Centrifugal micro-fluidic detector with flip type temperature control chamber

A detector and microfluidic technology, applied in the field of centrifugal microfluidic detectors, can solve problems such as accumulation, mechanical damage, and inability to integrate detection and analysis functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

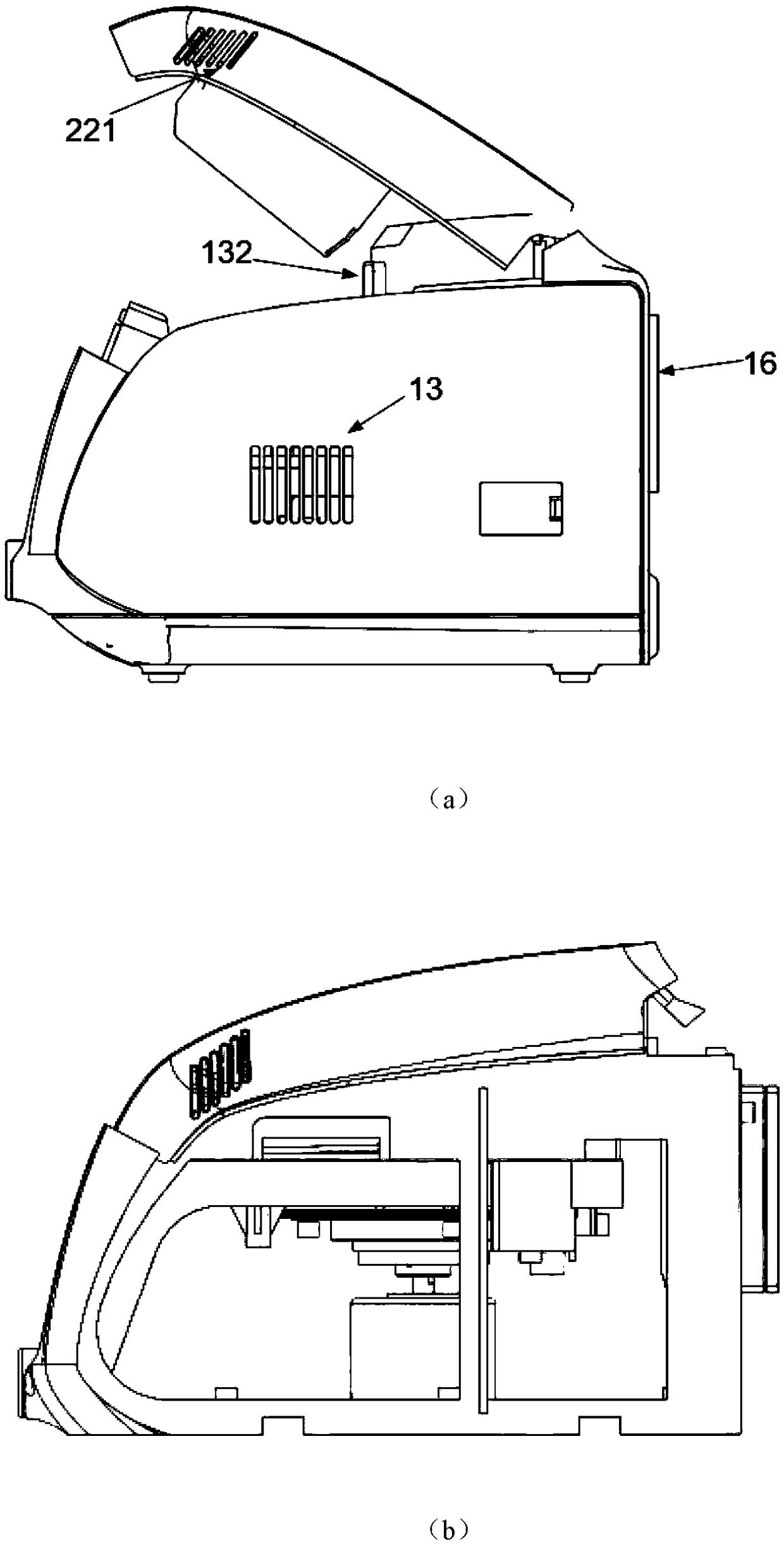

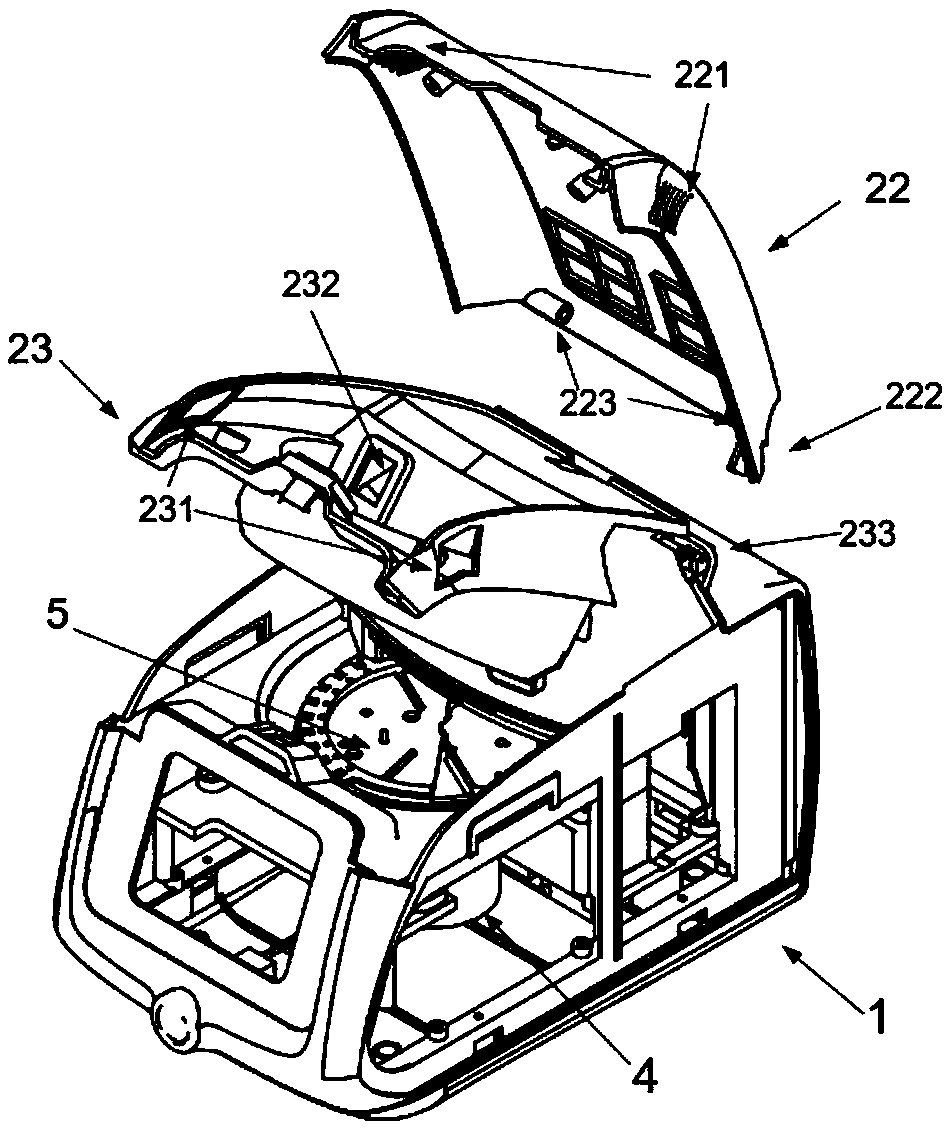

