Numerical control programming method of steam turbine blade processing

A technology of steam turbine blades and numerical control programs, applied in the field of numerical control programming, can solve problems such as error-prone, low efficiency, cumbersome numerical control program preparation, etc., and achieve the effects of improved preparation efficiency, high efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

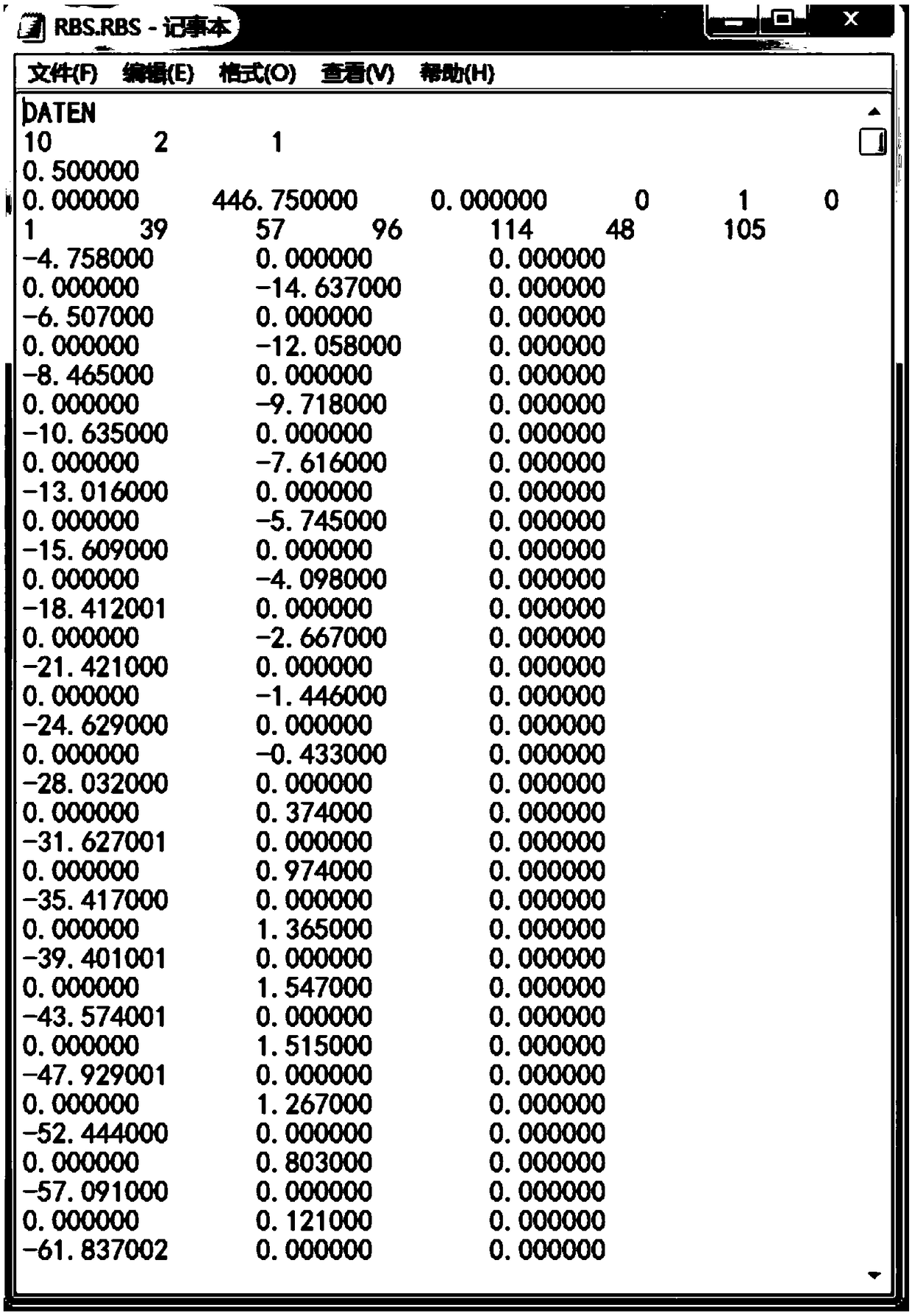

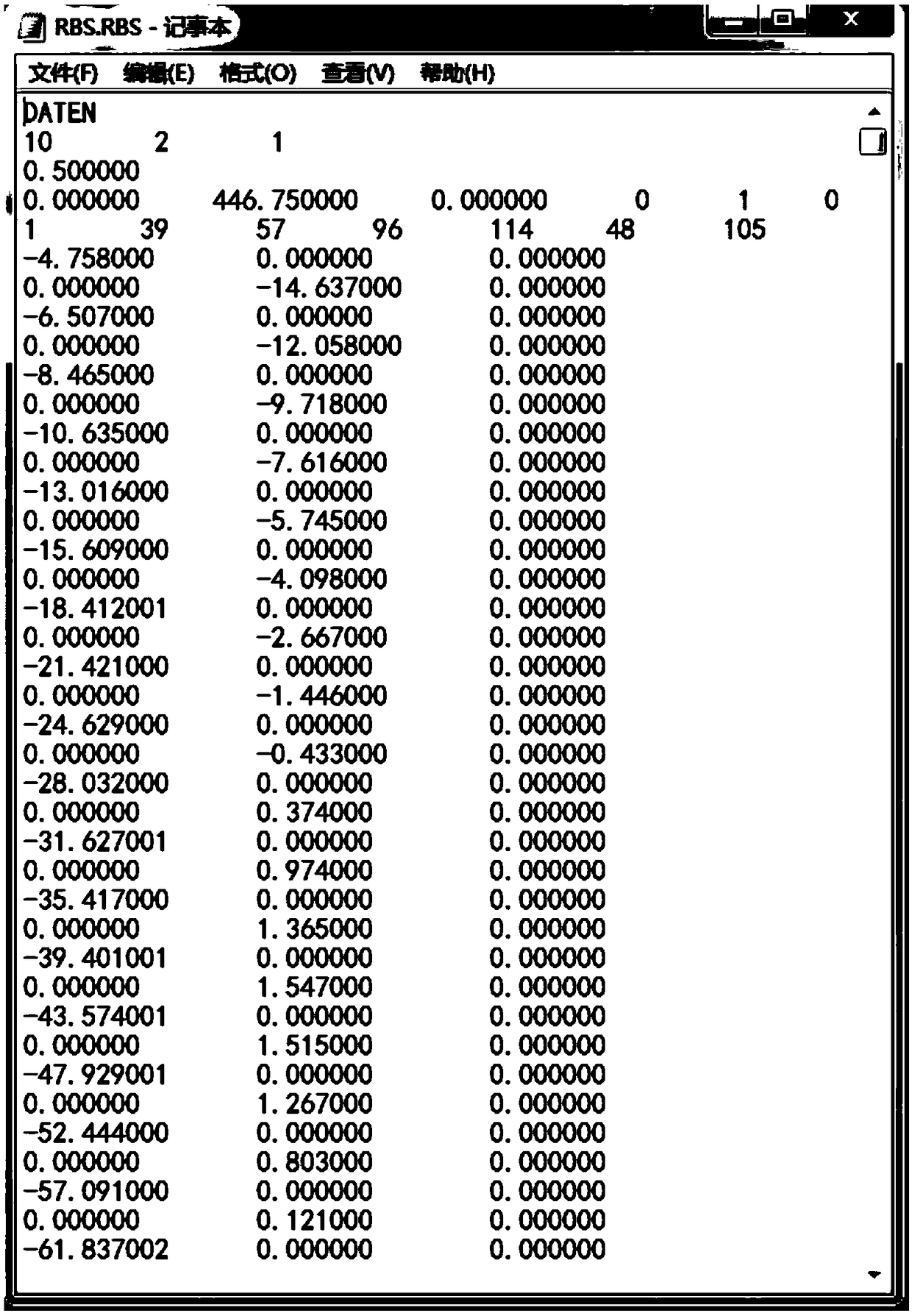

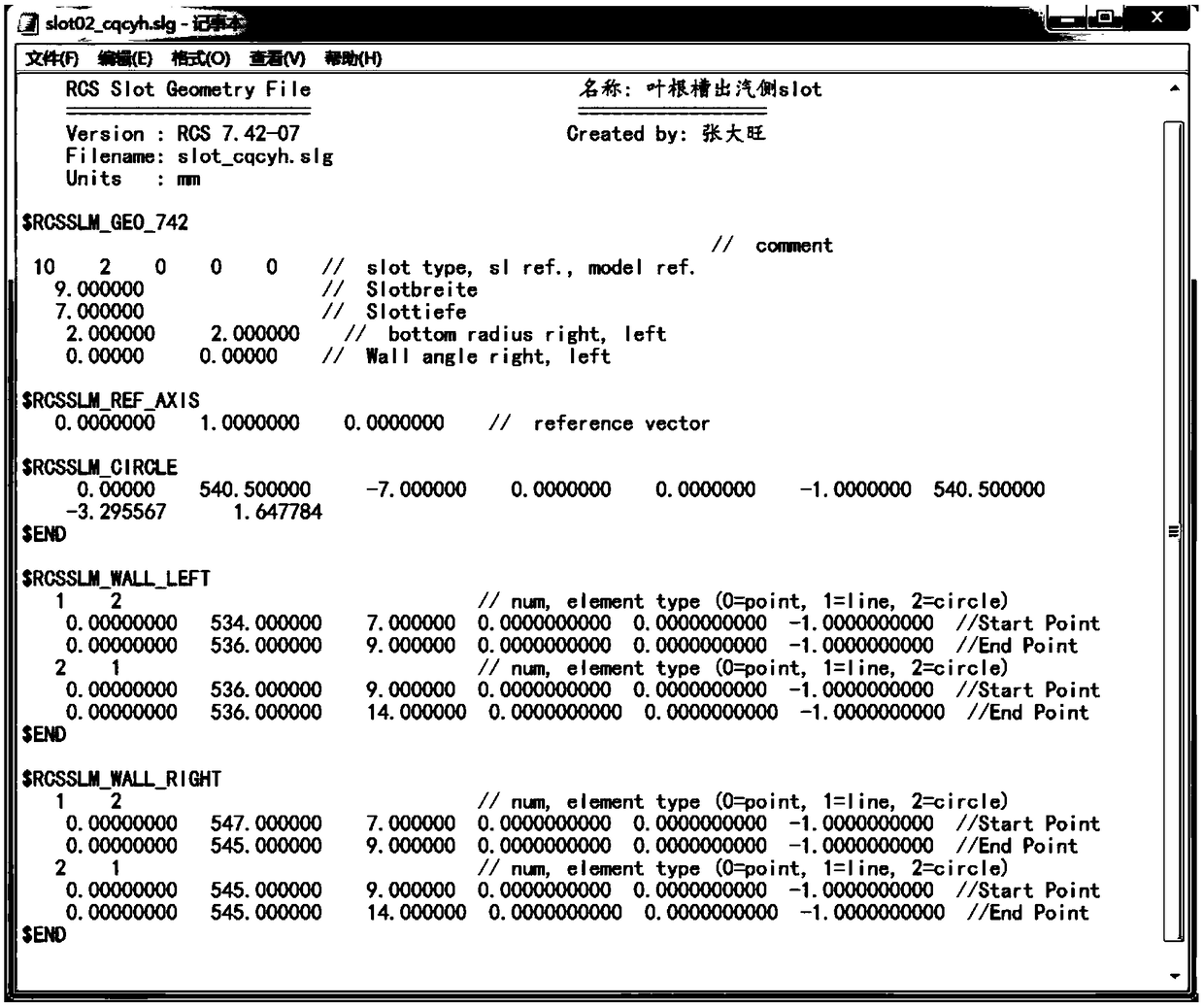

[0018] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 The present embodiment is described. The numerical control programming method for steam turbine blade machining provided in the present embodiment specifically includes the following steps:

