Anti-seismic ceramsite lightweight wall board

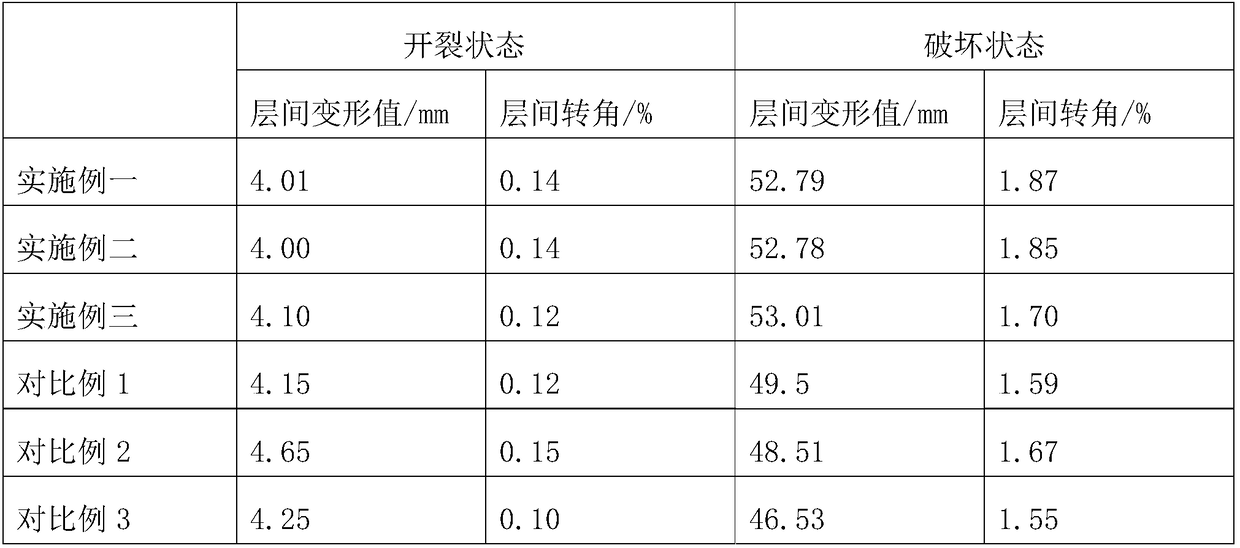

A technology of lightweight wallboard and ceramsite, applied in the field of building wallboard, can solve the problems of poor seismic performance and low stiffness of wallboard, improve ductility parameters and interlayer deformation, improve interlayer rotation angle, and has strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

