Oil-resistant silicone rubber compound and preparation method thereof

A technology of silicone rubber and mixed rubber, which is applied in the field of silicone rubber, can solve the problems of obvious swelling, poor oil resistance and solvent resistance, and limit applications, and achieve the effect of improving oil resistance, ensuring oil resistance, and reducing volume change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

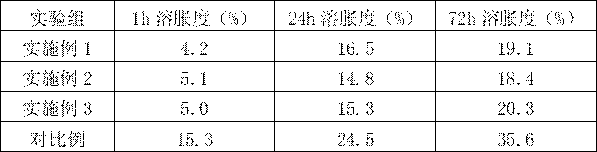

Examples

Embodiment 1

[0027] An oil-resistant silicone rubber compound, the raw materials of which include: 100 parts by mass of methyl vinyl silicone rubber, 3 parts by mass of fluorine-containing silicone oil, 45 parts by mass of polytetrafluoroethylene, 20 parts by mass of diatomaceous earth, 75 parts by mass of white carbon black Parts by mass, 2 parts by mass of vinyltriethoxysilane as a coupling agent, 10 parts by mass of hydroxyl silicone oil JS-209J as a structure treatment agent, and 1 part by mass of heat-resistant agent iron oxide-coated titanium oxide.

[0028] Prepared by:

[0029] (1) Add methyl vinyl silicone rubber, fluorine-containing silicone oil, and silane coupling agent into the kneader in proportion to knead for 10-20 minutes;

[0030] (2) Add white carbon black, polytetrafluoroethylene, structure treatment agent and diatomaceous earth in 3 times, fully knead after each addition, and obtain silicone rubber compound;

[0031] (3) Heat up the silicone rubber compound to 140°C, ...

Embodiment 2

[0034] An oil-resistant silicone rubber compound, the raw materials of which include: 100 parts by mass of methyl vinyl silicone rubber, 5 parts by mass of fluorine-containing silicone oil, 30 parts by mass of polytetrafluoroethylene, 30 parts by mass of diatomite, and 40 parts by mass of white carbon black parts by mass, 5 parts by mass of coupling agent vinyltriethoxysilane, 5 parts by mass of hydroxy silicone oil JS-209J as a structure treatment agent, and 3 parts by mass of heat-resistant agent iron oxide-coated titanium oxide.

[0035] Prepared by:

[0036] (1) Add methyl vinyl silicone rubber, fluorine-containing silicone oil and silane coupling agent into the kneader in proportion and knead for 20 minutes;

[0037] (2) Add white carbon black, polytetrafluoroethylene, structure treatment agent and diatomaceous earth in 4 times, fully knead after each addition, and obtain a silicone rubber compound;

[0038] (3) Heat up the silicone rubber mix to 160°C, knead evenly in v...

Embodiment 3

[0041] An oil-resistant silicone rubber compound, the raw materials of which include: 100 parts by mass of methyl vinyl silicone rubber, 10 parts by mass of fluorine-containing silicone oil, 30 parts by mass of polytetrafluoroethylene, 10 parts by mass of diatomaceous earth, 60 parts by mass of white carbon black parts by mass, 8 parts by mass of coupling agent vinyltriethoxysilane, 20 parts by mass of hydroxy silicone oil JS-209J as a structure treatment agent, and 5 parts by mass of heat-resistant agent iron oxide-coated titanium oxide.

[0042] Prepared by:

[0043] (1) Add methyl vinyl silicone rubber, fluorine-containing silicone oil and silane coupling agent into the kneader in proportion and knead for 20 minutes;

[0044] (2) Add white carbon black, polytetrafluoroethylene, structure treatment agent and diatomaceous earth in 4 times, fully knead after each addition, and obtain a silicone rubber compound;

[0045] (3) Heat up the silicone rubber mix to 150°C, knead even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com