Preparation method for multi-pore-passage hollow carbon nanosphere compound electrode material

A carbon nanosphere and composite electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of low capacity retention rate of lithium-sulfur batteries, and achieve the goal of improving capacity retention rate, enhancing conductivity, and reducing electrode structure changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

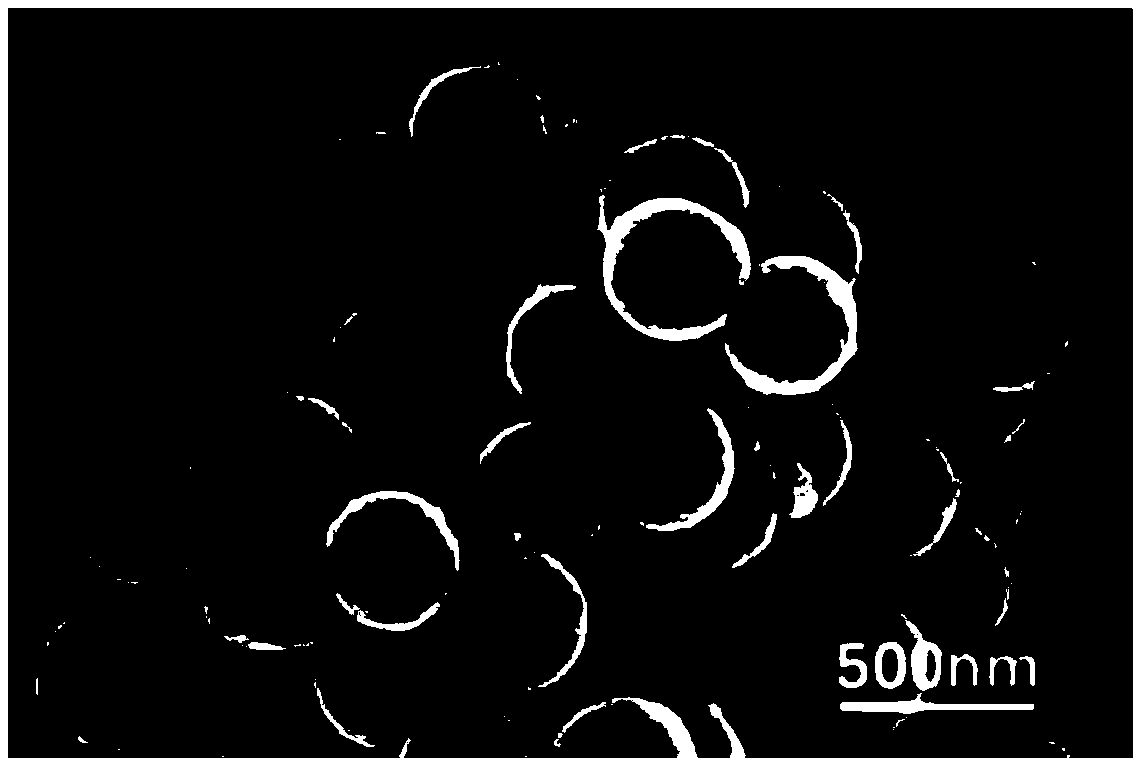

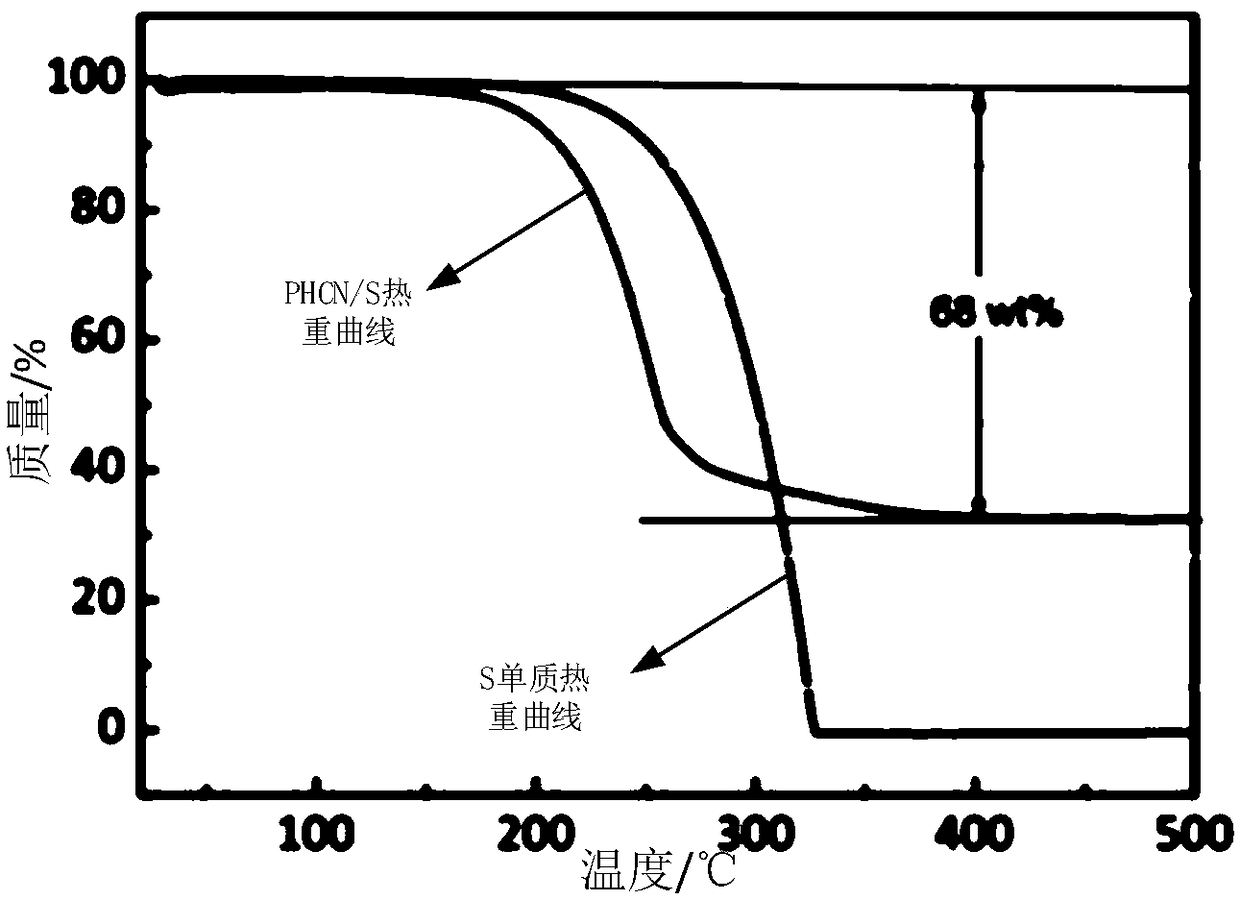

[0025] Pour 75ml of ethanol and 25ml of deionized water into a beaker, add 6ml of tetraethyl orthosilicate, and keep stirring. After the solution is uniform, slowly add 3ml of ammonia water, and stir at room temperature for 2 hours. The resulting product was subjected to high-speed centrifugation, and continuously washed with deionized water and ethanol until the pH of the solution was 7, and the product was dried in a vacuum oven at 60°C for 24 hours to obtain SiO 2 template;

[0026] At room temperature, 1.5g SiO 2 Disperse the template into a mixed solution of deionized water and ethanol with a volume ratio of 1:1, then add an appropriate amount of CTAB and stir evenly; add 3g terephthalaldehyde and 3g hydroquinone to the above suspension, and continue stirring for a period of time , adding 0.9 g of ammonia water, and then continuously stirring at 60° C. for 1 h, then centrifuging the product with a high-speed centrifuge, and washing it twice with deionized water. The was...

Embodiment 2

[0029] Pour 70ml of ethanol and 20ml of deionized water into a beaker, add 5ml of ethyl orthosilicate, and keep stirring. After the solution is uniform, slowly add 2.5ml of ammonia water, and stir at room temperature for 2 hours. The resulting product was subjected to high-speed centrifugation, and continuously washed with deionized water and ethanol until the pH of the solution was 7, and the product was dried in a vacuum oven at 65°C for 24 hours to obtain SiO 2template;

