Method for recycling sodium sulfite from desulfurization waste solution

A technology of desulfurization waste liquid and sodium sulfite, which is applied in the preparation of alkali metal sulfite, purification of alkali metal sulfite/sulfite, etc. It can solve the problems of easy production of by-products, complicated process, and insufficient recovery of sodium sulfite, so as to avoid The effect of oxidation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

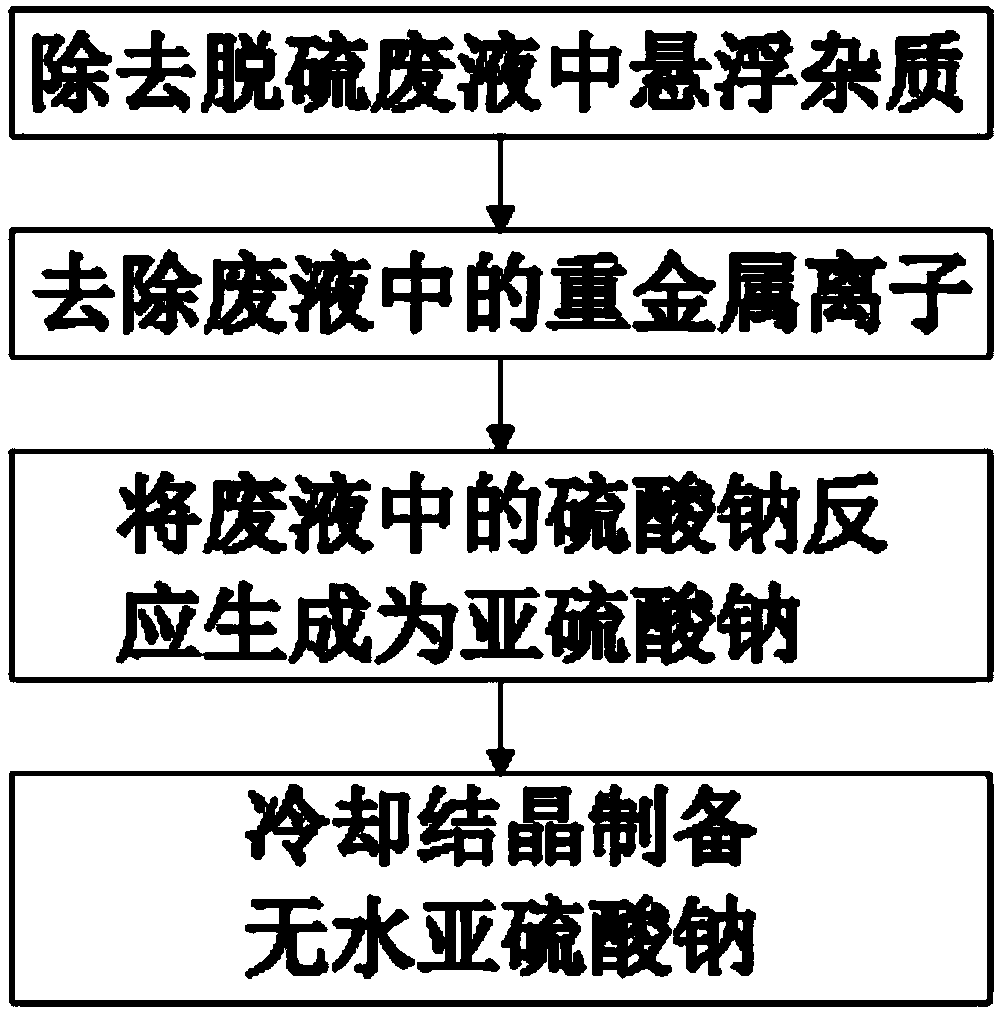

Image

Examples

Embodiment 1

[0033] The concrete steps of the method for reclaiming sodium sulfite from desulfurization waste liquid are as follows:

[0034] S1: Remove suspended impurities in the desulfurization waste liquid: select the desulfurization waste liquid to be treated, put the desulfurization waste liquid in a container, add activated carbon adsorbent to the container, and place the desulfurization waste liquid and the added adsorbent in a mixing device Stir and mix, the rotating speed of the mixing equipment is 200r / min, and the time of stirring and mixing is 5 minutes, the waste liquid after the above stirring and mixing is filtered through the filter screen to remove activated carbon adsorbent and suspended impurities, and the mesh diameter of the filter screen is 35 mesh , the filtered activated carbon adsorbent and suspended impurities are cleaned and continued to be used;

[0035]S2: Remove heavy metal ions in the waste liquid: inject HCl solution and NaCO into the desulfurization waste ...

Embodiment 2

[0039] The concrete steps of the method for reclaiming sodium sulfite from desulfurization waste liquid are as follows:

[0040] S1: Remove suspended impurities in the desulfurization waste liquid: select the desulfurization waste liquid to be treated, put the desulfurization waste liquid in a container, add activated carbon adsorbent to the container, and place the desulfurization waste liquid and the added adsorbent in a mixing device Stir and mix, the rotating speed of the mixing equipment is 210r / min, and the time of stirring and mixing is 6 minutes, the waste liquid after the above stirring and mixing is filtered through the filter screen to remove activated carbon adsorbent and suspended impurities, and the mesh diameter of the filter screen is 35 mesh , the filtered activated carbon adsorbent and suspended impurities are cleaned and continued to be used;

[0041] S2: Remove heavy metal ions in the waste liquid: inject HCl solution and NaCO into the desulfurization waste...

Embodiment 3

[0045] The concrete steps of the method for reclaiming sodium sulfite from desulfurization waste liquid are as follows:

[0046] S1: Remove suspended impurities in the desulfurization waste liquid: select the desulfurization waste liquid to be treated, put the desulfurization waste liquid in a container, add activated carbon adsorbent to the container, and place the desulfurization waste liquid and the added adsorbent in a mixing device Stir and mix, the rotating speed of the mixing equipment is 220r / min, and the time of stirring and mixing is 7 minutes, the waste liquid after the above stirring and mixing is filtered through the filter screen to remove activated carbon adsorbent and suspended impurities, and the mesh diameter of the filter screen is 35 mesh , the filtered activated carbon adsorbent and suspended impurities are cleaned and continued to be used;

[0047] S2: Remove heavy metal ions in the waste liquid: inject HCl solution and NaCO into the desulfurization waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com