Frost-resistant concrete and processing technique thereof

A processing technology and concrete technology, applied in the field of antifreeze concrete and its processing technology, can solve the problems of carcinogenicity, alkali return, influence on building quality and normal use, etc., and achieve the effect of environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

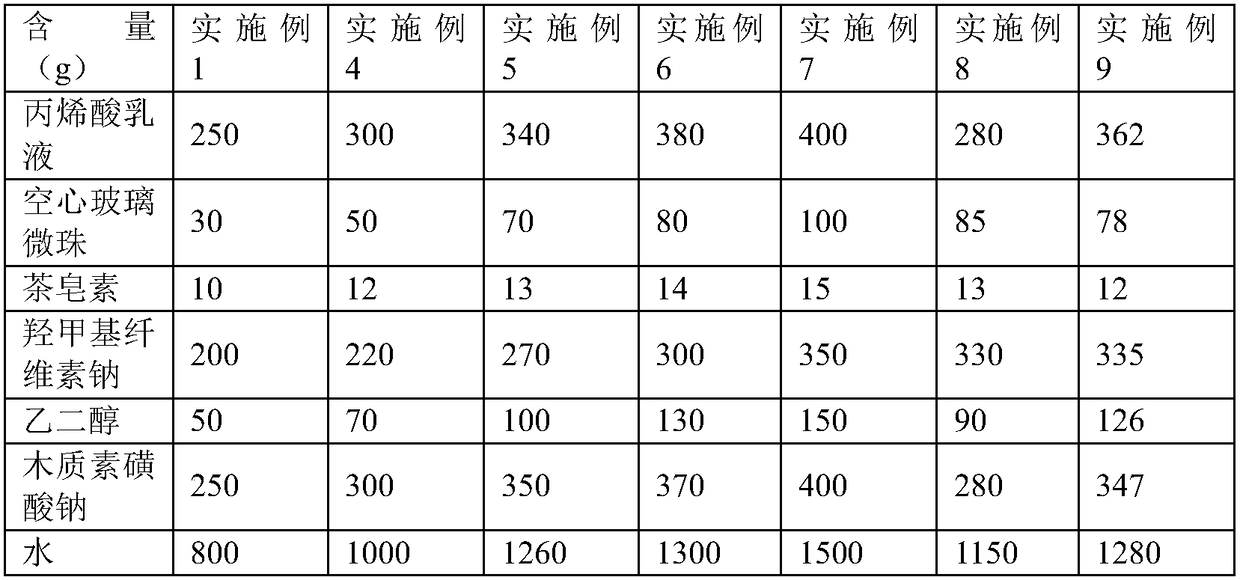

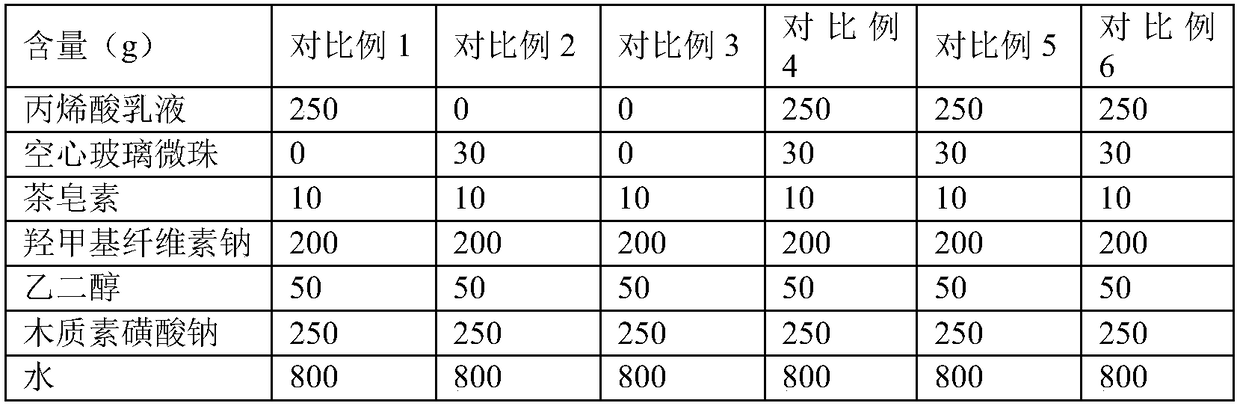

Embodiment 1

[0038] Preparation of antifreeze

[0039] Prepare the antifreeze agent through the following steps, according to the content of each raw material component in Table 1, mix tea saponin, sodium hydroxymethylcellulose, ethylene glycol, water reducing agent and 1 / 2 of the total amount of antifreeze agent water , and stir evenly to obtain mixture C; after mixing the acrylic emulsion and the remaining water, add hollow glass microspheres three times, specifically: add 2 / 4 of the total amount of hollow glass microspheres for the first time, and add 1 / 4 of the total amount of hollow glass beads, the third time adding 1 / 4 of the total amount of hollow glass beads, each time after adding the hollow glass beads, stir and mix at a speed of 30r / min for 3min to obtain the mixture D; Add the mixture D into the mixture C, and stir at a speed of 30r / min for 10min to obtain the antifreeze.

[0040] Frost-resistant concrete is processed through the following steps:

[0041] Raw material pretre...

Embodiment 2

[0044] Preparation of antifreeze

[0045] Prepare the antifreeze agent through the following steps, according to the content of each raw material component in Example 1, the water of tea saponin, sodium hydroxymethylcellulose, ethylene glycol, water reducing agent and 1 / 2 antifreeze agent water total amount Mix and stir evenly to obtain mixture C; after mixing the acrylic emulsion and the remaining water, add hollow glass microspheres three times, specifically: add 2 / 4 of the total amount of hollow glass microspheres for the first time, and add hollow glass microspheres for the second time Add 1 / 4 of the total amount of hollow glass beads, add 1 / 4 of the total amount of hollow glass beads for the third time, and stir and mix at a speed of 40r / min for 2min after each addition of hollow glass beads to obtain the mixture D ; Add the mixture D to the mixture C, and stir at a speed of 40r / min for 7min to obtain the antifreeze.

[0046] Frost-resistant concrete is processed through...

Embodiment 3

[0050] Preparation of antifreeze

[0051] Prepare the antifreeze agent through the following steps, according to the content of each raw material component in Example 1, the water of tea saponin, sodium hydroxymethylcellulose, ethylene glycol, water reducing agent and 1 / 2 antifreeze agent water total amount Mix and stir evenly to obtain mixture C; after mixing the acrylic emulsion and the remaining water, add hollow glass microspheres three times, specifically: add 2 / 4 of the total amount of hollow glass microspheres for the first time, and add hollow glass microspheres for the second time Add 1 / 4 of the total amount of hollow glass beads, and add 1 / 4 of the total amount of hollow glass beads for the third time. After each addition of hollow glass beads, stir and mix at a speed of 50r / min for 1min to obtain the mixture D ; Add the mixture D to the mixture C, and stir for 5 minutes at a speed of 50r / min to obtain the antifreeze.

[0052] Frost-resistant concrete is processed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com