Polishing pad dresser and manufacturing method thereof

A manufacturing method and dresser technology, which are applied in the directions of manufacturing tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., to achieve the effect of reducing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

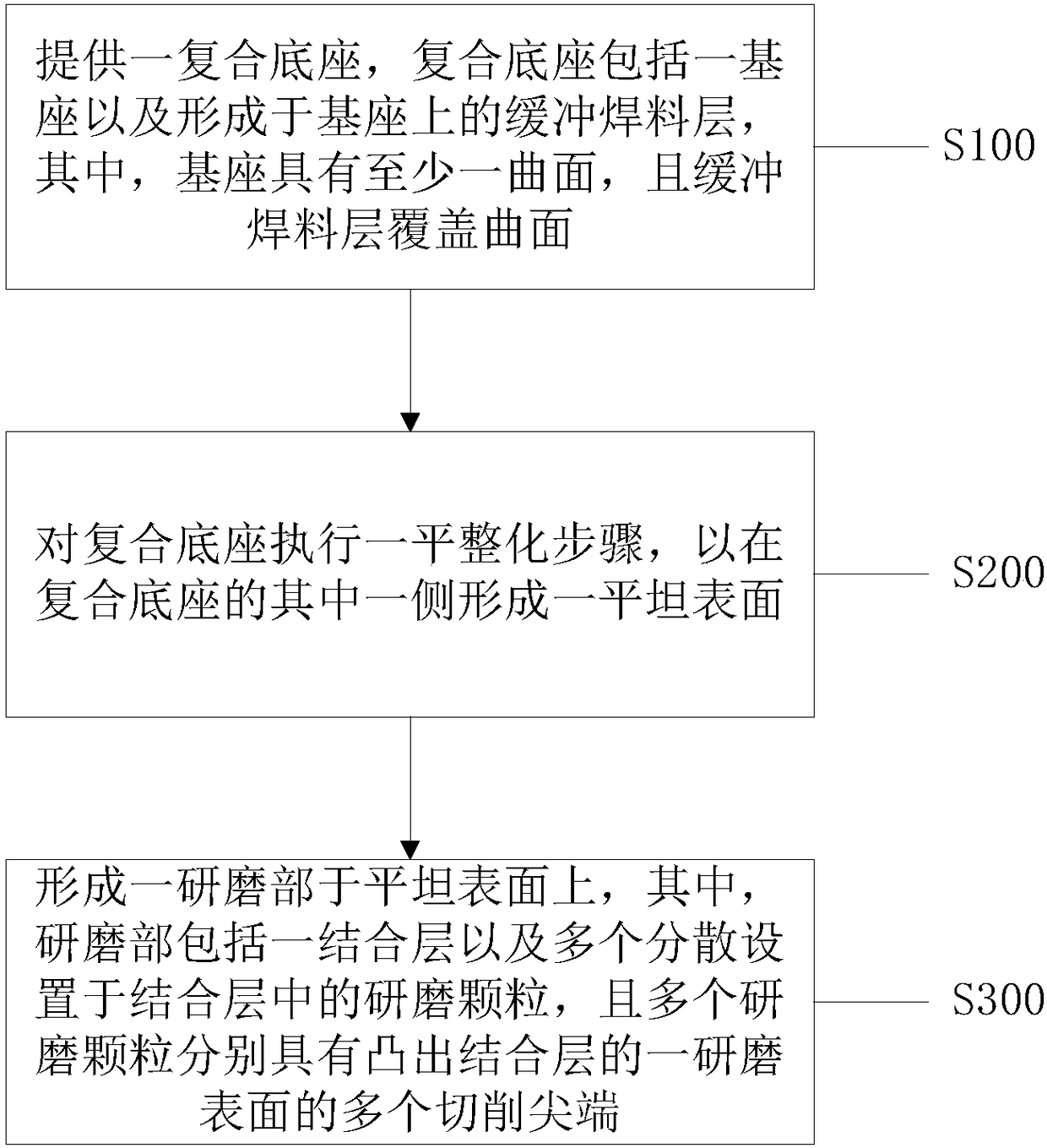

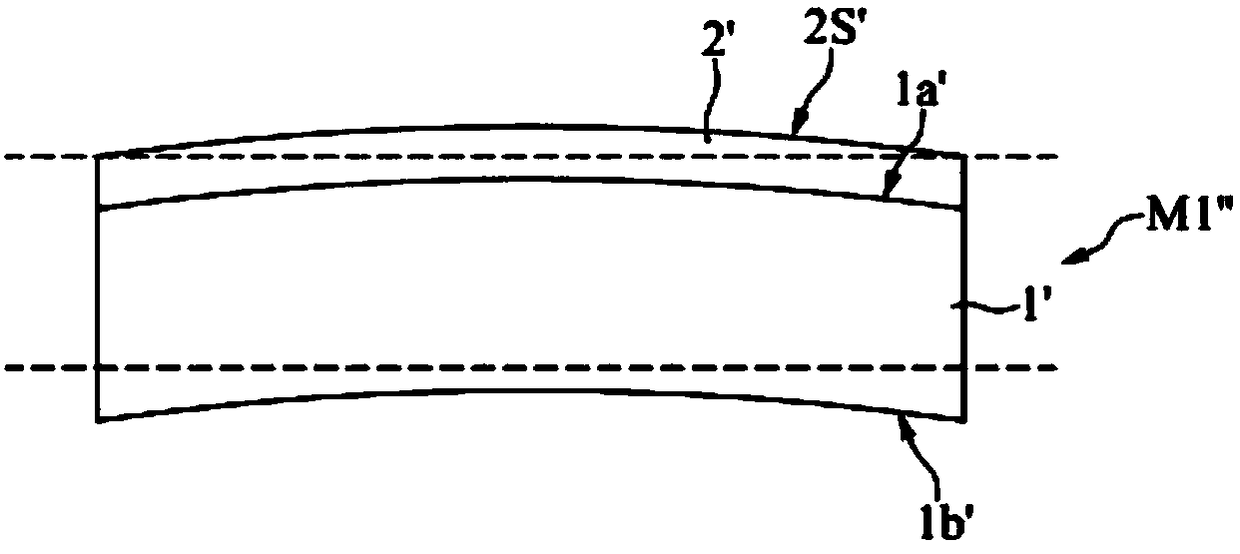

[0030] see figure 1 , Figure 2A to Figure 2D . figure 1 It is a flowchart of a manufacturing method of a polishing pad dresser according to one embodiment of the present invention. Figures 2A to 2D The polishing pad dresser of one embodiment of the present invention is respectively in figure 1 Schematic cross-sections of each step.

