Blowout-preventing upward movement-preventing device for abnormal high pressure operation well and method

An abnormally high pressure, operating well technology, applied in drilling equipment, earthmoving, wellbore/well components, etc., can solve the problem of incomplete unsealing of packers, failure of normal tripping of pipe strings, dead oil and dead wax in oil and water wells and other problems, to achieve the effect of ingenious design, realization of docking and reinforcement, and safety of the governance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

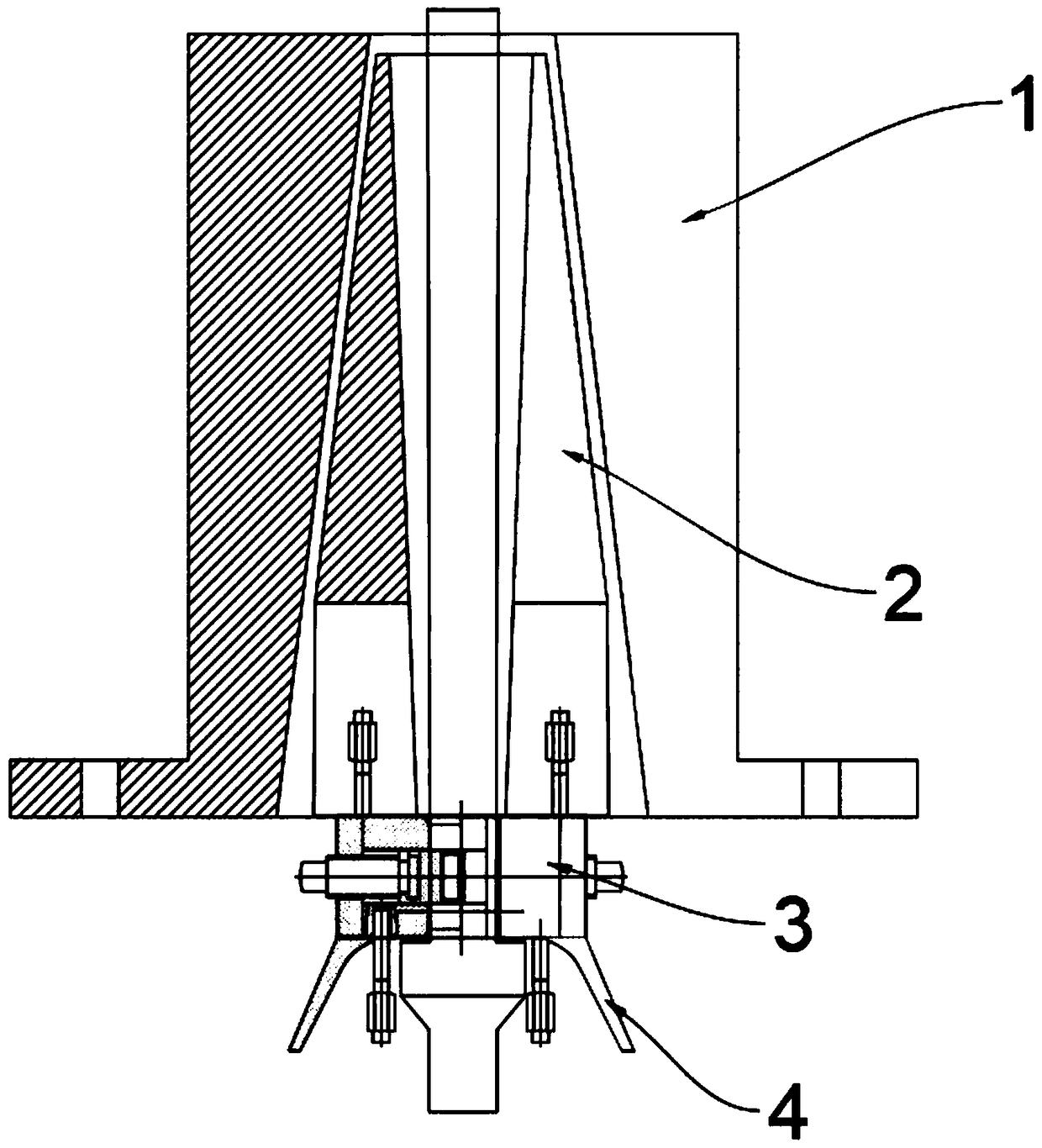

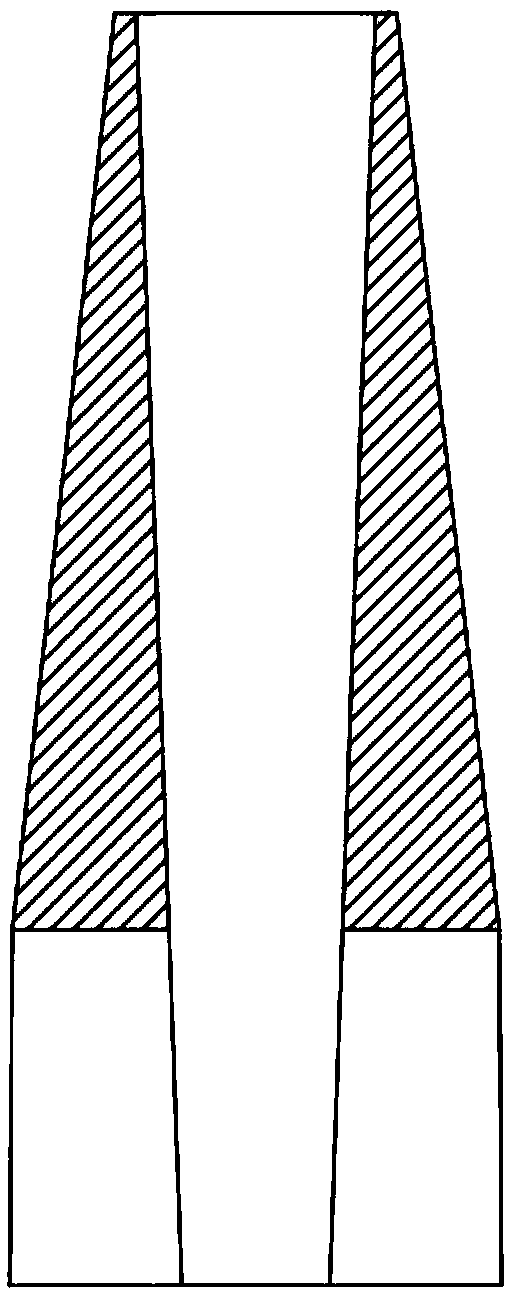

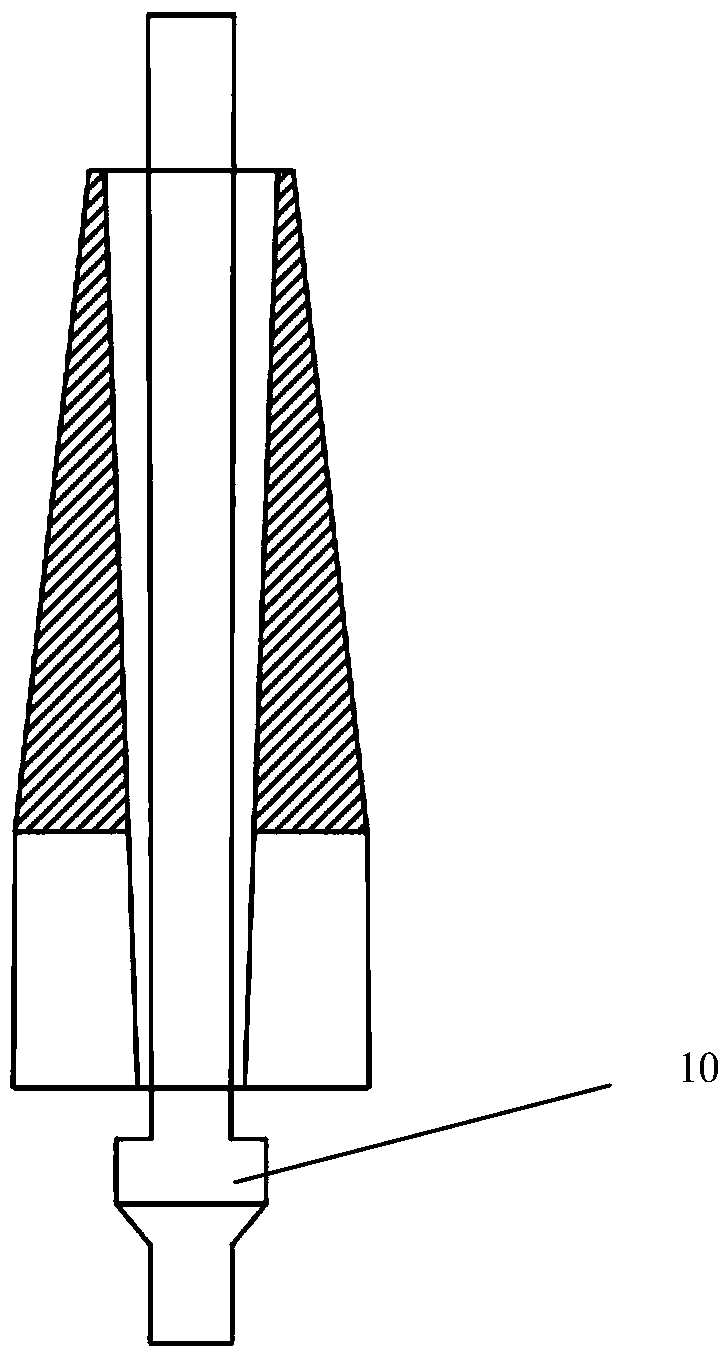

[0018] like figure 1 As shown, this kind of anti-roof and anti-channeling device for abnormal high-pressure operation wells includes a cast iron cylinder body 1, an anti-channeling core body 2, a safety slip 3 and a guide groove 4; wherein, the anti-channeling core body is made of rubber, and the anti-channeling core body The purpose of increasing the circumferential stress area of the oil pipe is achieved. The safety slip 3 includes a safety slip housing 5, the safety slip housing 5 has a gap, the safety slip housing 5 has several round holes in the vertical direction, and the bolts pass through the round holes and The upper anti-channeling core body 2 is connected; the safety slip shell 5 is equipped with two slips 6 with semicircular openings, and the two slips 6 can be combined into a circle; the inside of the two slips 6 has locking teeth , used to clamp the pipe s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com