Electrochemical treatment method for organic waste water

A technology of organic wastewater and treatment methods, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of affecting the electrolysis speed, slow speed, and sewage adhesion on the electrode plate, etc. Achieve the effect of increasing the electrolysis speed, maintaining the electrolysis speed, and improving the sewage treatment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

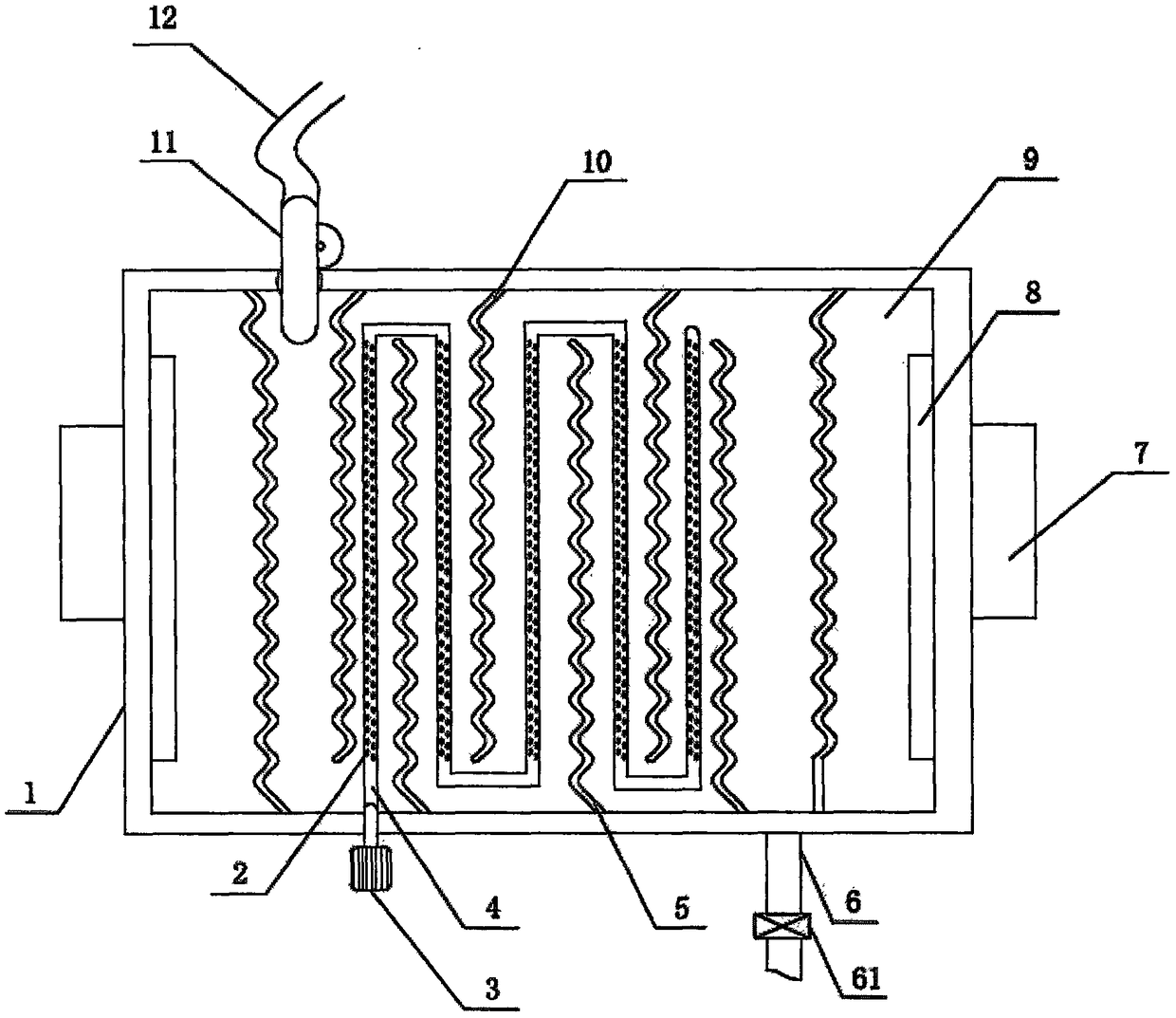

[0032] 1. An electrochemical treatment method for organic waste water, comprising the steps of:

