Fermented mulberry leaf wine production process

A production process, fermented technology, applied in the field of fermented mulberry leaf wine production process, to achieve the effect of improving the brewing effect, softening the taste and enhancing the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

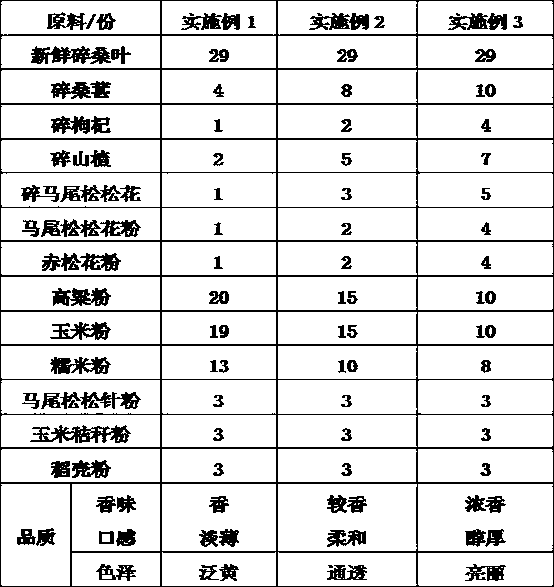

Embodiment 1

[0029] The production technology of fermented mulberry leaf wine comprises the following steps:

[0030] S1. Select fresh mulberry leaves, mulberry, wolfberry, hawthorn, pine flowers, pine pollen, pine pollen, sorghum, corn, glutinous rice raw materials, pine needles, corn stalks, rice husk accessories, yeast , glucoamylase, amylase, Dako powder catalyst;

[0031] S2. Wash sorghum, corn, and glutinous rice with clean water, clean fresh mulberry leaves, mulberry, wolfberry, hawthorn, and masson pine pine flowers; clean masson pine needles, corn stalks, and rice husks with salt water. When cleaning the raw materials, wash the glutinous rice Keep the cleaning solution for later use, use the reserved glutinous rice cleaning solution for preliminary cleaning of fresh mulberry leaves, mulberry, wolfberry, hawthorn, and masson pine flowers, and then use a small amount of flour to mix with fresh mulberry leaves, mulberry, wolfberry, hawthorn, and masson pine flowers for cleaning , an...

Embodiment 2

[0041] The production technology of fermented mulberry leaf wine comprises the following steps:

[0042] S1. Select fresh mulberry leaves, mulberry, wolfberry, hawthorn, pine flowers, pine pollen, pine pollen, sorghum, corn, glutinous rice raw materials, pine needles, corn stalks, rice husk accessories, yeast , glucoamylase, amylase, Dako powder catalyst;

[0043] S2. Wash sorghum, corn, and glutinous rice with clean water, clean fresh mulberry leaves, mulberry, wolfberry, hawthorn, and masson pine pine flowers; clean masson pine needles, corn stalks, and rice husks with salt water. When cleaning the raw materials, wash the glutinous rice Keep the cleaning solution for later use, use the reserved glutinous rice cleaning solution for preliminary cleaning of fresh mulberry leaves, mulberry, wolfberry, hawthorn, and masson pine flowers, and then use a small amount of flour to mix with fresh mulberry leaves, mulberry, wolfberry, hawthorn, and masson pine flowers for cleaning , an...

Embodiment 3

[0053] The production technology of fermented mulberry leaf wine comprises the following steps:

[0054] S1. Select fresh mulberry leaves, mulberry, wolfberry, hawthorn, pine flowers, pine pollen, pine pollen, sorghum, corn, glutinous rice raw materials, pine needles, corn stalks, rice husk accessories, yeast , glucoamylase, amylase, Dako powder catalyst;

[0055] S2. Wash sorghum, corn, and glutinous rice with clean water, clean fresh mulberry leaves, mulberry, wolfberry, hawthorn, and masson pine pine flowers; clean masson pine needles, corn stalks, and rice husks with salt water. When cleaning the raw materials, wash the glutinous rice Keep the cleaning solution for later use, use the reserved glutinous rice cleaning solution for preliminary cleaning of fresh mulberry leaves, mulberry, wolfberry, hawthorn, and masson pine flowers, and then use a small amount of flour to mix with fresh mulberry leaves, mulberry, wolfberry, hawthorn, and masson pine flowers for cleaning , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com