Lithium extractant and method for extracting lithium from salt lake brine

A salt lake brine and extraction agent technology, applied in the field of extraction chemistry, can solve problems affecting the fluidity and phase separation of the extraction system, low solubility, and shortening the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

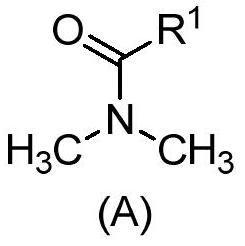

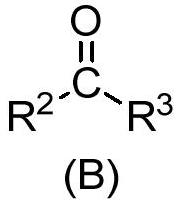

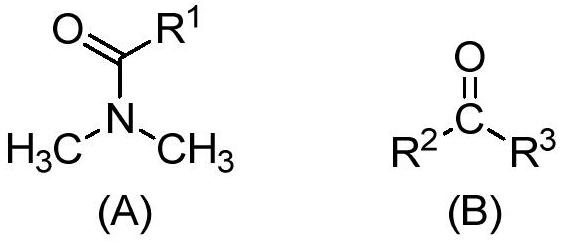

Image

Examples

Embodiment 1

[0100] Treat the salt lake brine with the composition shown in Table 1 according to the general method, in which the extracted organic phase is a mixture of N,N-dimethyloctylamide and D70 solvent oil, with volume fractions of 40% and 60%, respectively; as shown in Table 1 FeCl added to brine 3 Mix and dissolve and make Fe / Li=1.5 (molar ratio) as the extracting liquid; extraction O / A=2.0; washing O / A=30; stripping agent: 6mol / L HCl, stripping O / A=30; regeneration Reagent: 0.5mol / L NaOH solution, regeneration O / A=20.

[0101] After extraction, the system is divided into three clear and transparent phases. The single-stage lithium extraction rate is 61.5%, and the single-stage lithium-magnesium separation coefficient (β Li / Mg ), lithium sodium separation coefficient (β Li / Na ), lithium potassium separation coefficient (β Li / K ) Reached 285.3, 21.5 and 37.7 respectively. After 6 levels of extraction, 5 levels of washing, 5 levels of back extraction, the recovery rate of lithium i...

Embodiment 2

[0103] The salt lake brine with the composition shown in Table 1 was treated according to the general method, in which the extracted organic phase was a mixture of N,N-dimethyloctylamide, diisobutyl ketone, and D70 solvent oil, and the volume fractions were 40%, 20%, 40%; FeCl is added to the brine shown in Table 1 3 Mix and dissolve and make Fe / Li=1.5 (molar ratio) as the extracting liquid; extraction O / A=2.0; washing O / A=20; stripping agent: 6mol / L HCl, stripping O / A=30; Regeneration agent: 0.5mol / L NaOH solution, regeneration O / A=20.

[0104] After extraction, the system is divided into two clear and transparent phases without an intermediate phase (third phase). The single-stage lithium extraction rate is 68.7%, and the single-stage lithium-magnesium separation coefficient (β Li / Mg ), lithium sodium separation coefficient (β Li / Na ), lithium potassium separation coefficient (β Li / K ) Reached 310.8, 30.4 and 46.5 respectively. After 5 levels of extraction, 4 levels of wash...

Embodiment 3

[0106] Treat the salt lake brine with the composition shown in Table 1 according to the general method, in which the extracted organic phase is a mixture of N,N-dimethyloctylamide, diisobutyl ketone, and 260# aviation kerosene, with volume fractions of 30% and 30% respectively. %, 40%; Add FeCl to the brine shown in Table 1 3 Mix and dissolve and make Fe / Li=1.3 (molar ratio) as the extracting liquid; extraction O / A=1.0; washing O / A=30; stripping agent: 6mol / L HCl, stripping O / A=30; Regenerant: 0.3mol / L Na 2 CO 3 Solution, regeneration O / A=20.

[0107] After extraction, the system is divided into two phases. The single-stage lithium extraction rate is 55.8%, and the single-stage lithium-magnesium separation coefficient (β Li / Mg ), lithium sodium separation coefficient (β Li / Na ), lithium potassium separation coefficient (β Li / K ) Reached 280.2, 20.3, and 40.5 respectively. After 7 levels of extraction, 5 levels of washing, 5 levels of back extraction, the recovery rate of lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com