Functionally recoverable assembled beam-column connection joint and construction method

A beam-column connection and prefabricated technology, applied in construction, building structure, etc., can solve the problems of single purpose, difficult to achieve high-performance structural goals, etc., to improve welding quality, avoid brittle failure, and ensure strength and bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

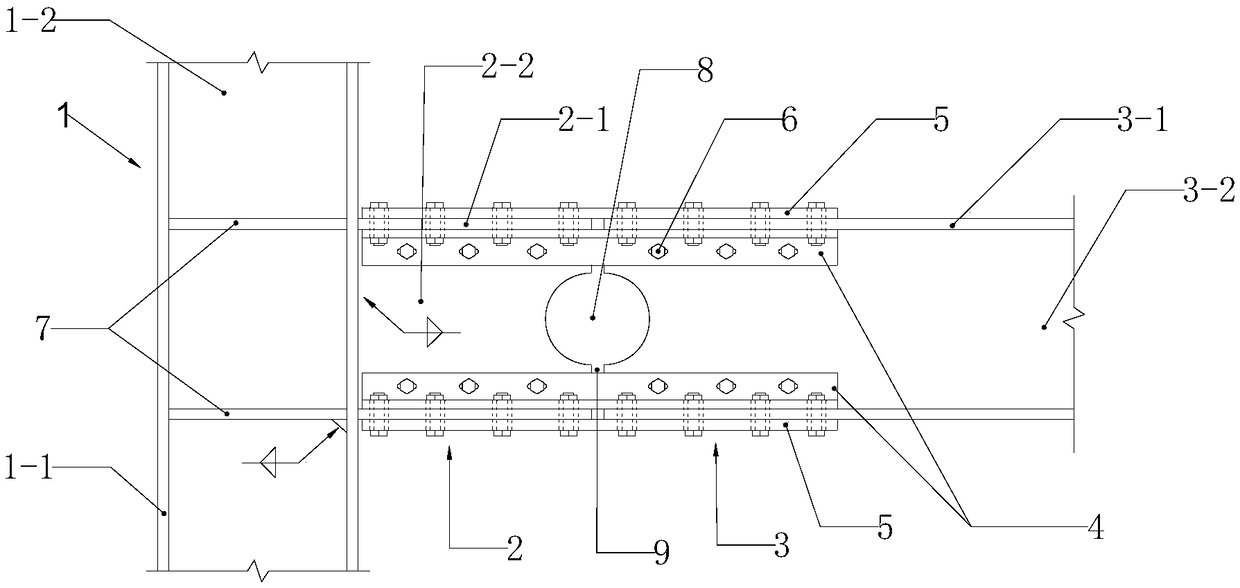

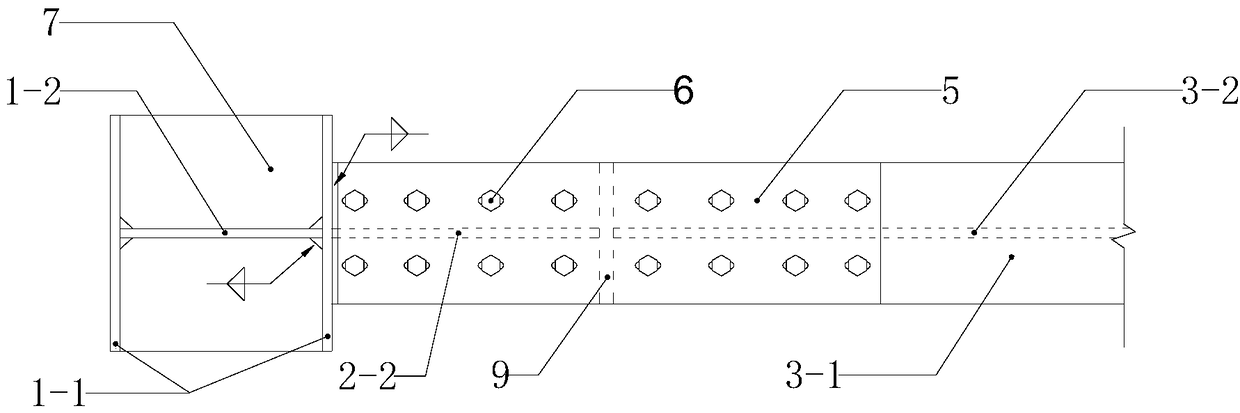

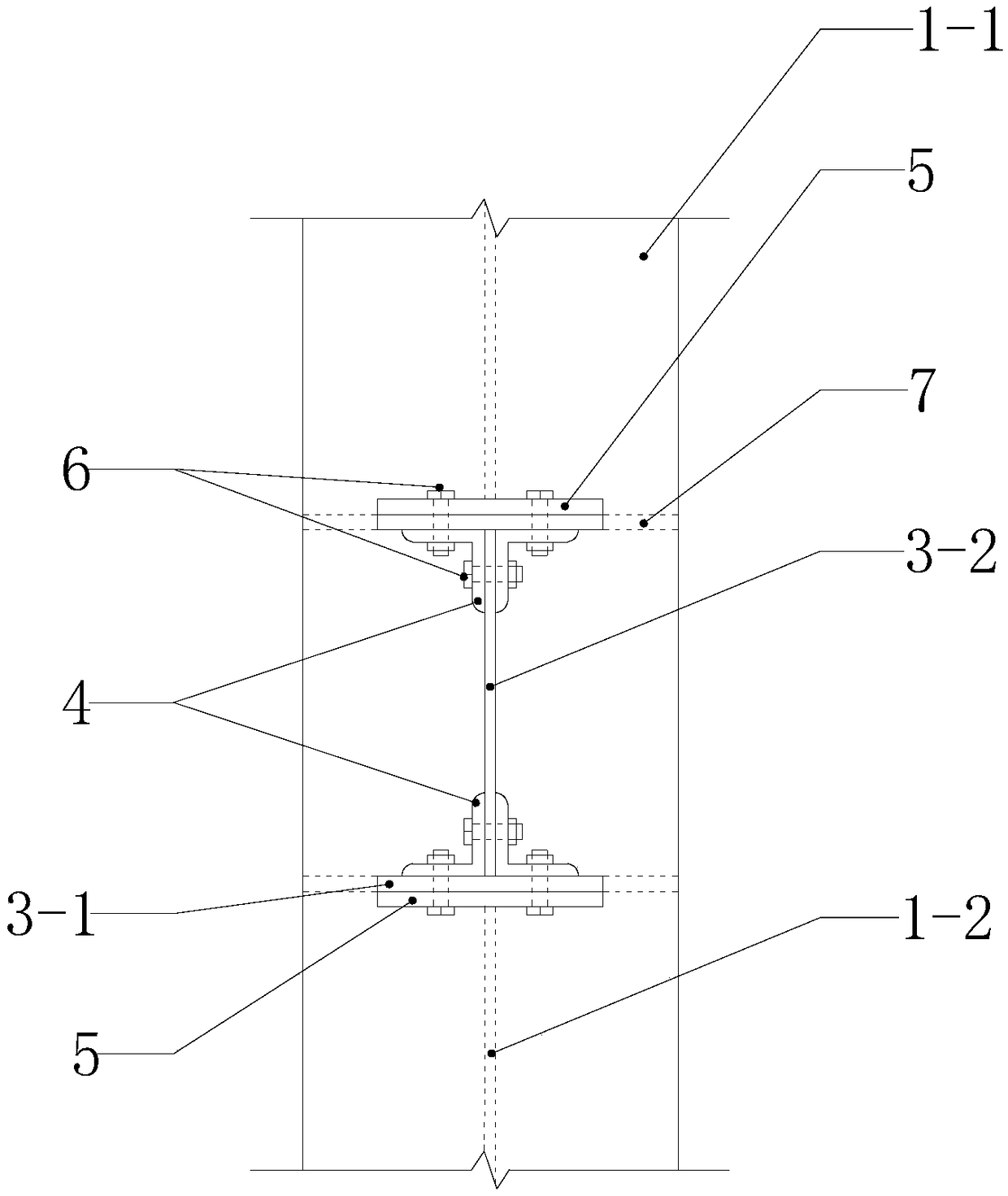

[0036] Such as Figure 1 to Figure 3 As shown, a prefabricated beam-column connection node with recoverable function includes H-shaped steel column 1, H-shaped steel short beam 2, H-shaped steel long beam 3, angle steel 4 and gusset plate 5;

[0037] Wherein, the H-shaped short beam 2 is connected to the column flange 1-1 of the H-shaped steel column 1 by full welding, and the H-shaped steel column 1 and the H-shaped short beam 2 are arranged at right angles.

[0038] Two transverse stiffeners 7 are respectively welded on both sides of the column web 1-2 of the H-shaped steel column 1, and the stiffeners 7 and the flange 2-1 of the H-shaped short beam 2 are located on the same plane. By welding two stiffeners at the position corresponding to the flange of the H-shaped short beam 2 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com