Fish balls and making method thereof

A technology of fish balls and surimi, applied in the field of fish balls and its preparation, can solve the problems of high fat content, easy deterioration, and easy leakage of juice, etc., and achieve the effects of reducing fat content, improving quality, and enriching taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

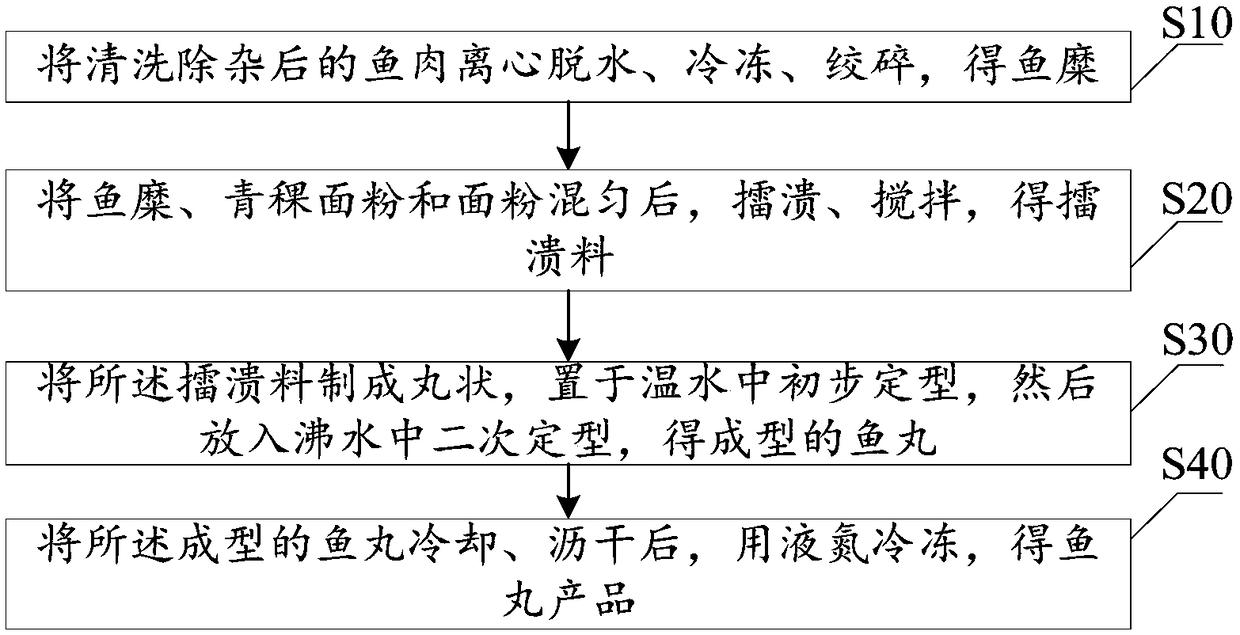

[0039] In addition, the present invention also proposes a method for preparing fish balls, combining figure 1 The schematic flow chart of an embodiment of the preparation method of provided fish balls, as can be seen, the preparation method of described fish balls comprises the following steps:

[0040] Step S10 , centrifuge dehydrating, freezing, and mincing the cleaned and removed fish meat to obtain surimi.

[0041] Wherein, the temperature during freezing is -5°C to -10°C.

[0042] The fish meat used to prepare the fish balls can be any edible fish meat, including freshwater fish and marine fish. For the convenience of processing, fish with high meat content, less fish bones and easy processing can be selected. Before step S10 is implemented, the fish needs to be pretreated to make clean fish meat with bony spurs, anti-connective tissue, mucous membranes and other impurities removed. The specific operations can be as follows:

[0043] After removing the scales, heads, v...

Embodiment 1

[0068] Centrifuge and dehydrate the fish meat after cleaning and removing impurities, freeze at -5°C, and mince to obtain surimi. Kneading at a temperature of 2°C to 8°C: Mix 500g surimi, 300g highland barley flour and 300g high-gluten flour, and then grind for 4 minutes, then add 22g of salt, grind for 8 minutes with salt, then add seasonings, and grind for 10 minutes After that, send it into the mixer and stir for 10 minutes to obtain a crushed material. After the crushed material is made into pellets (each fish ball is about 25g), put it in warm water at 40°C and heat it for 12 minutes, then take it out, put it in boiling water at 95°C and heat it for 18 minutes to get shaped fish balls. The formed fish balls are cooled in ice water, then taken out and drained, and then put into a liquid nitrogen tunnel machine for ultra-low temperature rapid freezing to obtain fish ball products.

Embodiment 2

[0070] Centrifuge and dehydrate the fish meat after cleaning and removing impurities, freeze at -10°C, and mince to obtain surimi. Kneading at a temperature of 2°C to 8°C: Mix 500g of surimi, 300g of 100-mesh highland barley flour and 300g of flour, and then grind for 5 minutes in the air, then add 33g of salt, and grind for 7.5 minutes with salt, then add seasoning, seasoning After beating for 14 minutes, send it into a mixer and stir for 13 minutes to obtain a beating material. After the crushed material is made into pellets (each fish ball is about 25g), put it in warm water at 60°C and heat it for 10 minutes, then remove it, put it in boiling water at 100°C and heat it for 15 minutes to get shaped fish balls. The formed fish balls are cooled in ice water, then taken out and drained, and then put into a liquid nitrogen tunnel machine for ultra-low temperature rapid freezing to obtain fish ball products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com