Standing vortex type smoke inner circulation low-nitrogen combustor

A low-nitrogen burner and burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of large construction costs and operating costs, and achieve low cost, increased circulation, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

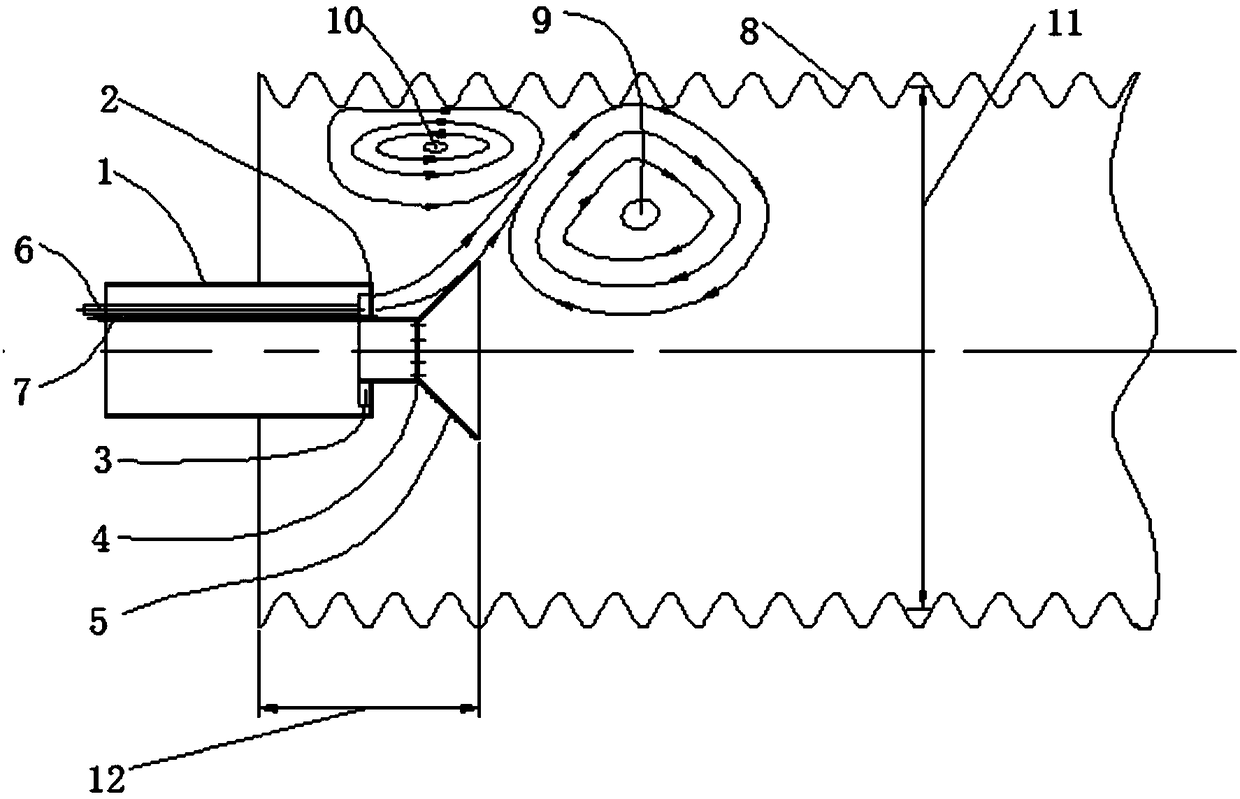

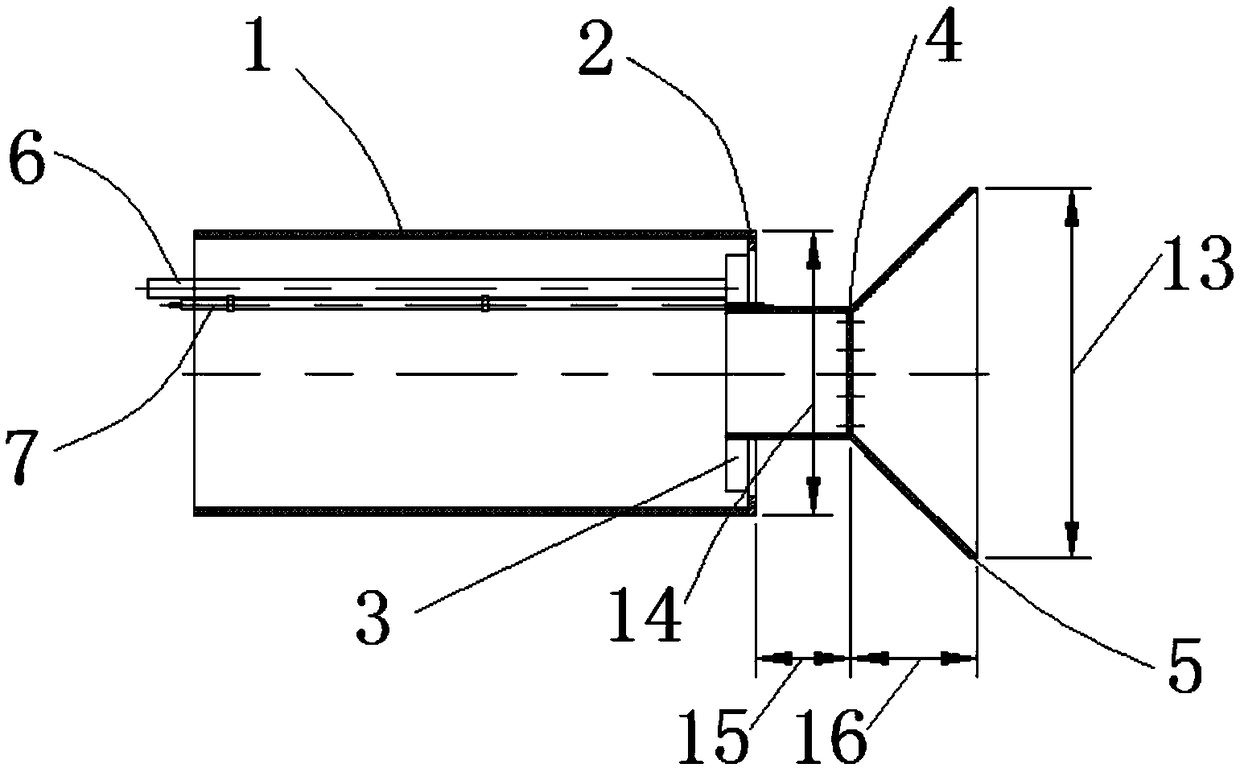

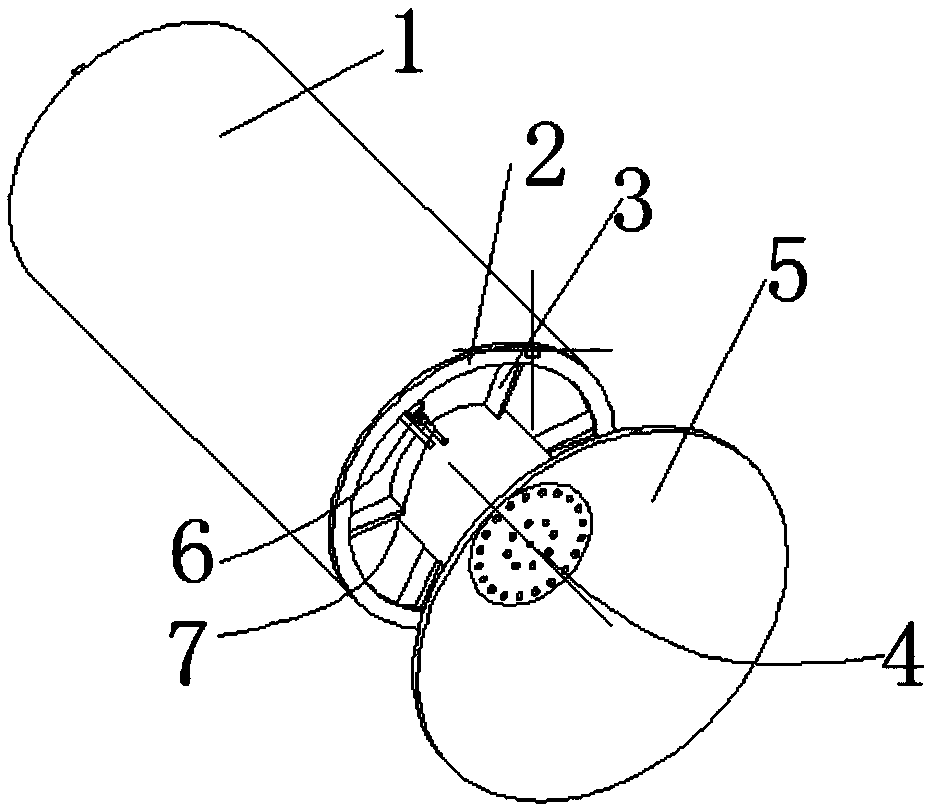

[0025] Such as figure 1 As shown, the embodiment of the present invention is mainly composed of a burner inlet pipe 1, a flow rate adjusting ring 2, a central purge plate 4, and a vortex control section 5; the burner should extend into the furnace 8 of an industrial furnace or a boiler to ensure a certain combustion The extension length of the burner is 12; the central purge plate 4 is welded on the vortex control section 5, the vortex control section 5 is welded to the installation piece 3, and the installation piece 3 is welded to the burner inlet pipe 1, so that the vortex control section 5 is fixed on the On the burner inlet pipe 1; the ignition fuel pipe 6 is fixed on the burner inlet pipe 1 through connecting rods, etc., the ignition electrode 7 is fixed on the ignition fuel pipe 6 by screws, and the ignition fuel pipe 6 and the ignition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com