[0030] At room temperature, 4gSiO 2 Disperse the template into a mixed solution of deionized water and ethanol with a volume ratio of 1:1.5, then add an appropriate amount of CTAB and stir evenly; add 8g terephthalaldehyde and 8g hydroquinone to the above suspension, and continue stirring for a period of time , adding 3 g of ammonia water, then centrifuging the product with a high-speed centrifuge after continuous stirring at 55° C. for 1 h, and washing twice with deionized water. The washed product was ...

Embodiment 3

[0033] Pour 75ml of ethanol and 25ml of deionized water into a beaker, add 8ml of tetraethyl orthosilicate, and keep stirring. After the solution is uniform, slowly add 4ml of ammonia water, and stir at room temperature for 2 hours. The resulting product was subjected to high-speed centrifugation, and continuously washed with deionized water and ethanol until the pH of the solution was 7, and the product was dried in a vacuum oven at 60°C for 24 hours to obtain SiO 2 template;

[0034] At room temperature, 1.2gSiO 2 Disperse the template into a mixed solution of deionized water and ethanol with a volume ratio of 1:1, then add an appropriate amount of CTAB and stir evenly; add 2g terephthalaldehyde and 2g hydroquinone to the above suspension, and continue stirring for a period of time , adding 0.5 g of ammonia water, and then continuously stirring at 60° C. for 1 h, centrifuging the product with a high-speed centrifuge, and washing twice with deionized water. The washed produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com