A lens position adjustment mechanism for an optical system

A technology for adjusting mechanisms and optical systems, applied in optics, optical components, instruments, etc., can solve problems that are difficult to meet, difficult to clean, and easily damaged optical systems, and achieve the effects of accurate relative position, simple adjustment operation, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

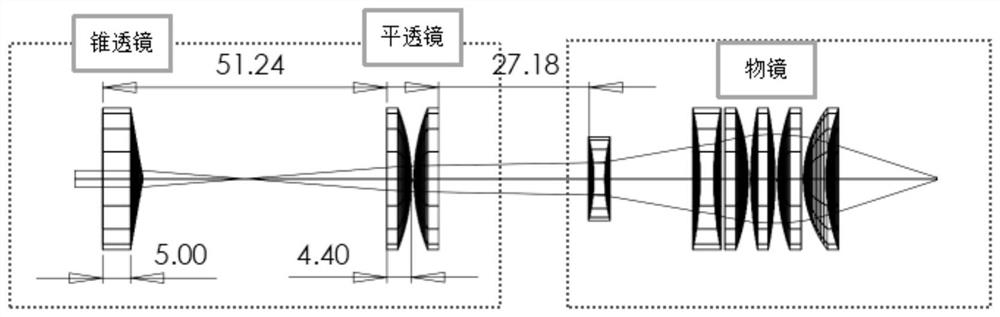

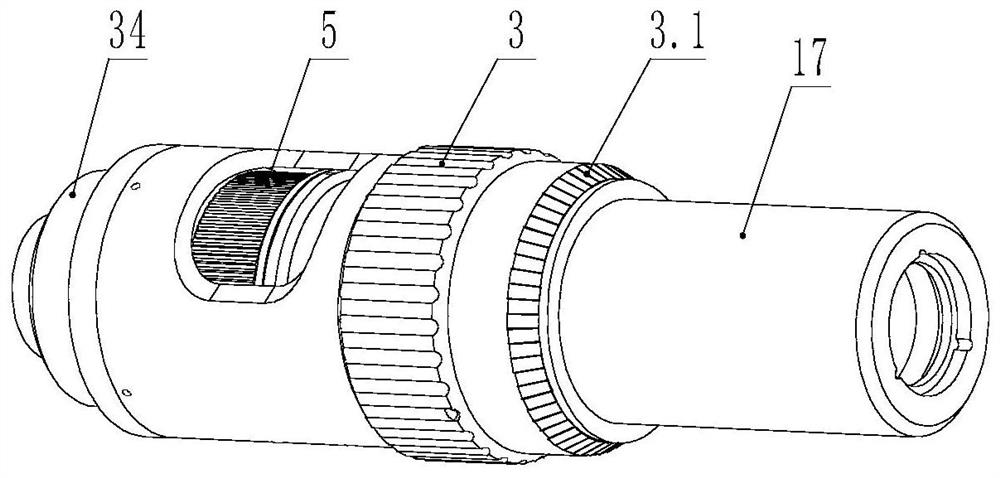

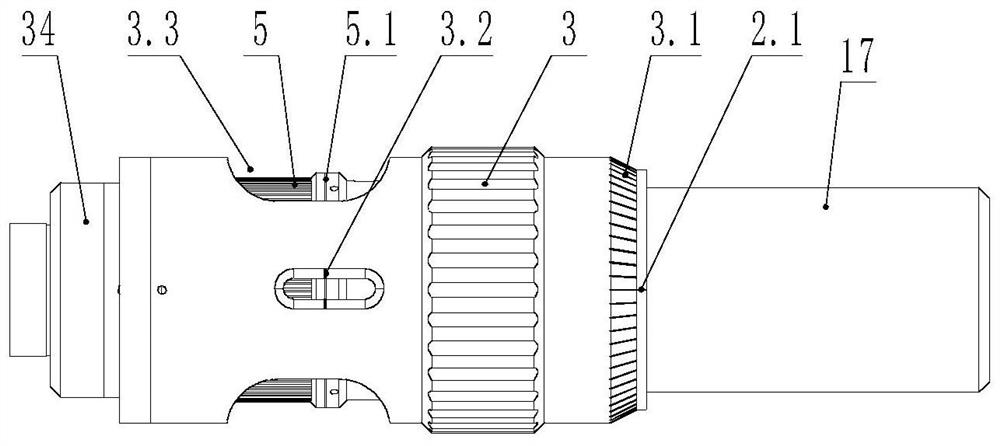

[0030] Such as Figure 2-5 Shown, the present invention comprises objective lens 1, the plano lens holder 4 of fixed plano-convex lens 7, the axicon lens holder 6 of fixed axicon lens 8, outer sleeve 3 and axicon lens adjustment sleeve 5, described objective lens 1, plano-convex lens 7 and the axicon lens 8 are coaxially arranged in turn; one end of the outer sleeve 3 is connected to the axial limit of the end of the objective lens 1, the inner wall of the outer sleeve 3 is threaded with the outer wall of the flat lens holder 4, and the flat lens holder 4 A first cavity 39 is provided between one end and the objective lens 1, the other end of the flat lens holder 4 is fixedly connected with one end of the axicon lens adjustment sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com