Self-repairing conductive structure and preparation method thereof

A conductive structure and self-repairing technology, which is applied to equipment for manufacturing conductive/semiconductive layers, printed circuit manufacturing, cable/conductor manufacturing, etc., can solve problems such as abnormal signals, cracks in conductive layers, and shortened life of conductive structures. Achieve the effect of avoiding abnormalities and improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

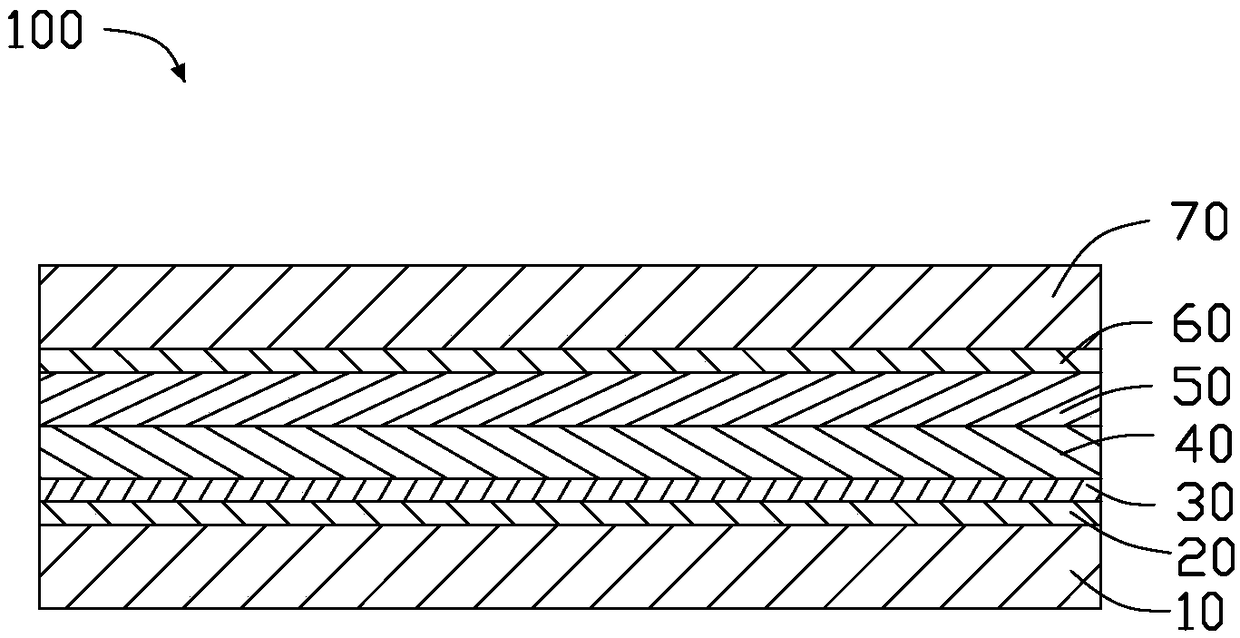

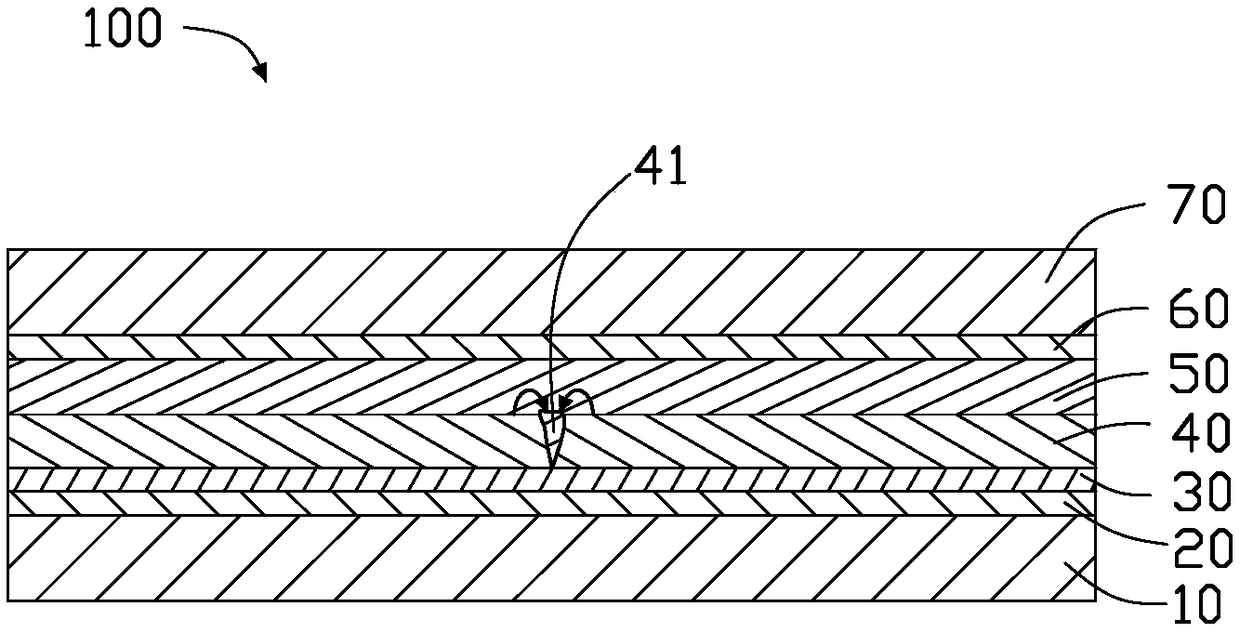

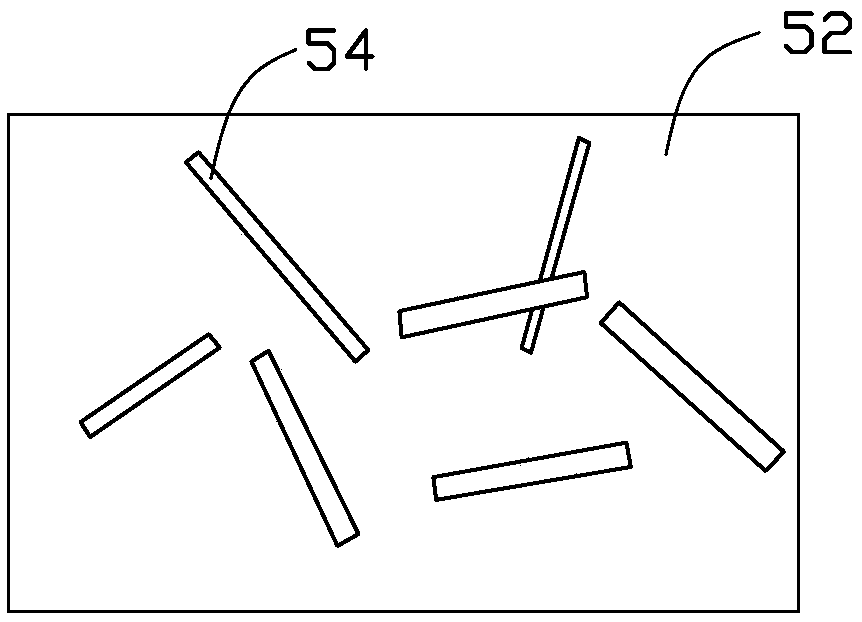

[0026] Such as Figure 1A As shown, a self-healing conductive structure 100 according to an embodiment of the present invention includes a substrate layer 10, a first adhesive layer 20, a heating layer 30, a conductive layer 40, a self-healing layer 50, a second adhesive layer 60, and a cover layer 70 . The heating layer 30 is bonded to a surface of the substrate layer 10 through the first adhesive layer 20 . The covering layer 70 is bonded to the self-healing layer 50 through the second adhesive layer 60 . One surface of the conductive layer 40 covers the self-healing layer 50 , and the other surface covers the heating layer 30 .

[0027] In one embodiment, the self-healing conductive structure 100 may be a flexible circuit board. Wherein, the material of the substrate layer 10 and the material of the cover layer 70 can be polycarbonate (polycarbonate, PC), polymethyl methacrylate (polymericmethyl methacrylate, PMMA), polyethylene terephthalate (polyethylene glycolterephtha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com