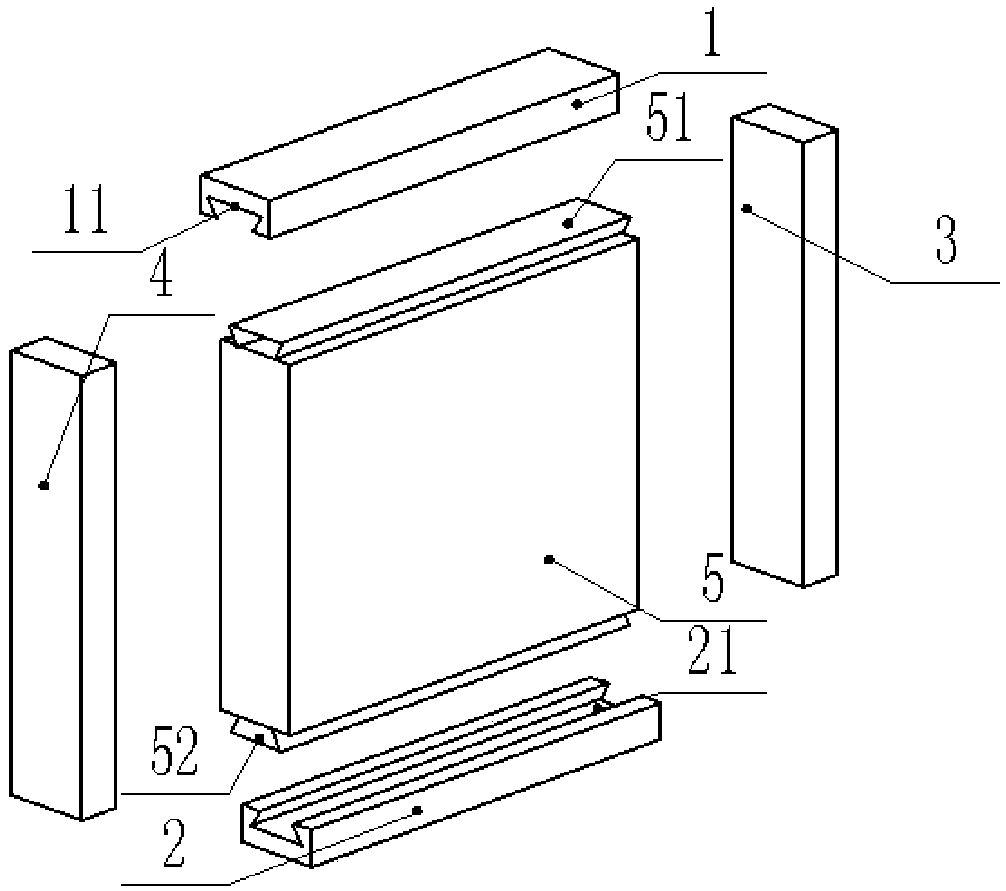

[0028] like figure 1 Shown: Seismic ceramsite lightweight wall panels include:

[0029] A rectangular anti-seismic frame, the anti-seismic frame includes an upper beam 1, a lower beam 2, a left beam 4 and a right beam 3, the upper beam 1 is provided with a first dovetail groove 11, and the lower beam 2 is provided with a second dovetail groove twenty one.

[0030] The cushioning interlayer 5, the upper end of the cushioning interlayer 5 is provided with a first dovetail tenon 51 used in conjunction with the first dovetail groove 11, and the lower end is provided with a second dovetail tenon 52 used in conjunction with the second dovetail groove 21.

[0031] The upper beam 1 and the lower beam 2 are connected with the first dovetail tenon 51 and the second dovetail tenon 52 of the shock-absorbing interlayer 5 through the first dovetail groove 11 and the second dovetail groove 21 respectively. The joints are coated with glue-mixed graphite with a thickness of 3-7mm.

[0032] ...

Embodiment 2

[0042] Compared with Embodiment 1, this embodiment differs only in that the structure of the filling block in the wallboard manufacturing step in this embodiment is different.

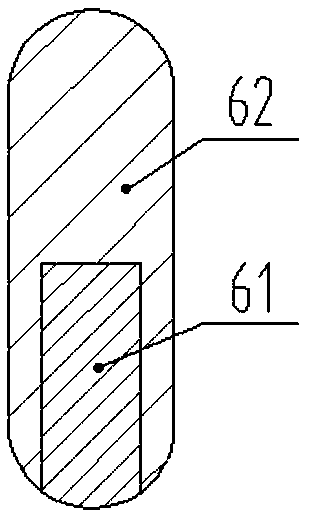

[0043] like figure 2 As shown: the filling block in this embodiment includes a glass tube inner layer 61 and a viscoelastic outer layer 62, the glass tube inner layer 61 and the viscoelastic outer layer 62 are both closed spaces, and the glass tube inner layer 61 is placed with peroxide, viscoelasticity Esters and fluorescent dyes are placed between the outer layer 62 and the inner layer 61 of the glass tube. Specifically, sodium peroxide is used for the peroxide, ethyl acetate is used for the ester compound, and red fluorescent dye is used for the fluorescent dye.

Embodiment 3

[0045] Compared with the first embodiment, this embodiment differs only in that in the pouring step, when pouring the cushioning interlayer, a closed chamber is provided in the cushioning interlayer, and a shear thickening liquid is placed in the chamber.

[0046] Concrete, the preparation method of shear thickening liquid is:

[0047] Add a 20 wt% isocyanate solution and a catalyst to a 35 wt% polyethylene glycol solution, pre-react for 30-50 minutes under reflux conditions, then add a 15 wt% cellulose acetate solution, and mix well React at 80°C for 1-3 hours, distill off the solvent under reduced pressure to obtain the base liquid;

[0048] Add ethyl silicate to tetrapropylammonium hydroxide saturated liquid with a concentration of 25wt%, stir and react at 80°C for 1-3 hours to obtain an additive solution;

[0049] Mix the base liquid and the additive liquid, react at a temperature of 140-160°C and a pressure of 0.5-0.6Mpa for 18-24 hours, and finally distill off the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com