Cab stabilizer bar and assembly process thereof

An assembly process, stabilizer bar technology, applied in the direction of transportation and packaging, cantilever installed on the pivot, interconnection system, etc., can solve the problems of high equipment control requirements, easy loose connection strength, poor welding performance, etc., to achieve welding The efficiency and stability of welding quality are improved, the efficiency of fully automatic control of the welding process is high, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problem solved by the present invention, the adoption scheme and the expression of the realization effect clearer, the following will be further described in detail in conjunction with the accompanying drawings, and all examples are only part of the present invention, not all examples, and those skilled in the art have no creativity Other examples of achievements all belong to the protection scope of the present invention.

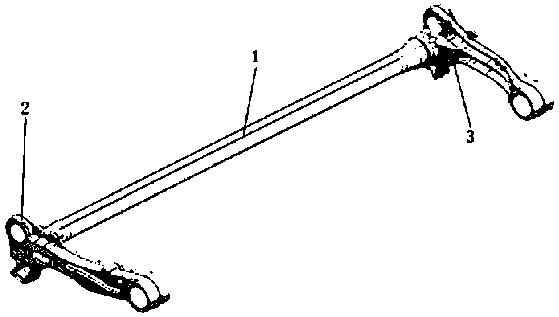

[0024] Combine below figure 1 The specific embodiment of the present invention is described further:

[0025] Such as figure 1 As shown, a cab stabilizer bar includes a hollow tube body 1 , a left swing arm 2 and a right swing arm 3 . The hollow tube rod body 1 is a 42CrMo4 alloy steel pipe with a thickness of 7mm. The left swing arm 2 and the right swing arm 3 are GGG40 ductile iron. Since the hollow tube rod body 1 adopts a hollow structure, the left swing arm 2 and the right swing arm 3 adopt ductile iron. Compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com