Flexible circuit board full-automatic wire stripping, terminal pressing and shell insertion method and device

A fully automatic, wire-stripping technology, applied in circuit/collector parts, assembly/disassembly of contacts, electrical components, etc. Problems such as the insufficiency of the terminal shell to achieve the effect of improving the quality of the shell, reducing the defective rate of the shell, and improving the quality of the assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

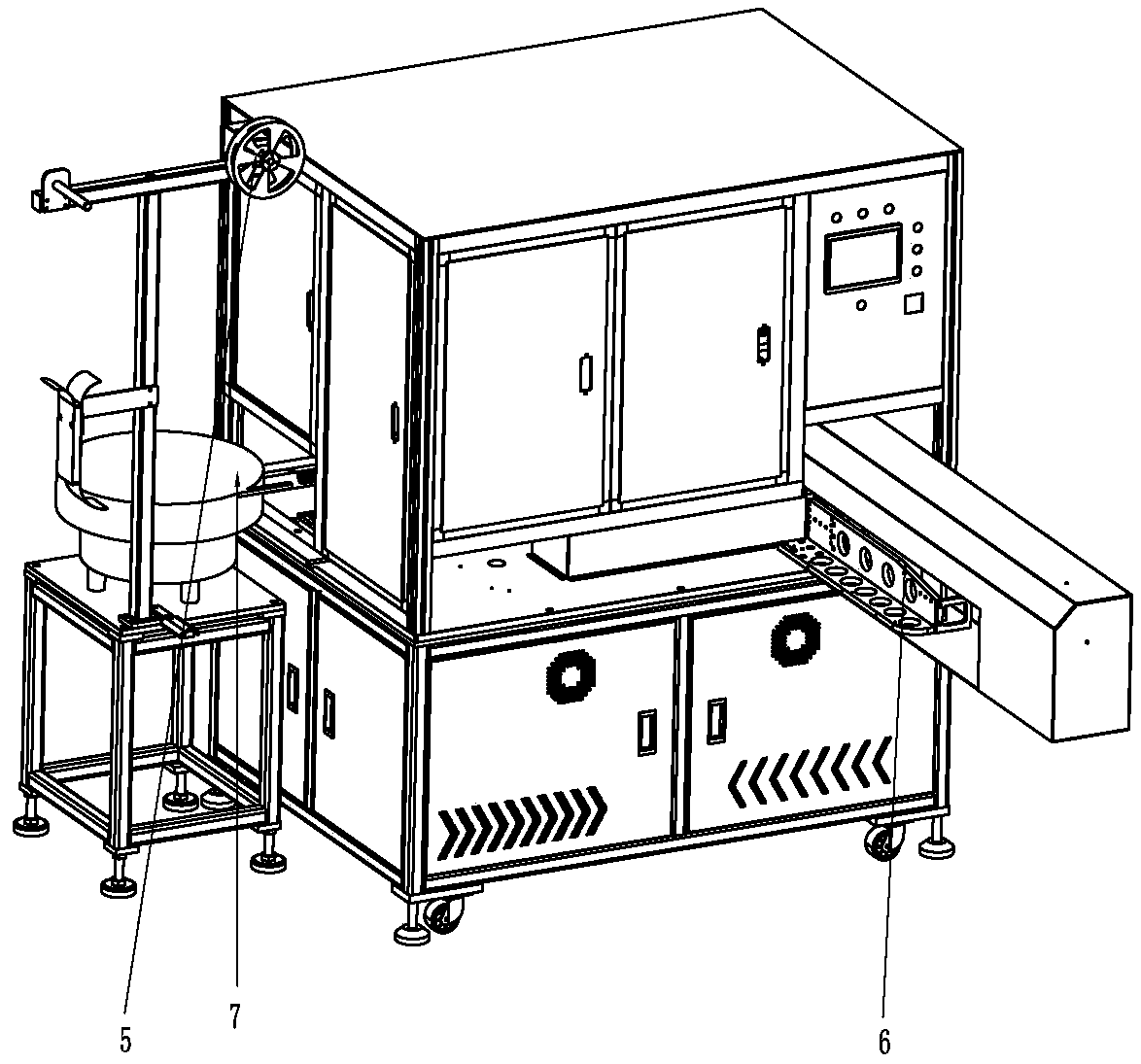

