Foundation and upper steel structure full modular assembly elevator shaft

A technology for elevator shafts and steel structures, which is applied to elevators, transportation and packaging, and elevators in buildings. It can solve the high precision requirements for component prefabrication and on-site hoisting, and the shaft foundation has not realized prefabricated construction. Construction and other problems, to achieve the effect of solving complex prefabricated components, convenient and quick installation, and little impact on the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will now be described in further detail with reference to the drawings.

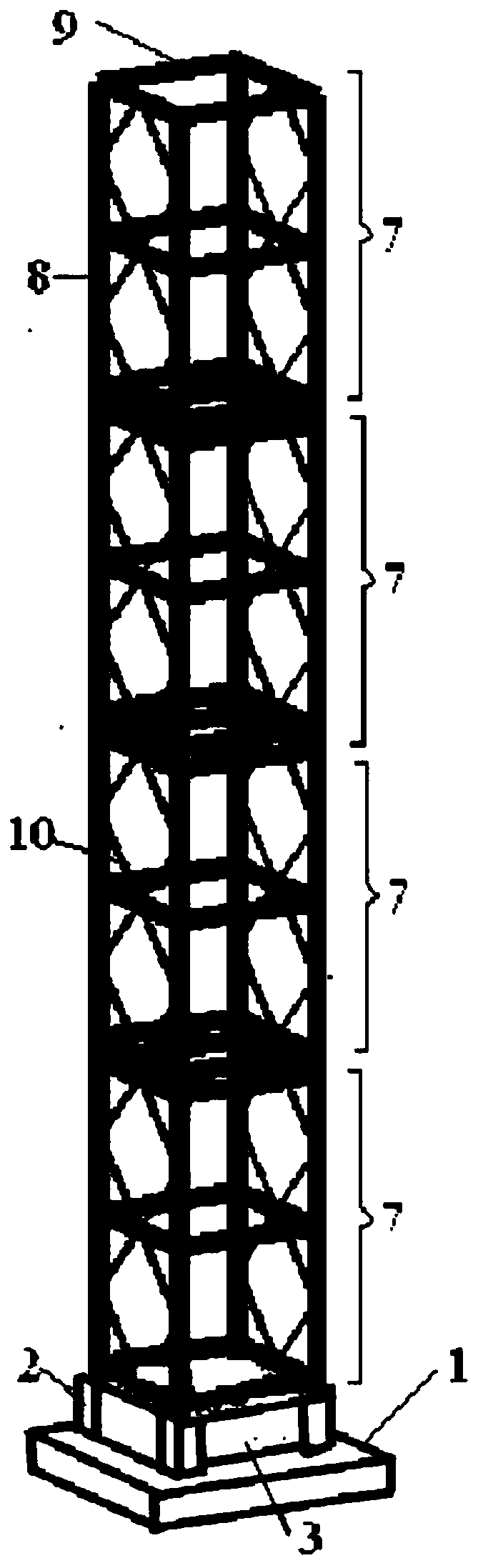

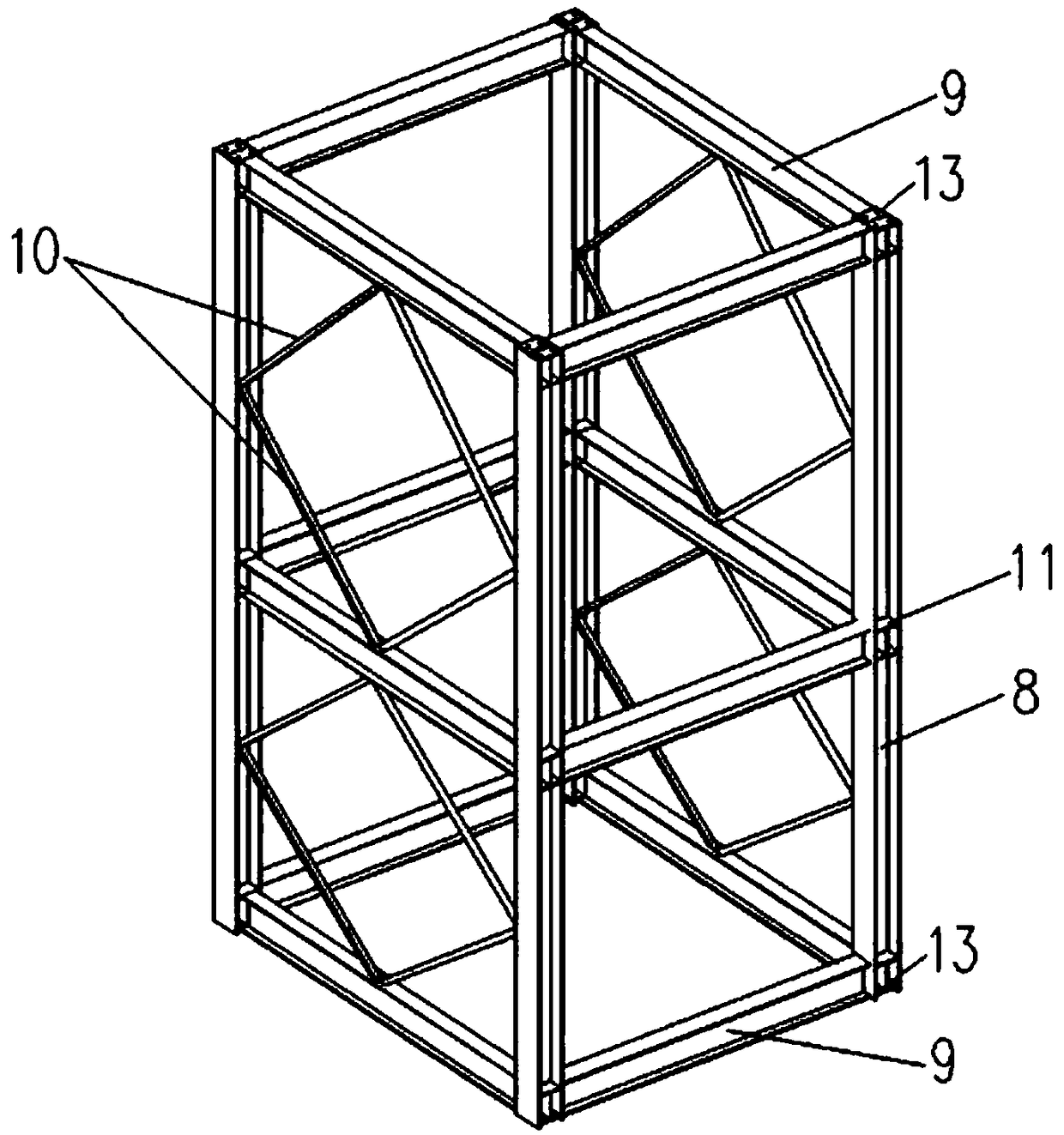