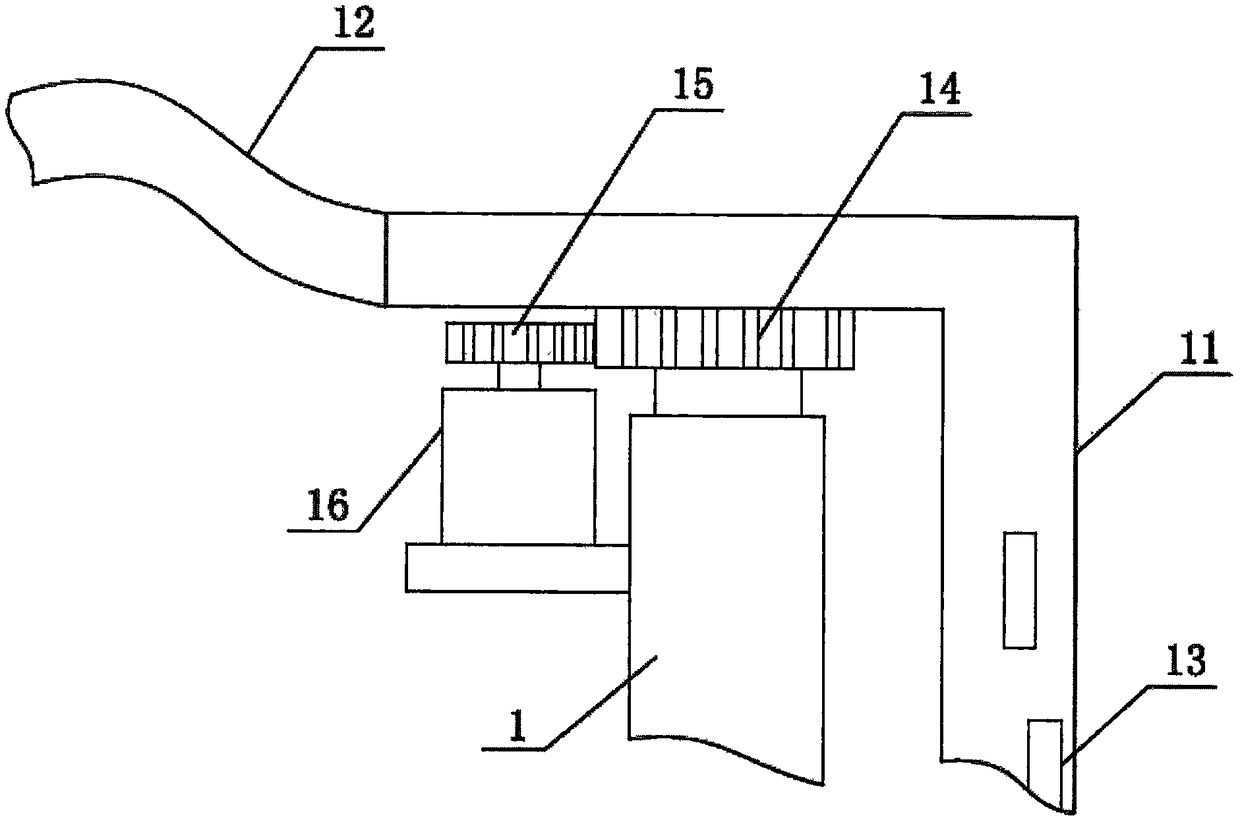

[0033] S1, check the equipment, confirm that the driving motor 16, the ultrasonic generator 7, the air pump 3 and the drain valve 61 are normal;

[0034] S2, add pure water, inject pure water into the pure water area 9 at both ends of the insulating water tank 1, open the ultrasonic generator 7, and start working;

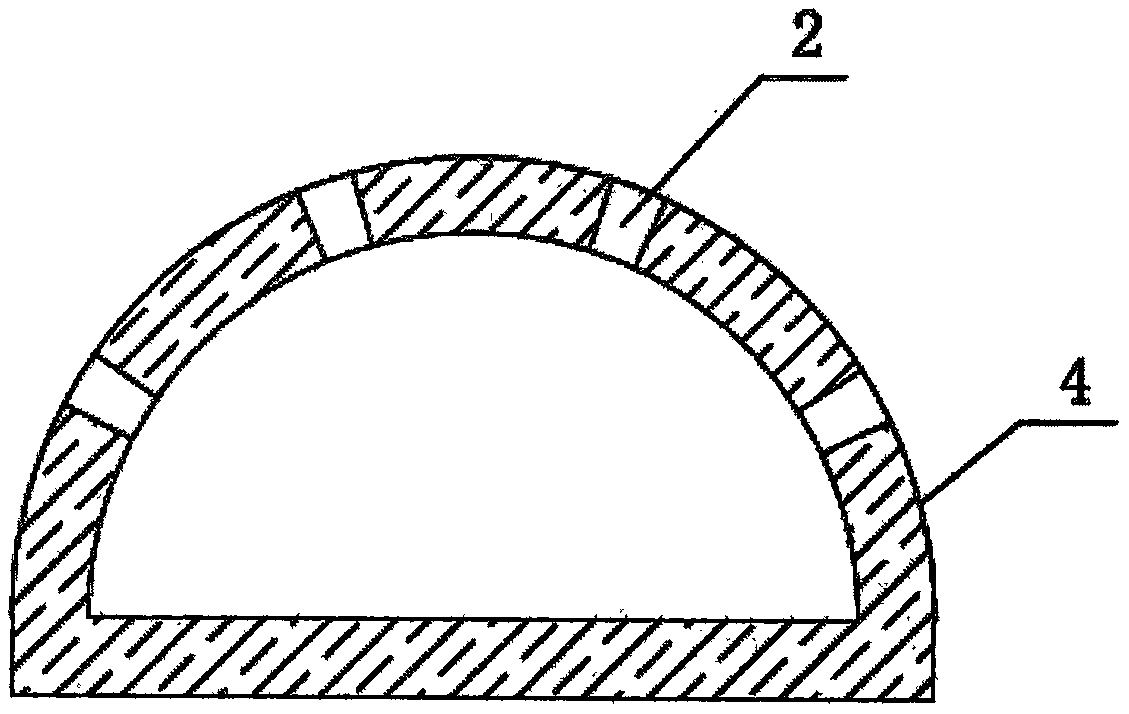

[0035] S3. Sewage injection. The sewage is guided into the insulating water tank 1 through the water inlet pipe 11. When the water level reaches half of the inner depth of the insulating water tank 1, the air pump 3 is turned on for aeration;

[0036] S4, energize, turn on the power supply to energize the wave-shaped anode electrode plate 5 and the wave-shaped cathode electrode plate 10 respectively;

[0037] S5, dosing, drop into environment-friendly ultrasonic cleaning liquid and antiscalant from water inlet pipe 11;

[0038] S4, start the drive motor 16, adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com