Copper foil perforating machine based on chemical etching, and production technology thereof

A technology of chemical etching and production process, which is applied in the field of chemical etching-based copper foil perforator and its production process, which can solve the problems of poor quality of copper foil finished products and low work efficiency, and achieve a small degree of damage to mechanical properties, The production process is environmentally friendly and the effect of improving the quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

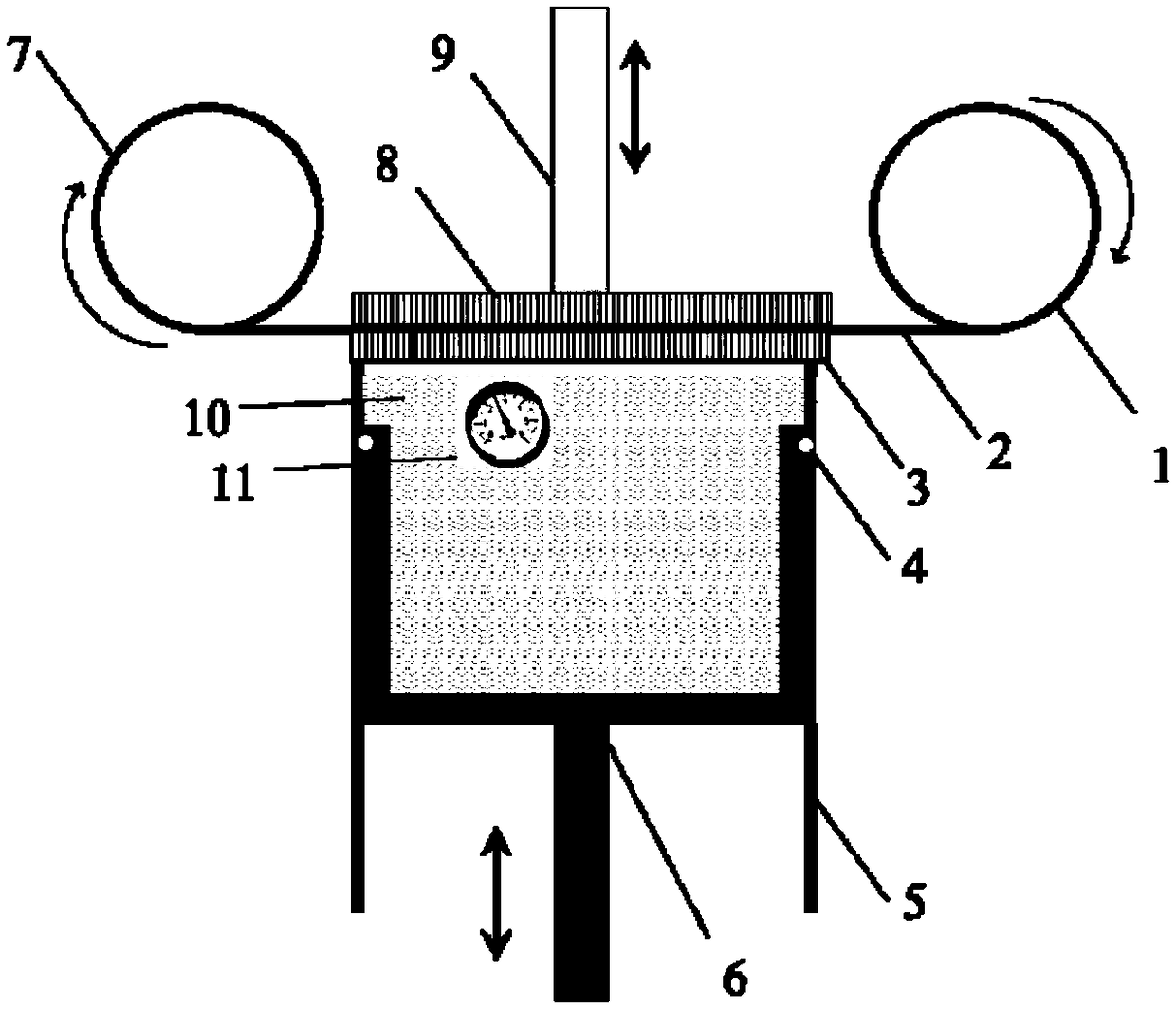

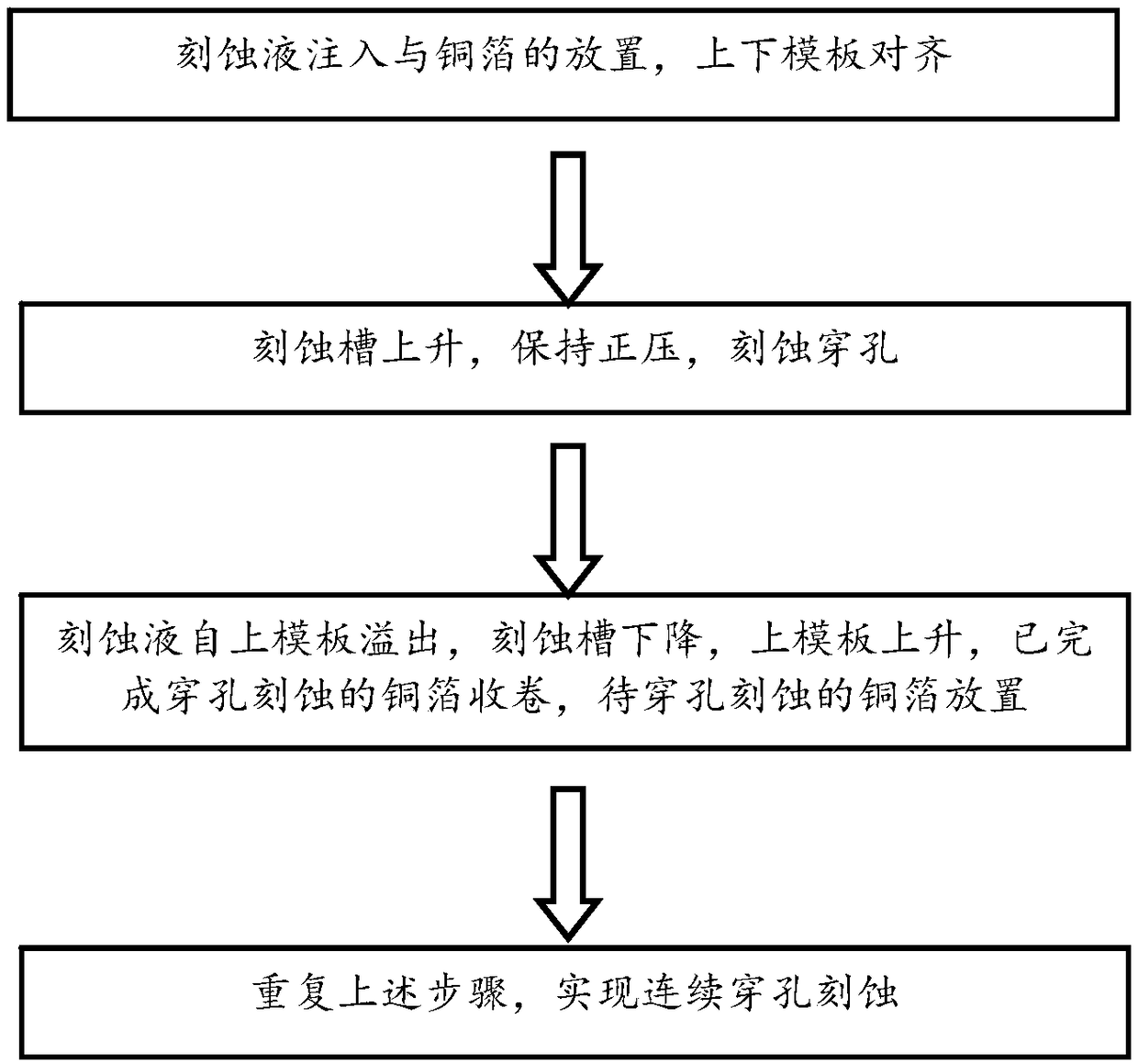

Method used

Image

Examples

Embodiment 1

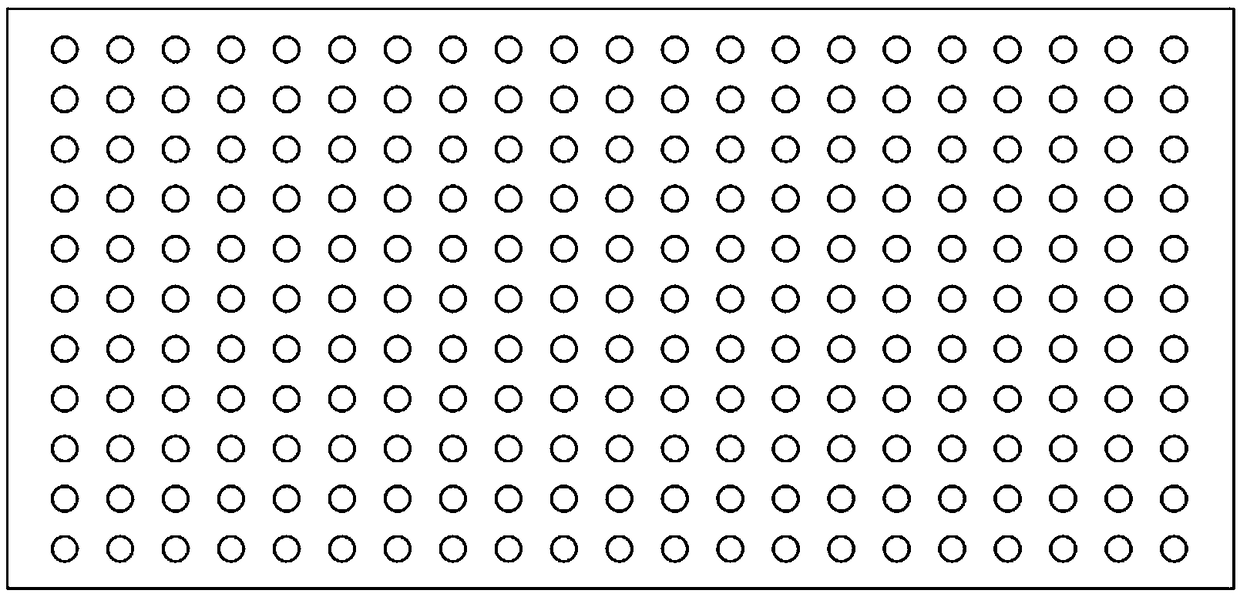

[0029] FeCl with a concentration of 20wt% was injected into the etching groove 3 Etching liquid and make the liquid level exceed the upper edge of the etching tank, place the lower template on the