Heat accumulating type heat pump steam engine and steam generating method

A steam engine and thermal storage technology, which is applied in the field of heat storage heat pump steam engines for peak shifting and valley filling, can solve the problems of system failure and circulating water temperature cannot be cooled, and achieve high heat exchange efficiency, good environmental protection benefits, and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

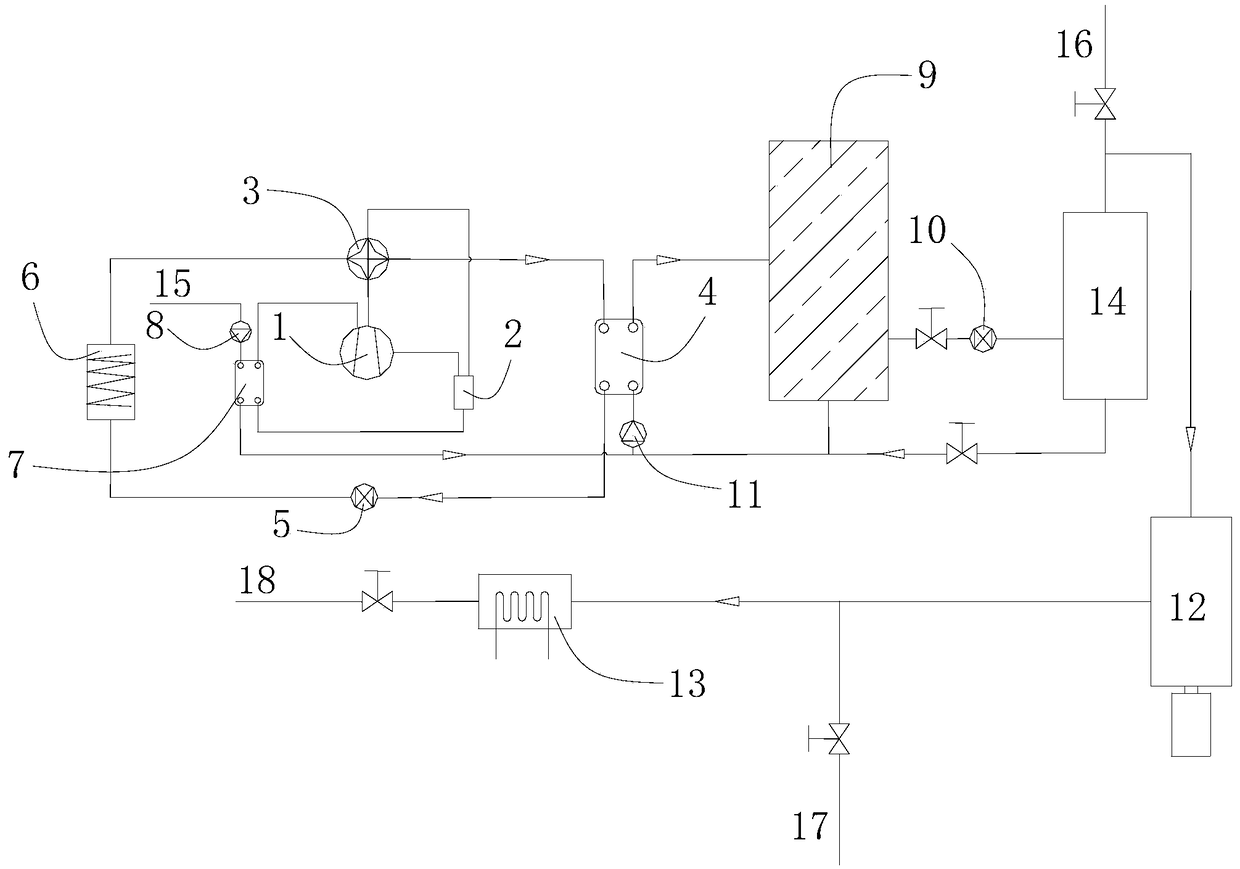

[0022] refer to figure 1 , is a regenerative heat pump steam engine, including a high-temperature heat pump circulation system, a heat storage system, a steam reheating system and several shut-off valves; the high-temperature heat pump circulation system includes a refrigerant compressor 1, an oil separator 2, a four-way valve 3, a plate type Cooler 4, expansion valve 5, evaporator 6, feed water pump 8 and circulating water pump 11; the hot side inlet at the lower end of oil cooler 7 communicates with the high temperature oil outlet at the lower end of oil separator 2, and the hot side outlet at the upper end of oil cooler 7 It is connected with the refrigerant compressor 1 to form an oil circulation loop; the upper cold side inlet of the oil cooler 7 is connected to the tap water inlet 15 through the feed water pump 8, and the lower cold side outlet of the oil cooler 7 is connected to the plate cooler 4 through the circulating water pump 11 The inlet of the water side is conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap