Purification method of chromatographic pure 1,4-dioxane

A technology of dioxane and purification method, applied in the direction of organic chemistry, etc., can solve the problems such as failure to achieve purification effect, poor treatment effect, incomplete reaction, etc., to prevent iron impurities, complete reaction, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

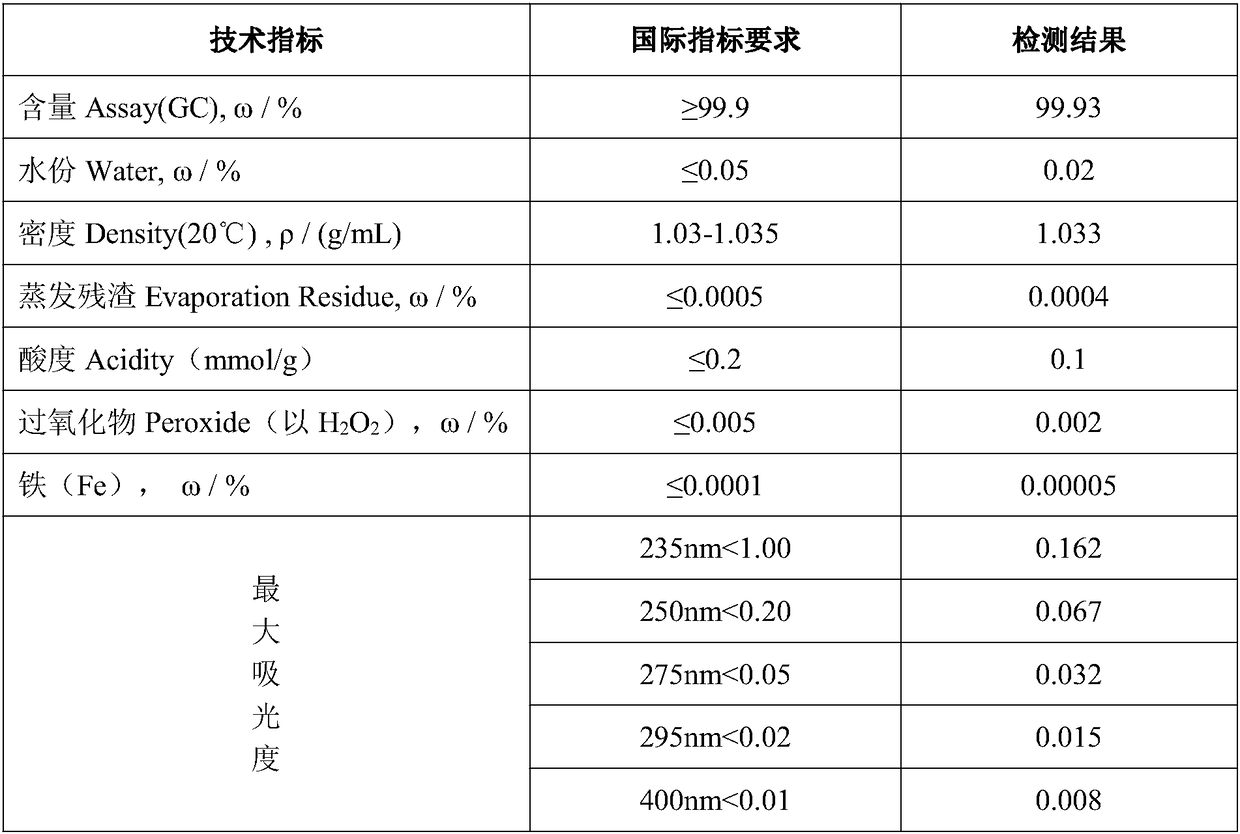

Embodiment 1

[0045] A kind of purification method of 1,4-dioxane, the steps are as follows:

[0046] 1) Hydrolysis: put 1,4-dioxane raw material with a content of 98.0% into the reactor, add a strong acidic cation exchange resin with a mass fraction of 0.02% to 0.05% into the reactor, and heat to 100 to 150°C , reflux for 1 to 2 hours, and hydrolyze the 2-methyl-1,3-dioxolane impurity in the raw material.

[0047] 2) Adsorption: Put the hydrolyzed 1,4-dioxane raw material into the cation exchange resin adsorption column, in which the adsorption column is 1.6m high and 4.2cm in diameter, and the height of the cation exchange resin product inside is 4 / 5 of the column height. Adsorption and filtration of some aldehyde impurities in the 1,4-dioxane raw material is carried out through a cation exchange resin adsorption column, and the filtration flow rate is 300-500mL / min;

[0048] 3) The raw materials adsorbed by cation exchange resin are then adsorbed by an activated carbon filter column. Th...

Embodiment 2

[0056] A kind of purification method of 1,4-dioxane, the steps are as follows:

[0057] 1) Hydrolysis: put 1,4-dioxane raw material with a content of 98.0% into the reactor, add a strong acidic cation exchange resin with a mass fraction of 0.02% to 0.05% into the reactor, and heat to 100 to 150°C , Reflux reaction for 1.5-2h, 2-methyl-1,3-dioxolane impurity in the raw material.

[0058] 2) Adsorption: Put the hydrolyzed 1,4-dioxane raw material into the cation exchange resin adsorption column, in which the adsorption column is 1.6m high and 4.2cm in diameter, and the height of the cation exchange resin product inside is 4 / 5 of the column height. Adsorption and filtration of some aldehyde impurities in the 1,4-dioxane raw material is carried out through a cation exchange resin adsorption column, and the filtration flow rate is 500-800mL / min;

[0059] 3) The raw material adsorbed by cation exchange resin is then adsorbed by an activated carbon column. The activated carbon colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com