[0019] Step 1, carry out secondary development to UG (Unigraphics NX) three-dimensional software, compile plug-in, utilize the RBS, RES, SLG file that the RCS programming of numerical control program RCS programming needs of automatic output of plug-in; Described RBS file is used for defining steam path data, as figure 1 shown; the RES file is used to define the characteristics of the root cap of the blade and the data of each surface, such as figure 2 As shown; the SLG file is used to define the blade groove characteristics, such as image 3 shown;

[0020] Step 2: Replace the output RBS, RES, SLG files with the corresponding files in the NC program RCS, replace the original files, and then...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the described compiling plug-in, utilizes plug-in to realize the step of RBS, RES, SLG file required for automatic output numerical control program RCS programming specifically includes:

[0024] Step 11, extract the data parameters of the three-dimensional model; these data include the four sides of the root crown of the blade, the conical surface of the blade transfer, straight grooves, arc grooves, steam channels, and blanks.

[0025] Step 1 and 2, filter out the required data;

[0026] Step 13: According to the data file format of the software, perform data calculation and logical judgment, and output the obtained results to the corresponding RBS, RES, SLG files.

[0027] UGAPI+C language is used to compile the UG plug-in, and the program code part is as follows:

[0028]

[0029]

[0030]

[0031] Other steps and parameters are the same as those in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com