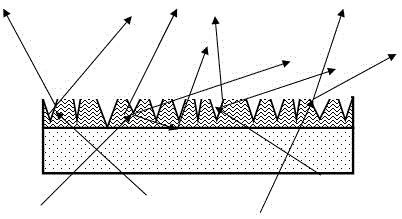

Preparation method of light diffusion sheet with random micro/nano hybrid structure

A technology of light diffusion sheet and hybrid structure, which is applied in the field of light diffusion sheet, can solve the problems of bad influence on product quality, difficult control of uniformity, high technical content, etc., achieve high production and application value, ensure high fidelity, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

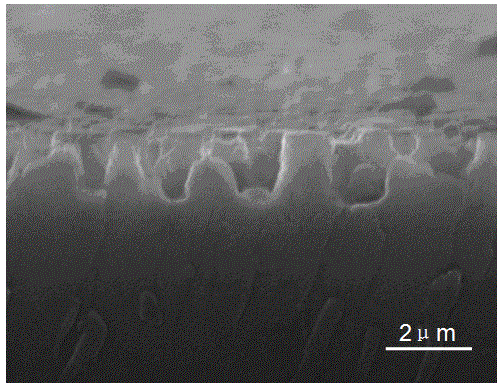

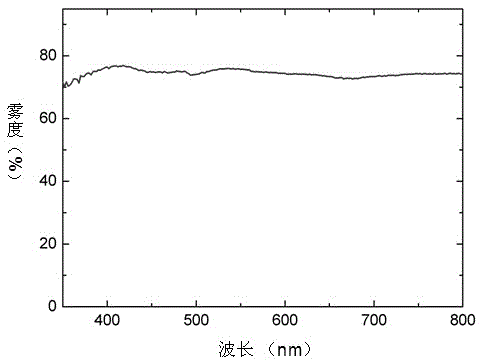

[0021] Example 1: Prepare a light diffusion sheet with a random micro / nano hybrid structure according to the following specific steps

[0022] (1) The quartz glass plate was firstly cleaned by ultrasonic cleaning with acetone for 10 minutes, followed by ultrasonic cleaning with isopropanol for 10 minutes, then ultrasonic cleaning with Semicoclean (trade name) for 10 minutes, then ultrasonic cleaning with ultrapure water for 10 minutes, and then Use the ultraviolet ozone cleaning device to clean the surface for 10 minutes, and finally put the quartz glass plate in a drying oven (Jianqiao, JQ-9030) to dry at 100°C for 5 minutes;

[0023] (2) Move the pretreated quartz glass plate to the vacuum evaporation chamber (Liaoning Juzhi, JZZF-500-Ⅱ), and control the vacuum degree of the vacuum chamber at 2×10 -6 Torr evaporates an 800nm Ag film at an evaporation rate of 0.08nm / sec;

[0024] (3) Move the quartz glass plate with the Ag film into a nitrogen-protected glove box (Lijia, L...

Embodiment 2

[0027] Example 2: Prepare a light diffusion sheet with a random micro / nano hybrid structure according to the following specific steps

[0028] (1) The quartz glass plate was firstly cleaned by ultrasonic cleaning with acetone for 10 minutes, followed by ultrasonic cleaning with isopropanol for 10 minutes, then ultrasonic cleaning with Semicoclean (trade name) for 10 minutes, then ultrasonic cleaning with ultrapure water for 10 minutes, and then Use the ultraviolet ozone cleaning device to clean the surface for 10 minutes, and finally put the quartz glass plate in a drying oven (Jianqiao, JQ-9030) to dry at 100°C for 5 minutes;

[0029] (2) Move the pretreated quartz glass plate to the vacuum evaporation chamber (Liaoning Juzhi, JZZF-500-Ⅱ), and control the vacuum degree of the vacuum chamber at 3×10 -6 Torr evaporates an 800nm Ag film at an evaporation rate of 0.08nm / sec;

[0030] (3) Move the quartz glass plate with the Ag film into a nitrogen-protected glove box (Lijia, L...

Embodiment 3

[0033] Example 3: Prepare a light diffusion sheet with a random micro / nano hybrid structure according to the following specific steps

[0034](1) The quartz glass plate was firstly cleaned by ultrasonic cleaning with acetone for 10 minutes, followed by ultrasonic cleaning with isopropanol for 10 minutes, then ultrasonic cleaning with Semicoclean (trade name) for 10 minutes, then ultrasonic cleaning with ultrapure water for 10 minutes, and then Use the ultraviolet ozone cleaning device to clean the surface for 10 minutes, and finally put the quartz glass plate in a drying oven (Jianqiao, JQ-9030) to dry at 100°C for 5 minutes;

[0035] (2) Move the pretreated quartz glass plate to the vacuum evaporation chamber (Liaoning Juzhi, JZZF-500-Ⅱ), and control the vacuum degree of the vacuum chamber at 4×10 -6 Torr evaporates an 800nm Ag film at an evaporation rate of 0.08nm / sec;

[0036] (3) Move the quartz glass plate with the Ag film into a nitrogen-protected glove box (Lijia, LJ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com