adjusting the driving device of the telescopic arm, and performs subsequent live working operations.

[0040] The live working robot includes an insulating arm truck 1 , a control room 2 , a telescopic arm 3 and a robot platform 4 . Among them, the control room 2 and the telescopic arm 3 are erected on the insulated bucket truck 1, and the end of the telescopic arm 3 is connected to the robot platform 4, and the fiber optic Ethernet communication or wireless network communication is used between the robot platform 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com