A Construction Technology of Bilateral Composite Beam Prefabricated Post-tensioned Prestressed Assembly Pavement

A construction technology and composite beam technology, applied in roads, roads, road reinforcements, etc., can solve the problems of low road bearing capacity, long construction period, low level of road engineering assembly construction, etc., to reduce traffic inconvenience and noise Influence, improve road bearing capacity, improve the effect of efficient construction level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

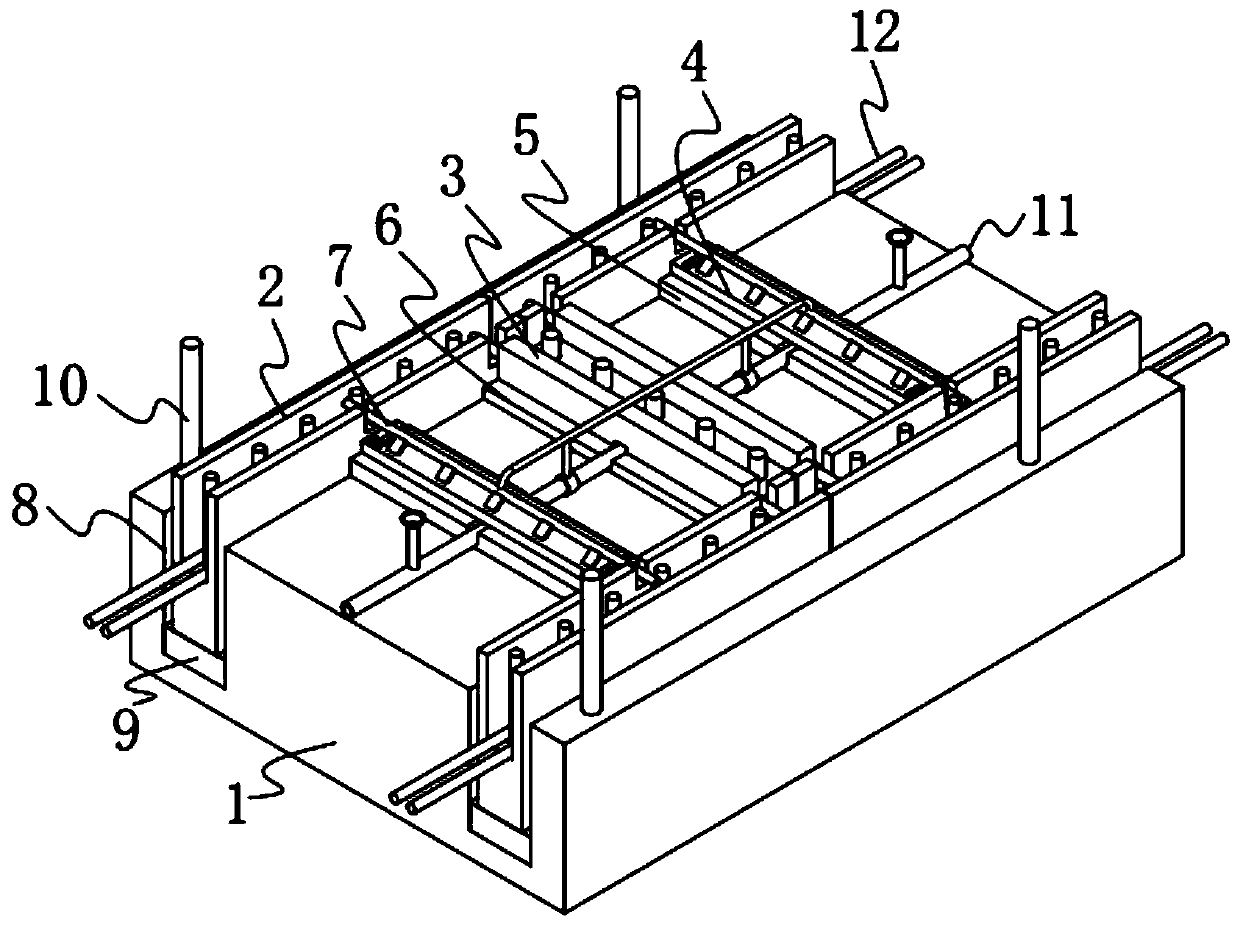

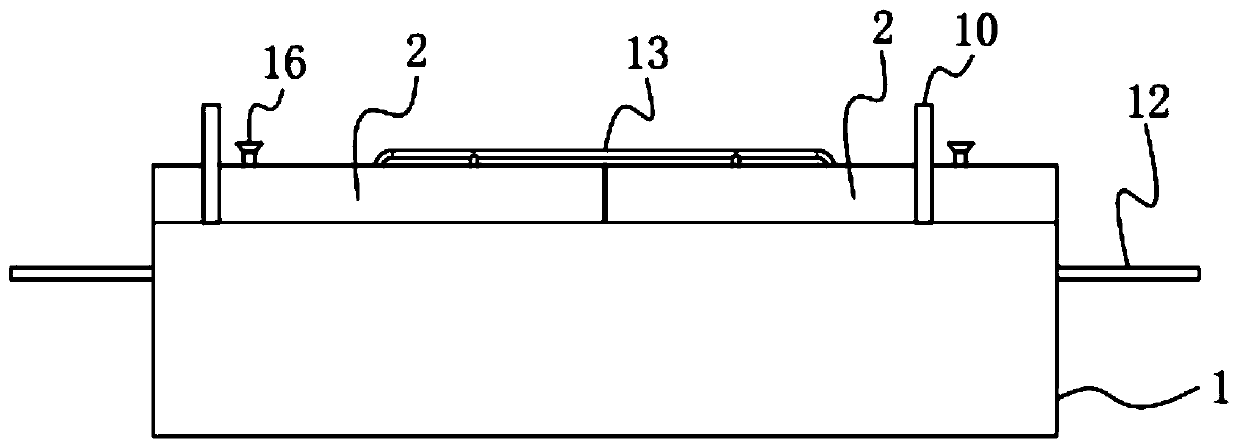

[0048] A construction technology for prefabricated post-tensioned prestressed assembly pavement of double-sided composite beams, comprising the following steps:

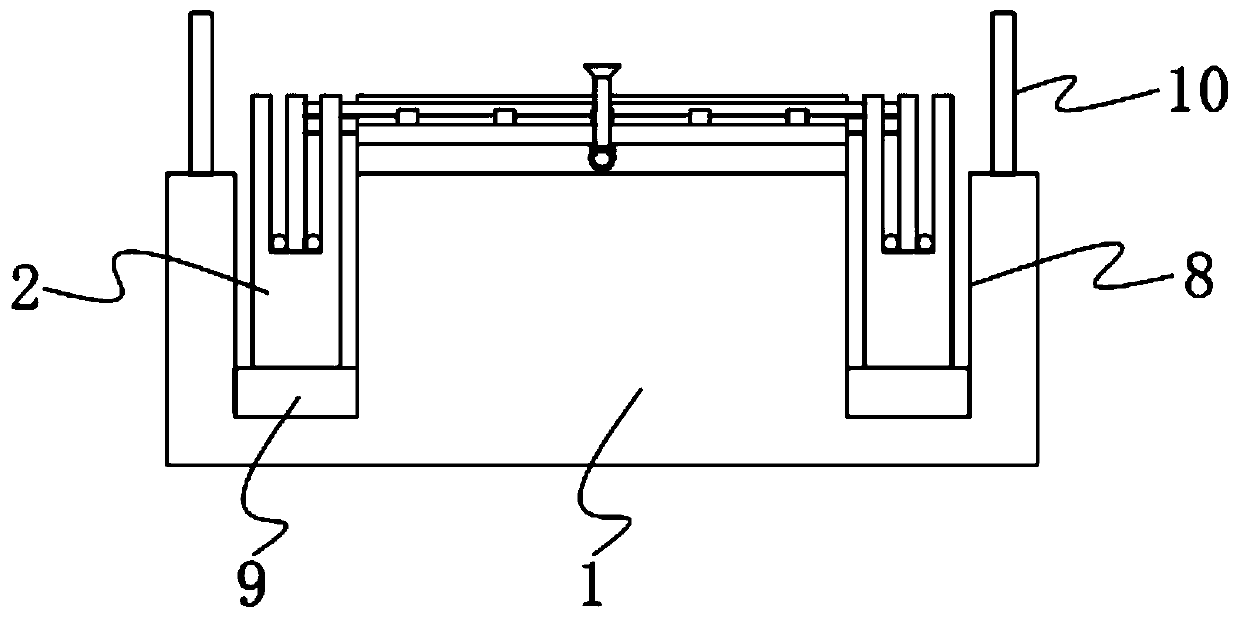

[0049] The first step, subgrade 1 processing

[0050] In order to meet the subsequent on-site hoisting of laminated slab 4 and longitudinal laminated beam 2, trenches 8 for installing longitudinal laminated beams 2 are excavated on both sides of the upper part of subgrade 1 in advance, and the excavation depth of trench 8 is determined according to the design elevation , the distance between the grooves 8 on both sides shall be excavated according to the design standard, and the excavation width of the groove 8 shall be 90-110 mm larger than the width of the longitudinal laminated beam 2, and a layer of 90 mm shall be poured at the inner bottom of the groove 8 - 110mm thick first concrete cushion 9;

[0051] The second step, longitudinal laminated beam 2 hoisting

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com