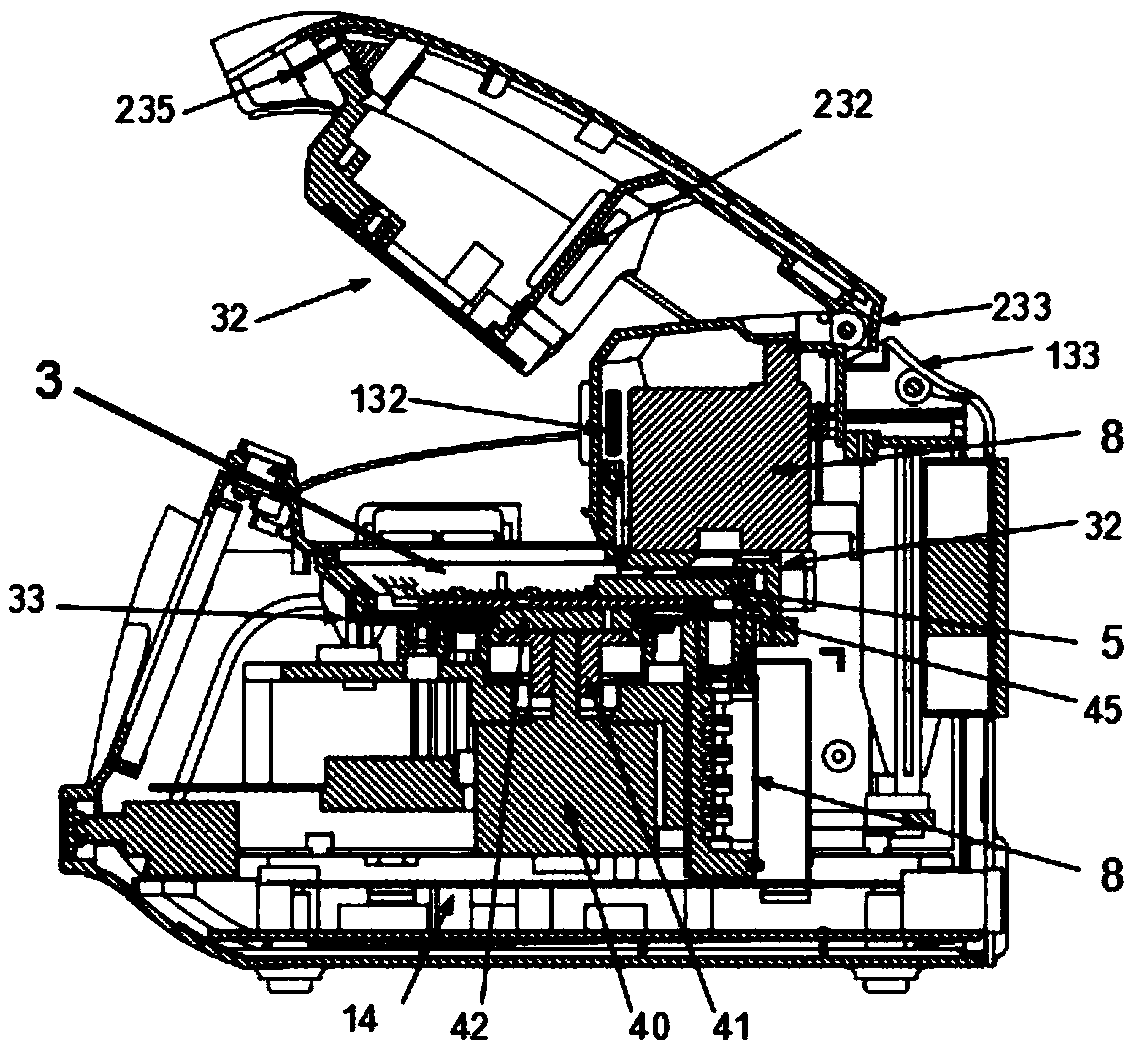

[0077] The centrifugal microfluidic detector provided by the present invention includes a detector cavity 1, an upper cover 2, a temperature control chamber 3 disposed in the detector cavity 1, a rotating motor assembly 4, an air outlet fan 6 and a detector assembly 8.

[0078]Wherein, the temperature control chamber 3 is an airtight chamber formed by the upper end cover 32, the cylinder body and the lower end cover 33 in order from top to bottom. The diameter-to-height ratio of the cylinder body is in the range of 6-16, and the height The range is 7-12 mm, and the diameter of the cylinder is 8-11 cm, which is a flat chamber. The outer surface of the upper end cover 32 is attached with a thin temperature controller (not marked in the figure) with the same shape and size, and the outer surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com