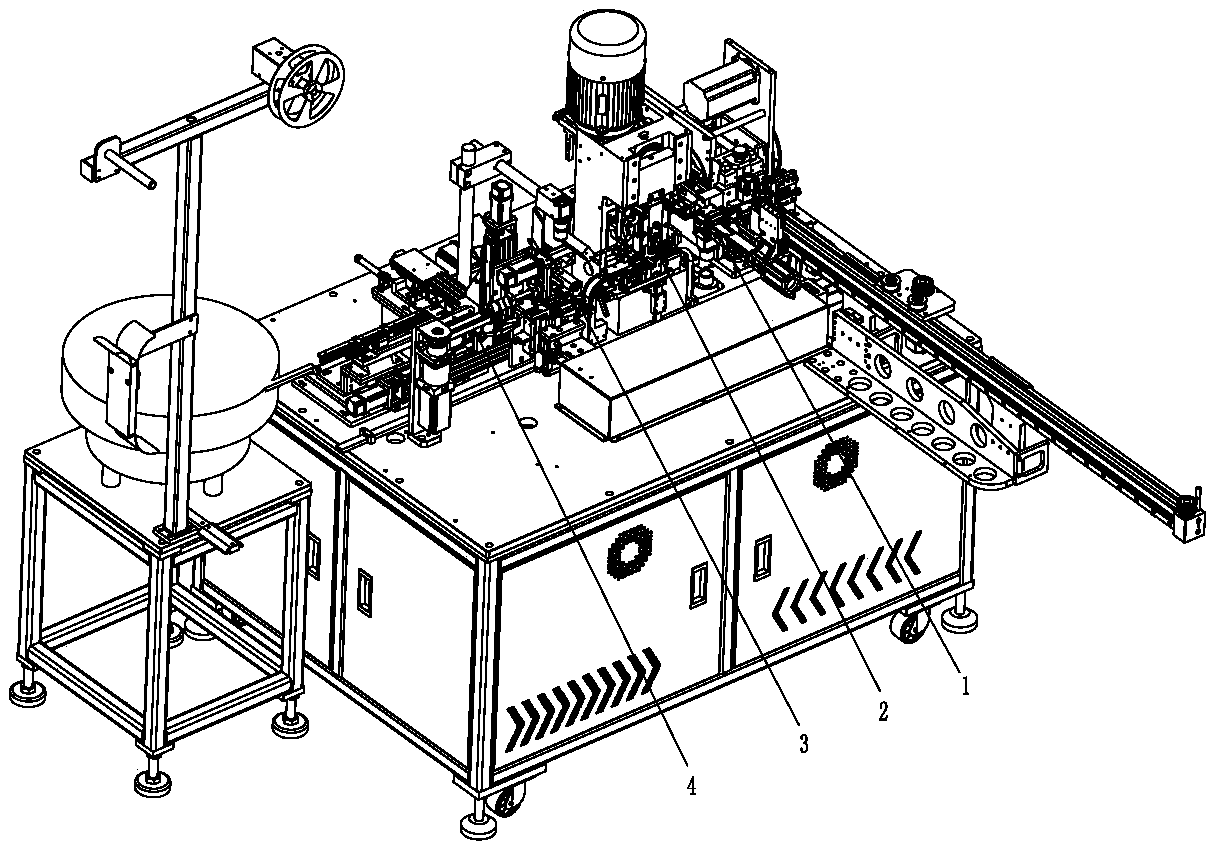

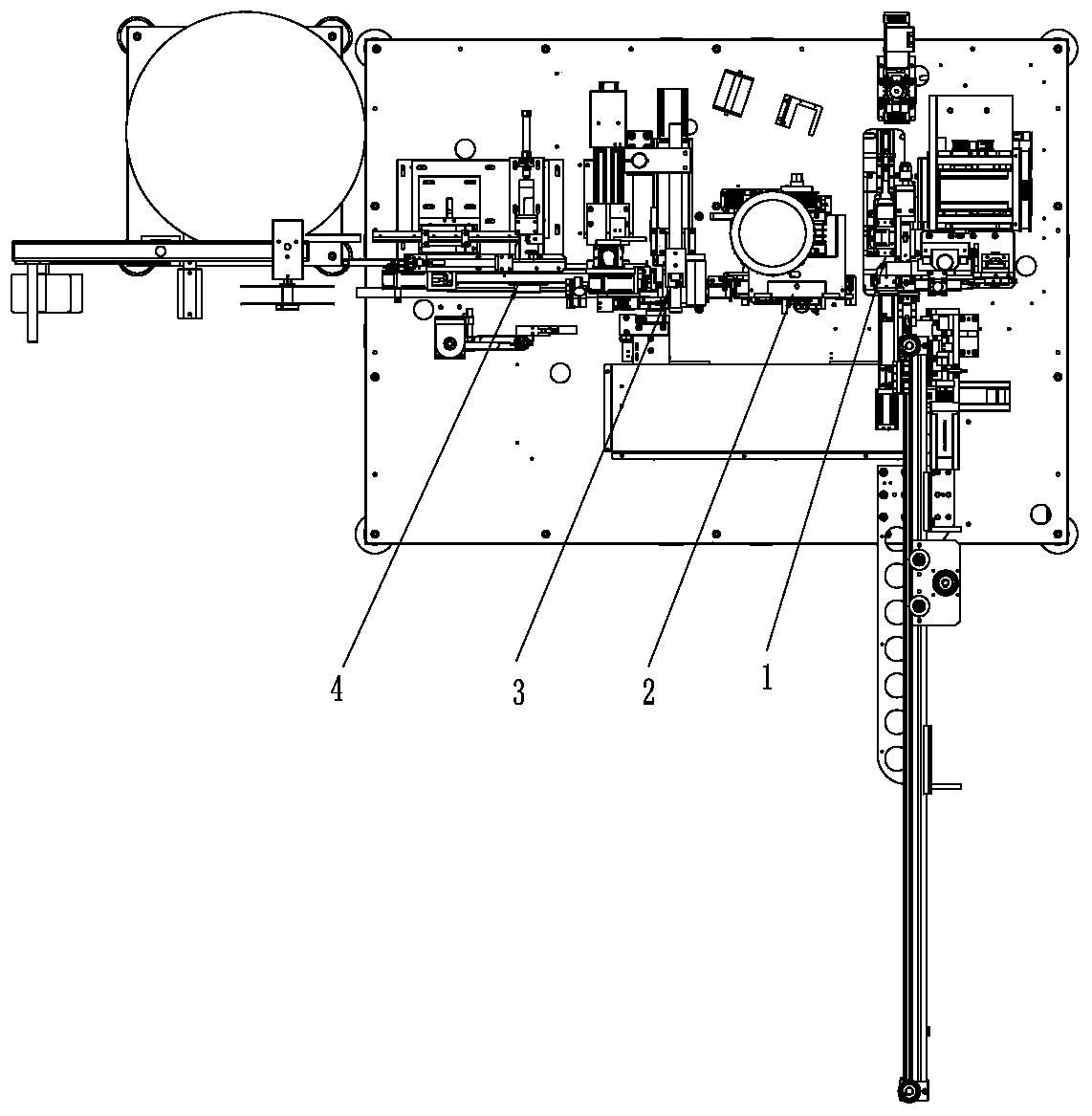

[0042] Please refer to Figure 1 to Figure 23 As shown, it shows the specific structure of the embodiment of the present invention.

[0043] A method for fully automatic wire stripping, crimping, and shell insertion of cables, which sequentially includes the steps of stripping, crimping, splitting, and inserting; And, the corresponding crimping device (integrated interlocking crimping module 2), branching device 3, housing device 4, other links (for example: stripping device 1, terminal strip supply end 5, cable supply end 6. The rubber shell supply end 7) can be realized by conventional technology, and there is no limitation here.

[0044] Next, according to the process, the three links of pressure end, branch line and socket are introduced one by one:

[0045] Please refer to Figures 1 to 3 ,as well as, Figures 20 to 23 As shown, it shows the design structure of the crimping device and the crimping method:

[0046] The end-feeding device 30 is a bottom-feeding type en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com