Black mulch film for tobaccos and preparation method of black mulch film

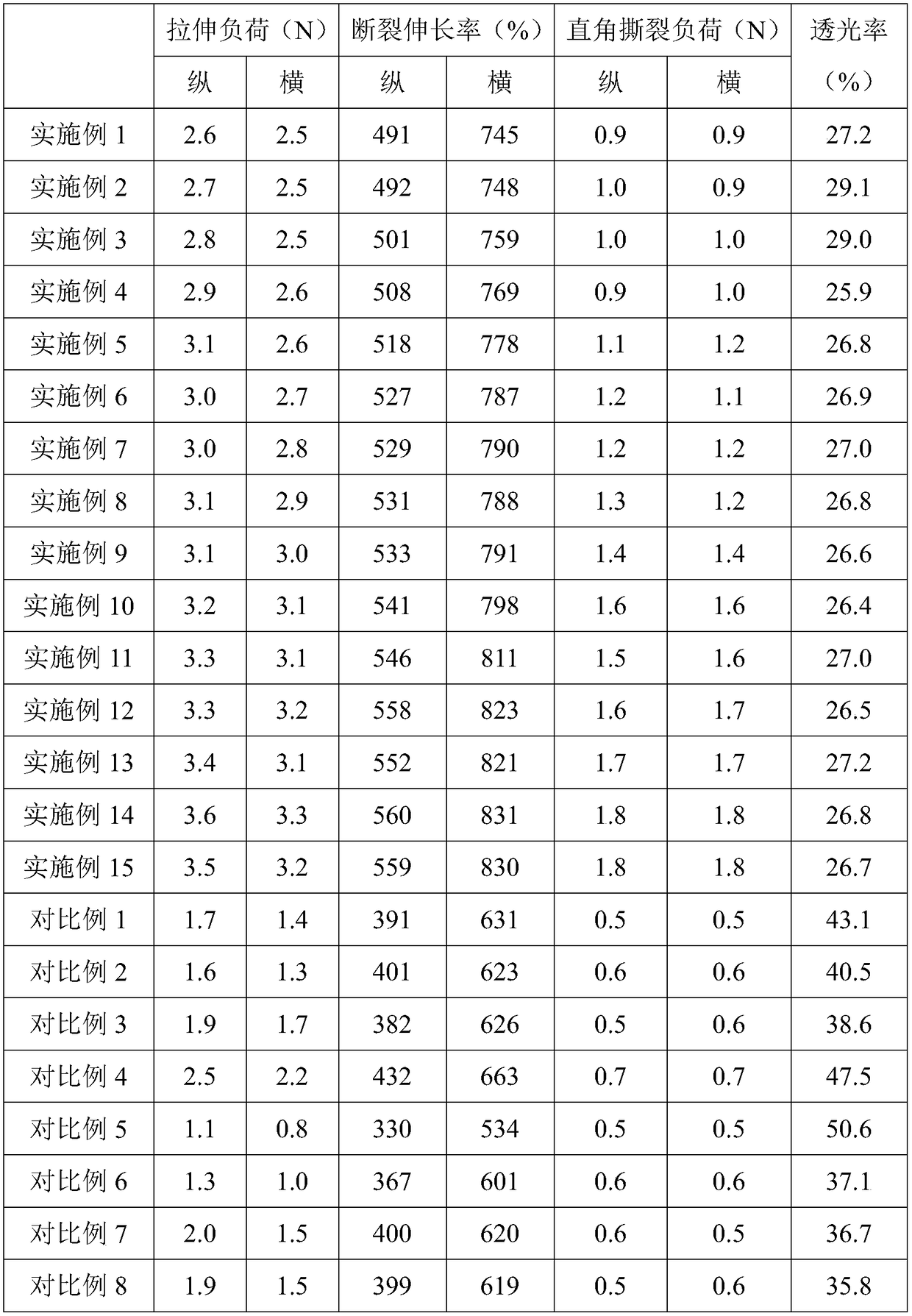

A black mulch film and technology for cigarettes, applied in the field of black mulch film for cigarettes and its preparation, can solve the problems of physical and mechanical property strength decline, easy aging, high light transmittance of the mulch film, etc., and achieve the convenience of mechanical and manual recycling and the strength of mechanical properties High and reduce the effect of recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

