An endpoint monitoring method for backhole etching of high electron mobility transistors

A technology with high electron mobility and transistors, which is applied in the testing/measurement of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of weak signal of the endpoint monitoring system, small proportion of exposed area of back holes, and difficult identification, etc., to achieve High practical value, improved process reliability, improved accuracy and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For simplicity, some technical features known to those skilled in the art are omitted from the following description.

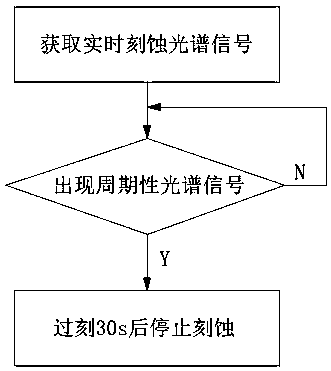

[0019] In this embodiment, a silicon carbide-based gallium nitride high electron mobility transistor is taken as an example. The complete process of back hole etching and endpoint monitoring is as follows:

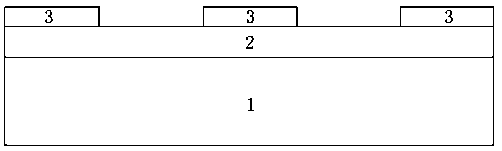

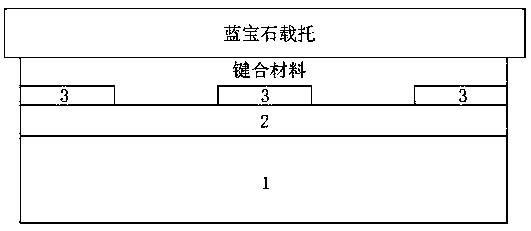

[0020] A. Two kinds of metals are grown alternately on the wiring layer of the device front process to form a periodic metal layer 3, and the periodic metal layer 3 is located above the position of the through hole to be etched on the back, such as figure 2 Shown; Alternately grown metals are platinum and gold, or nickel and gold, that is, a periodic structure of Pt / Au / Pt / Au / Pt / Au or Ni / Au / Ni / Au / Ni / Au, typical thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com