Waterborne polyurethane coating with high surface hardness

A water-based polyurethane, high surface technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of inconspicuous effect, reduce the adhesion of coating film, etc., achieve the effect of reducing VOC, increasing the absorption of small molecules, reducing the easy Gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

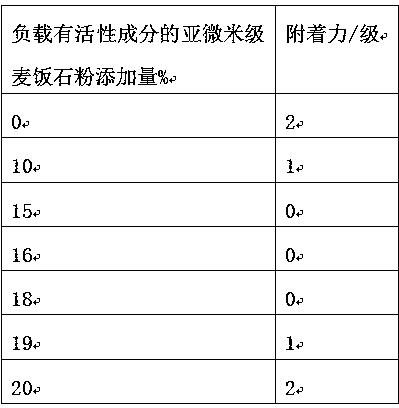

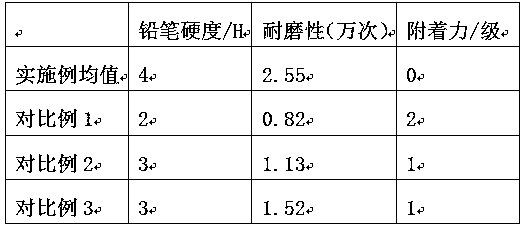

[0020] A water-based polyurethane coating with high surface hardness, the water-based polyurethane coating with high surface hardness contains 15% of its mass of submicron medical stone powder loaded with active ingredients.

[0021] Further, the preparation method of the submicron medical stone powder loaded with active ingredients is as follows:

[0022] (1) Crush the medical stone to make medical stone powder with a particle size of 10 μm, mix the medical stone powder with a diisopropanolamine solution 6 times its mass, stir at 75°C for 70 minutes, and then filter, using deionized Wash with water and dry to constant weight;

[0023] (2) Evenly mix the medical stone powder obtained above with the active ingredient in a mass ratio of 120:30, heat to 112°C under the protection of an inert gas, grind at a speed of 800r / min for 5 hours, and then cool naturally to room temperature, Stand still for 20 minutes, then cool to 0°C, continue to grind for 20 minutes, and naturally retu...

Embodiment 2

[0032] A water-based polyurethane coating with high surface hardness, which contains 18% of its mass of submicron medical stone powder loaded with active ingredients.

[0033] Further, the preparation method of the submicron medical stone powder loaded with active ingredients is as follows:

[0034] (1) Crush the medical stone to make medical stone powder with a particle size of 10 μm, mix the medical stone powder with a diisopropanolamine solution 6 times its mass, stir at 75°C for 70 minutes, and then filter, using deionized Wash with water and dry to constant weight;

[0035] (2) Evenly mix the medical stone powder obtained above with the active ingredient in a mass ratio of 120:36, heat to 116°C under the protection of an inert gas, grind at a speed of 800r / min for 6 hours, and then naturally cool to room temperature, Stand still for 20 minutes, then cool to 0°C, continue to grind for 20 minutes, and naturally return to room temperature to obtain medical stone powder load...

Embodiment 3

[0044] A water-based polyurethane coating with high surface hardness, which contains 16% of its mass of submicron medical stone powder loaded with active ingredients.

[0045] Further, the preparation method of the submicron medical stone powder loaded with active ingredients is as follows:

[0046] (1) Crush the medical stone to make medical stone powder with a particle size of 10 μm, mix the medical stone powder with a diisopropanolamine solution 6 times its mass, stir at 75°C for 70 minutes, and then filter, using deionized Wash with water and dry to constant weight;

[0047] (2) Evenly mix the medical stone powder obtained above with the active ingredient in a mass ratio of 120:30-36, heat to 115°C under the protection of an inert gas, grind at a speed of 800r / min for 5.6 hours, and then naturally cool to room temperature After that, let stand for 20 minutes, then cool to 0°C, continue to grind for 20 minutes, and return to room temperature naturally to obtain medical sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com