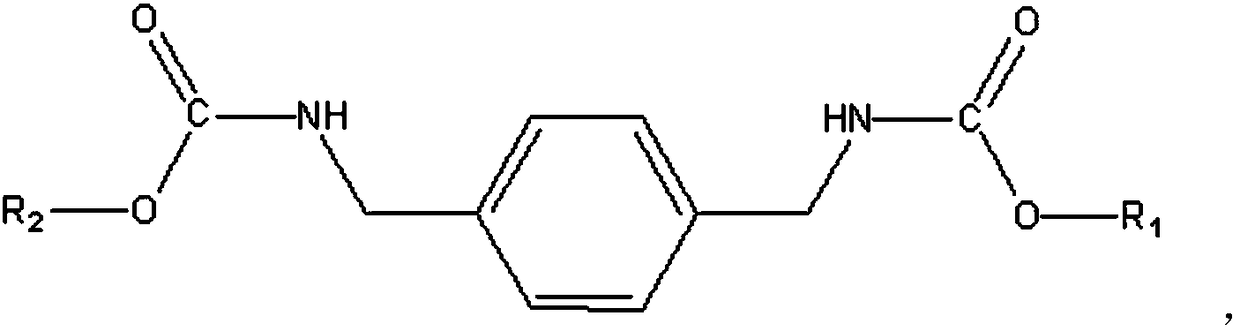

[0111] The preparation method of compound (A) described in the application, by weight, comprises the following steps:

[0112] (1) Weigh a certain amount of p-phenylene diisocyanate, containing R 1 Hydroxyl-terminated hydrocarbons of the group, containing R 2 The hydroxyl-terminated hydrocarbon of the group, the catalyst dibutyltin dilaurate and the solvent;

[0113] (2) Add the above-mentioned substances into a three-necked bottle equipped with a reflux condenser, a stirrer, a thermometer and protected by nitrogen, and react at 60-80° C. for 3-20 hours to obtain the product.

[0114] Among them, p-phenylene diisocyanate, containing R 1 Hydroxyl-terminated hydrocarbons of the group, containing R 2 The molar ratio of hydroxyl-terminated hydrocarbons in the group is 1:(0.5-2):(0.5-2).

[0115] The catalyst dibutyltin dilaurate is 0.3-10 wt% of p-phenylene diisocyanate.

[0116] The solvent is at least one selected from toluene, nitrobenzene, ethyl acetate and dioxane.

[0...

Embodiment 1

[0131] This embodiment 1 provides a kind of black mulching film for cigarettes, which comprises the following components by weight:

[0132] The first linear low density polyethylene: 50 parts;

[0133] The second linear low density polyethylene: 10 parts;

[0134] Black masterbatch: 1 part;

[0135] The melt index of the first linear low density polyethylene is 1 g / 10 min, and the melt index of the second linear low density polyethylene is 0.5 g / 10 min.

[0136] The first linear low density polyethylene (brand name: LL 3301.34) was purchased from ExxonMobil Corporation.

[0137] The second linear low density polyethylene (brand name: LL-3105) was purchased from ExxonMobil Corporation.

[0138] The black masterbatch, in parts by weight, includes the following components: 5 parts of the third linear low density polyethylene, 5 parts of low density polyethylene, 20 parts of carbon black, 0.1 part of BHT immobilized by metal complexes, polypropylene 0.5 parts of wax, 0.4 part...

Embodiment 2

[0156] This embodiment 2 provides a kind of black mulching film for cigarettes, which comprises the following components by weight:

[0157] The first linear low density polyethylene: 90 parts;

[0158] The second linear low density polyethylene: 40 parts;

[0159] Black masterbatch: 10 parts;

[0160] The melt index of the first linear low density polyethylene is 6.8g / 10min, and the melt index of the second linear low density polyethylene is 5g / 10min.

[0161] The first linear low density polyethylene (brand name: LL-8556) was purchased from ExxonMobil Corporation.

[0162] The second linear low density polyethylene (brand name: LL6301RQ) was purchased from ExxonMobil Corporation.

[0163] The black master batch includes the following components in parts by weight: 50 parts of the third linear low-density polyethylene, 50 parts of low-density polyethylene, 90 parts of carbon black, 3 parts of metal complex-supported BHT, polypropylene 15 parts of wax, 12 parts of compound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com