[0031] Such as figure 1 As shown, in step S100 , a composite base is provided, the composite base includes a base and a buffer solder layer formed on the base, wherein the base has at least one curved surface, and the buffer solder layer covers the curved surface.

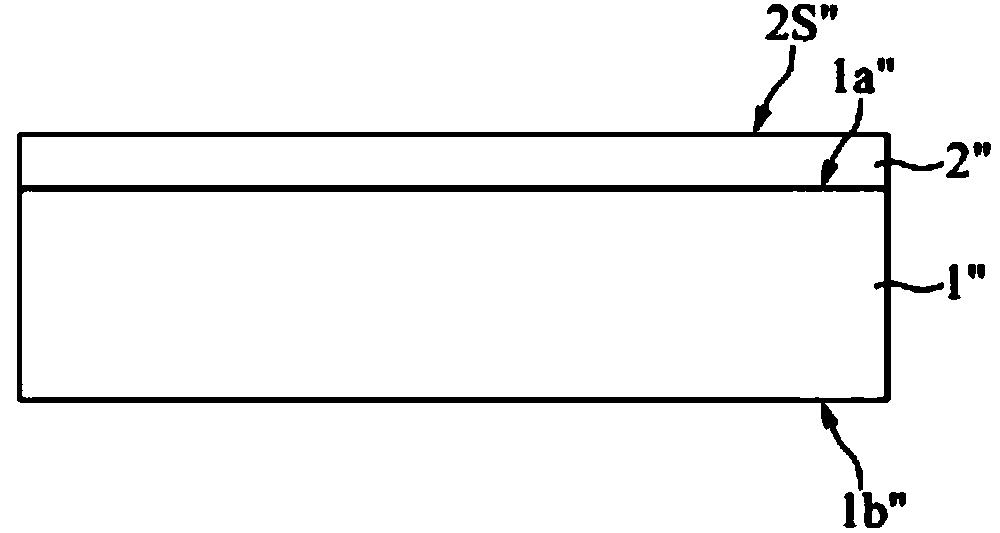

[0032] Please refer to Figure 2A and Figure 2B , showing the process of providing the composite base. Specifically, as Figure 2A As shown, a buffer solder 2" is first formed on an initial base 1".

[0033] The material of the initial base 1" can be iron, molybdenum, tungsten, stainless steel, invar or nickel-based superalloy. In one embodiment, the material of the initial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com