Forged semi-high-speed steel intermediate roll and manufacturing method thereof

A technology of semi-high-speed steel and manufacturing methods, which is applied in the field of roll preparation, can solve problems such as the increase in roll purchase costs, and achieve the effect of not reducing the service period, ensuring the service period, and ensuring smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

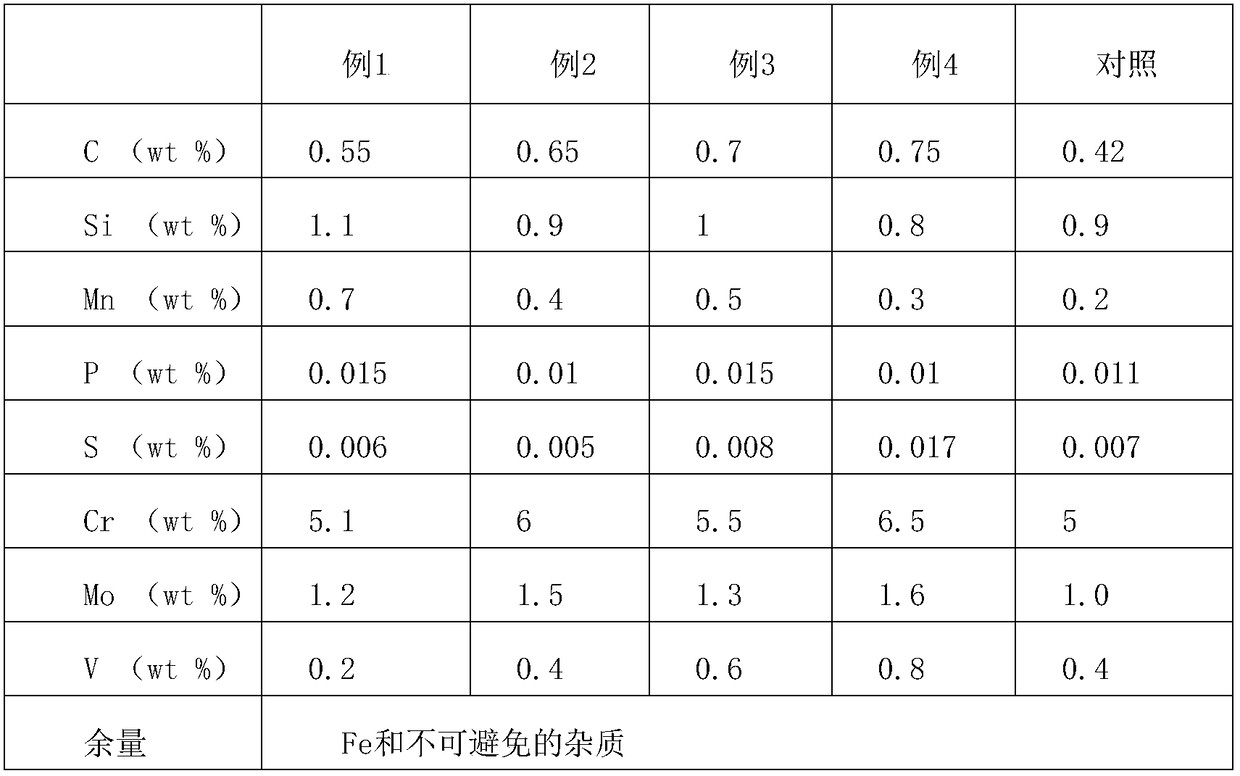

[0032] Example 1: A forged semi-high-speed steel intermediate roll. The chemical components and contents contained in the material of the intermediate roll are shown in Table 1. The diameter of the intermediate roll is 280 mm, and the length of the intermediate roll is 3000 mm. The preparation steps of the intermediate roll are: prepare the intermediate roll blank according to the chemical composition and content of the above-mentioned intermediate roll material, and rough-turn the blank; then perform quenching and tempering treatment, heat the rough-turned blank to 920°C Under heat preservation for 8 hours, then quenching and tempering treatment; quenching and tempering treatment adopts water cooling and quenching, and then tempering, the tempering temperature is 640 ° C, and the tempering holding time is 15 hours; after that, quenching heat treatment is carried out, quenching is carried out by using double intermediate frequency induction furnace, scanning The heating tempera...

Embodiment 2

[0033] Example 2: A forged semi-high-speed steel intermediate roll. The chemical components and contents contained in the material of the intermediate roll are shown in Table 1. The diameter of the intermediate roll is 320 mm, and the length of the intermediate roll is 3500 mm. The preparation steps of the intermediate roll are: prepare the intermediate roll blank according to the chemical composition and content of the above-mentioned intermediate roll material, and rough-turn the blank; then perform quenching and tempering treatment, heat the rough-turned blank to 950°C Under heat preservation for 4 hours, quenching and tempering treatment adopts water cooling and quenching, and then tempering, the tempering temperature is 620°C, and the tempering holding time is 15 hours; after that, quenching heat treatment is carried out, quenching is carried out by double intermediate frequency induction furnace, and the scanning heating temperature is 980 ℃, the scanning speed is 48mm / mi...

Embodiment 3

[0034] Example 3: A forged semi-high-speed steel intermediate roll. The chemical components and contents contained in the material of the intermediate roll are shown in Table 1. The diameter of the intermediate roll is 360 mm, and the length of the intermediate roll is 3500 mm. The preparation steps of the intermediate roll are: prepare the intermediate roll blank according to the chemical composition and content of the above-mentioned intermediate roll material, and rough-turn the blank; then perform quenching and tempering treatment, heat the rough-turned blank to 900°C Keep warm for 6 hours. After the heat preservation is completed, perform water cooling and quenching, and then temper. The tempering temperature is 600 ° C, and the tempering holding time is 20 hours. ℃, the scanning speed is 36mm / min; after quenching, temper at medium temperature, the tempering temperature is 380℃, and the holding time is 25h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com