Experiment for simulating whole process of fully-mechanized coal mining of underground coal mining roadway and teaching system thereof

A teaching system and whole-process technology, applied in the direction of simulators, teaching models, space navigation conditions simulation devices, etc., can solve the problem of high cutting cost of coal shearers, unsatisfactory students, little research on coal shearers and supports, etc. problems, to achieve the effect of saving internship funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

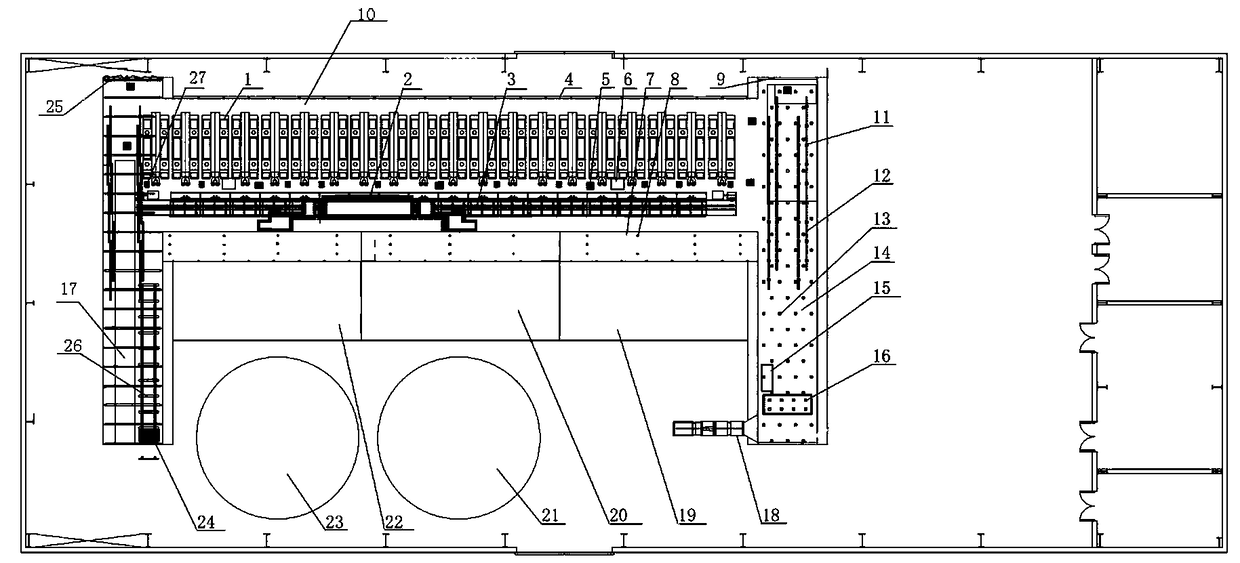

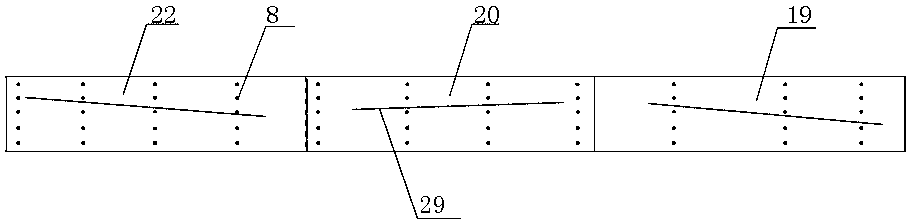

[0023] Using the experiment and teaching system of the present invention, the fully mechanized mining face can be built to the ground, which solves the hidden safety hazards of students in underground practice. The model is MG160 / 375-WD electric traction shearer 1, the model is SGZ630 / 150 scraper conveyor 3 and model ZY6800 / 14 / 31 hydraulic support 1 as supporting equipment behind fully mechanized mining face. Simultaneously construct the upper and lower channels 14 and 17, and the entire simulated roadway 10 is completely enclosed to truly reproduce the whole process of coal mining to meet the needs of students' practice; install various sensors, such as gas sensors 5, dust detection controller 6, Pressure and vibration sensor 8; installation of visual equipment, such as a demonstration screen and a falling demonstration area 25 can be used to meet the scientific research needs of teachers. In addition to research and student internships, training for electric traction shearer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com