[0033] Such as Figure 1 to Figure 8 A fully modular assembled elevator hoistway with a foundation and an upper steel structure is shown, including a foundation and a hoistway. The foundation is a prefabricated assembly with embedded parts 6 fixed at the upper end. The hoistway consists of a number of standard steel structure modular units 7 It is assembled layer by layer, and the steel structure standard module unit 7 at the bottom layer is fixed to the embedded part 6 by bolts.

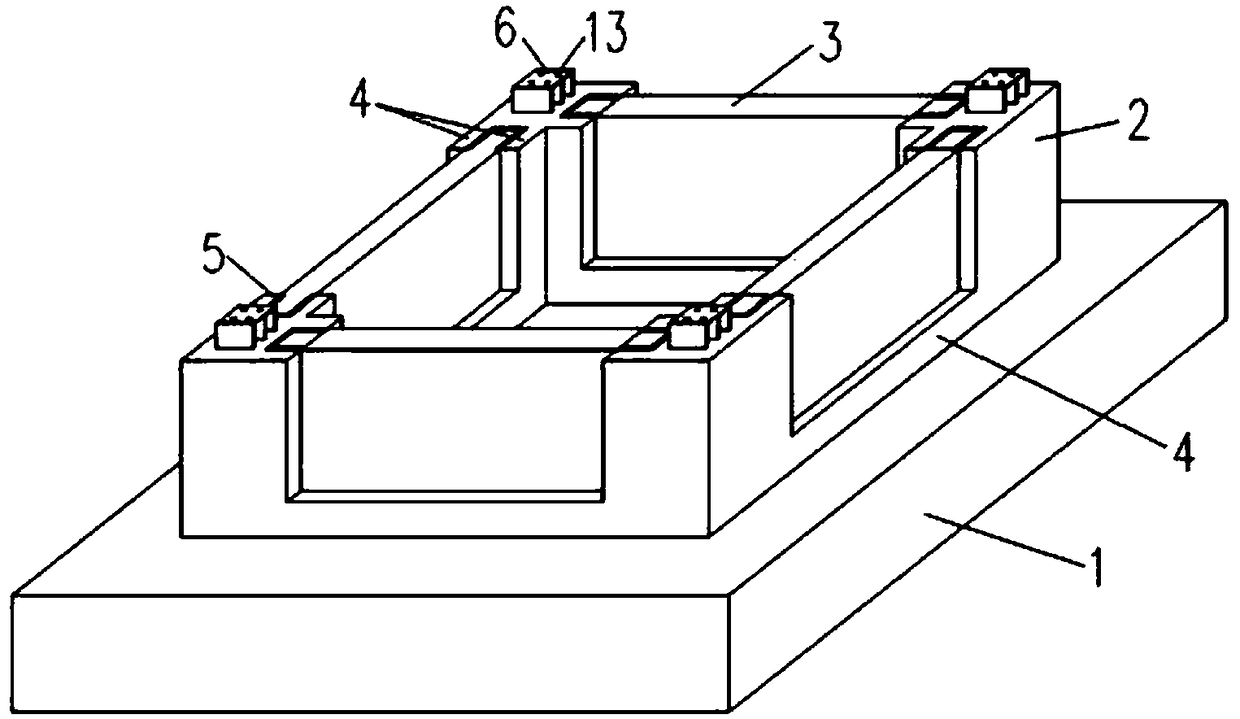

[0034] The foundation includes a bottom plate 1, a column pier 2, and four prefabricated side plates 3. The bottom plate and the column pier are prefabricated as a whole. The column pier is provided with four troughs 4, and each trough 4 includes two There are two vertical and one horizontal grooves, each of the prefabricated side plates is provided with tongues and grooves 5 on three sides, and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com