upper edge of the puncher casing, spread the copper foil with a thickness of 6 μm on the upper surface of the lower template, press the upper template on the top of the copper foil, and the upper and lower templates Align the holes in the upper and lower templates with dowels. The upper and lower templates are stainless steel plates with a thickness of 1 mm, and the surface roughness is 1 μm. The template contains circular holes with a diameter of 50 μm. The circular holes are distributed in a rectangular shape, and the distance between the centers of the holes is 80 μm. image 3 shown. Push the etching tank up so that the liquid level of the etching solution rises and contacts the copper foil. The internal pressure of the etching tank is kept at 10Pa. When the etching solution over...

Embodiment 2

[0031] FeCl with a concentration of 20wt% was injected into the etching groove 3 Etching liquid and make the liquid level exceed the upper edge of the etching tank, place the lower template on the upper edge of the piercer casing, spread the copper foil with a thickness of 80 μm on the upper surface of the lower template, press the upper template on the copper foil, and the upper and lower templates Align the holes in the upper and lower templates with dowels. The upper and lower templates are stainless steel plates with a thickness of 5 mm, and the surface roughness is 2 μm. The template contains round holes with a diameter of 1000 μm, which are distributed in a honeycomb shape, and the center spacing of the holes is 1200 μm. Push the etching tank up so that the liquid level of the etching solution rises and contacts the copper foil. The internal pressure of the etching tank is kept at 100 Pa. When the etching solution overflows from the hole of the upper template, lower the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com