Open fire stove smoke recycling device

A flue gas recovery and open flame furnace technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of exhaust heat loss and recovery of flue gas waste heat, etc., to achieve heat recovery effect, reasonable design, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

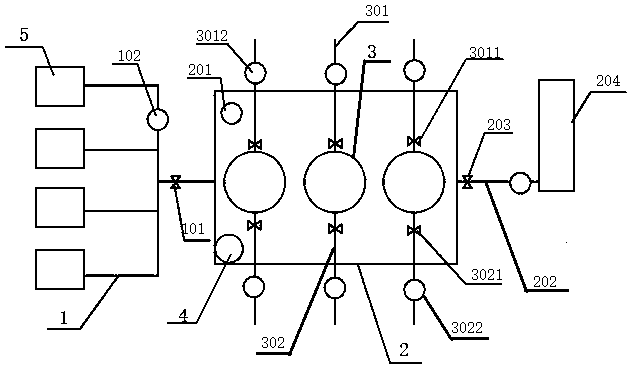

[0022] An open flame furnace flue gas recovery device, comprising a gas collection pipe 1, a heat exchange housing 2, a water storage device 3 and a control device 4, the heat exchange housing 2 is provided with a water inlet pipe relief hole, a water outlet pipe relief hole, Gas-collecting pipe relief hole and exhaust pipe relief hole; gas-gathering pipeline 1 is provided with gas-gathering electromagnetic valve 101 and gas-gathering temperature gauge 102; The air collecting pipe relief hole is connected; the heat exchange shell 2 is provided with a heat exchange shell temperature gauge 201; the exhaust pipe relief hole is provided with an exhaust pipe 202, and the exhaust pipe 201 is provided with an exhaust solenoid valve 203, The exhaust pipe 202 is connected with a chimney 204; the water storage device 3 is provided with a water inlet pipe 301 and a water outlet pipe 302; Valve 3021 and outlet water temperature gauge 3022, gas collection solenoid valve 101, gas collection...

Embodiment 2

[0024] The water inlet pipe relief hole, the water outlet pipe relief hole, the gas collection pipe relief hole and the exhaust pipe relief hole are respectively provided with sealing rings. The material of the sealing rings is rubber, and the rest are consistent with Embodiment 1.

Embodiment 3

[0026] Gas-collecting pipeline 1 is provided with several, all the other are consistent with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com